Preparation method of high molecular weight polylactic acid stereocomplex with melt stability

A technology of stereocomplex and melt stability, which is applied in the field of preparation of high-molecular-weight polylactic acid stereocomplex, can solve the problems of poor memory effect, difficult formation of sc, difficulty in forming a large amount or complete sc, etc., and achieves The effect of improving crystallization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

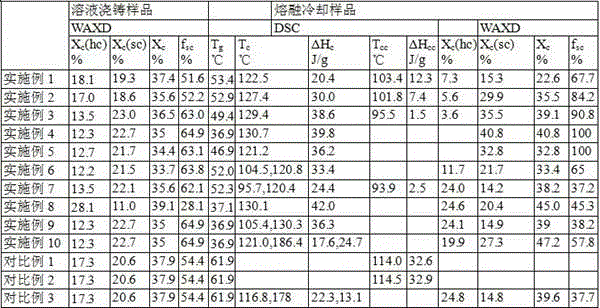

[0025] The weight average molecular weight was 2.1×10 5 g·mol -1 PLLA and 1.0 x 10 5 g·mol -1 PDLA, and a molecular weight of 1000 g·mol -1 PEG was dissolved in dichloromethane at a concentration of 1 g dl -1 . After complete dissolution, mix under vigorous stirring and solution cast at room temperature. PLLA:PDLA=1:1wt in PLLA / PDLA / PEG blend, PEG content is 3wt%. The solution-cast samples were vacuum-dried and heated rapidly at a rate of 100 °C / min under nitrogen protection using a differential scanning calorimeter (DSC), and then cooled slowly at a rate of 10 °C / min to 270 °C for 2 min. The melt-cooled sample was obtained at 0 °C, and the temperature was raised again at a rate of 10 °C / min to detect the crystallization parameters of the melt-cooled sample. The crystal structures of the solution-cast samples and the melt-cooled samples were characterized by wide-angle X-ray diffraction (WAXD).

Embodiment 2

[0027] The weight average molecular weight was 2.1×10 5 g·mol -1 and 1.0×10 5 g·mol -1 PLLA, PDLA, and a molecular weight of 1000 g·mol -1 PEG was dissolved in dichloromethane at a concentration of 1 g dl -1 . After complete dissolution, mix under vigorous stirring and solution cast at room temperature. PLLA:PDLA=1:1wt in PLLA / PDLA / PEG blend, PEG content is 5wt%. The solution-cast samples were vacuum-dried and heated rapidly by DSC at a rate of 100 °C / min under nitrogen protection, and then cooled slowly to 0 °C at a rate of 10 °C / min after isothermally at 270 °C for 2 minutes to obtain a melt-cooled sample, and The temperature was raised again at a rate of 10 °C / min to detect the crystallization parameters of the melt-cooled sample. And by WAXD to characterize the crystal structure of the solution cast sample and the sample after melt cooling.

Embodiment 3

[0029] The weight average molecular weight was 2.1×10 5 g·mol -1 and 1.0×10 5 g·mol -1 PLLA, PDLA, and a molecular weight of 1000 g·mol -1 PEG was dissolved in dichloromethane at a concentration of 1 g dl -1 . After complete dissolution, mix under vigorous stirring and solution cast at room temperature. PLLA:PDLA=1:1wt in PLLA / PDLA / PEG blend, PEG content is 7wt%. The solution-cast samples were vacuum-dried and heated rapidly by DSC at a rate of 100 °C / min under nitrogen protection, and then cooled slowly to 0 °C at a rate of 10 °C / min after isothermally at 270 °C for 2 minutes to obtain a melt-cooled sample, and The temperature was raised again at a rate of 10 °C / min to detect the crystallization parameters of the melt-cooled sample. And by WAXD to characterize the crystal structure of the solution cast sample and the sample after melt cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com