PP-PA6 (polypropylene-polyamide 6) polymer alloy resin for spinning

A technology of PA-6 and alloy resin, which is applied in the direction of conjugated synthetic polymer artificial filament, etc., can solve the problems of difficult forming and achieve the effects of enhanced mechanical properties, heat aging resistance and light aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

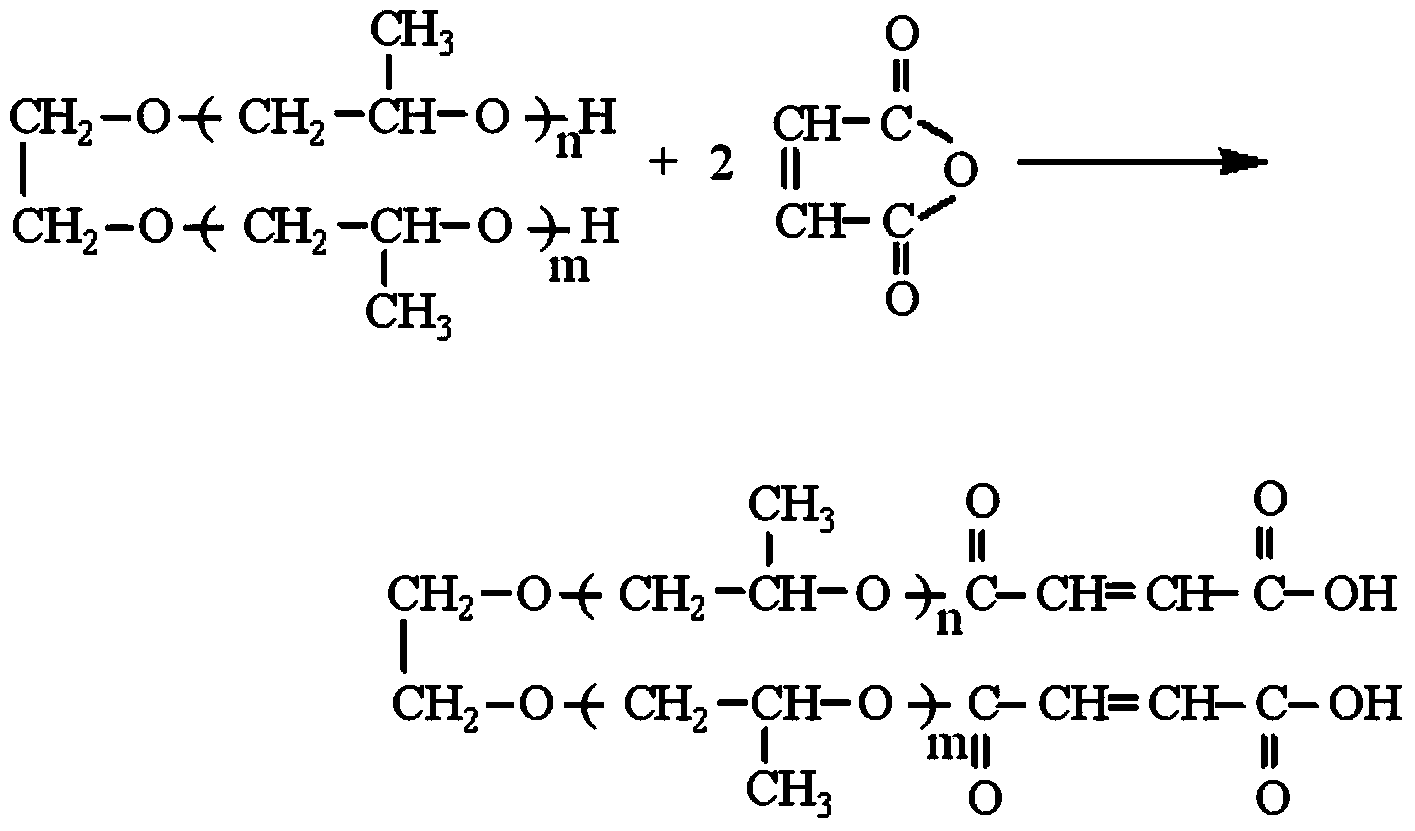

[0020] Put polyether diol and maleic anhydride with twice the molecular weight into a three-necked flask, start stirring, and raise the temperature to 55-60°C. After the maleic anhydride is completely dissolved, the temperature is gradually raised to 110° C., and when the reaction time reaches 3 hours, the reaction ends, and the reactant of maleic anhydride and polyether diol is prepared.

[0021] Chemical reaction equation:

[0022]

[0023] n+m=4, n≥1, m≥1;

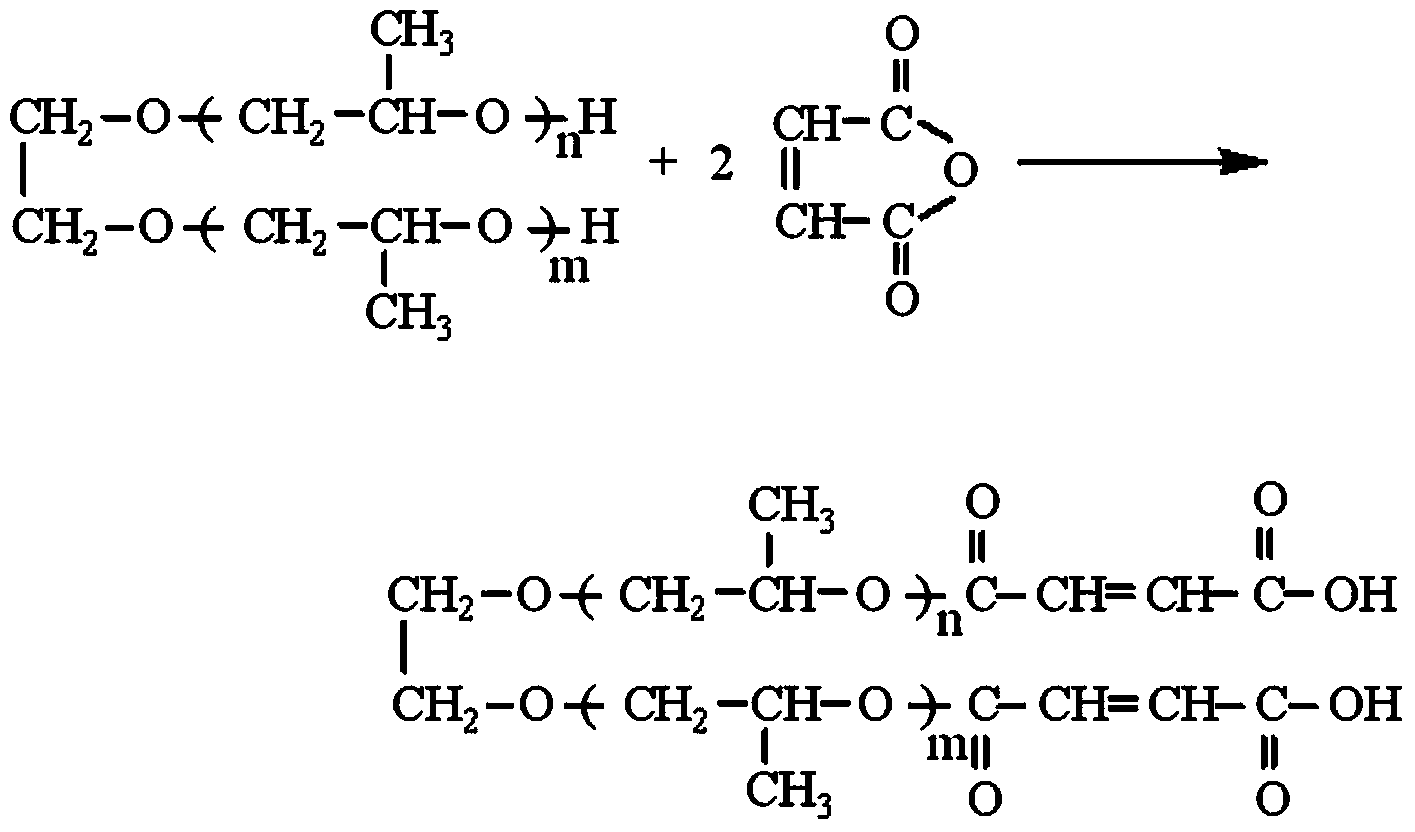

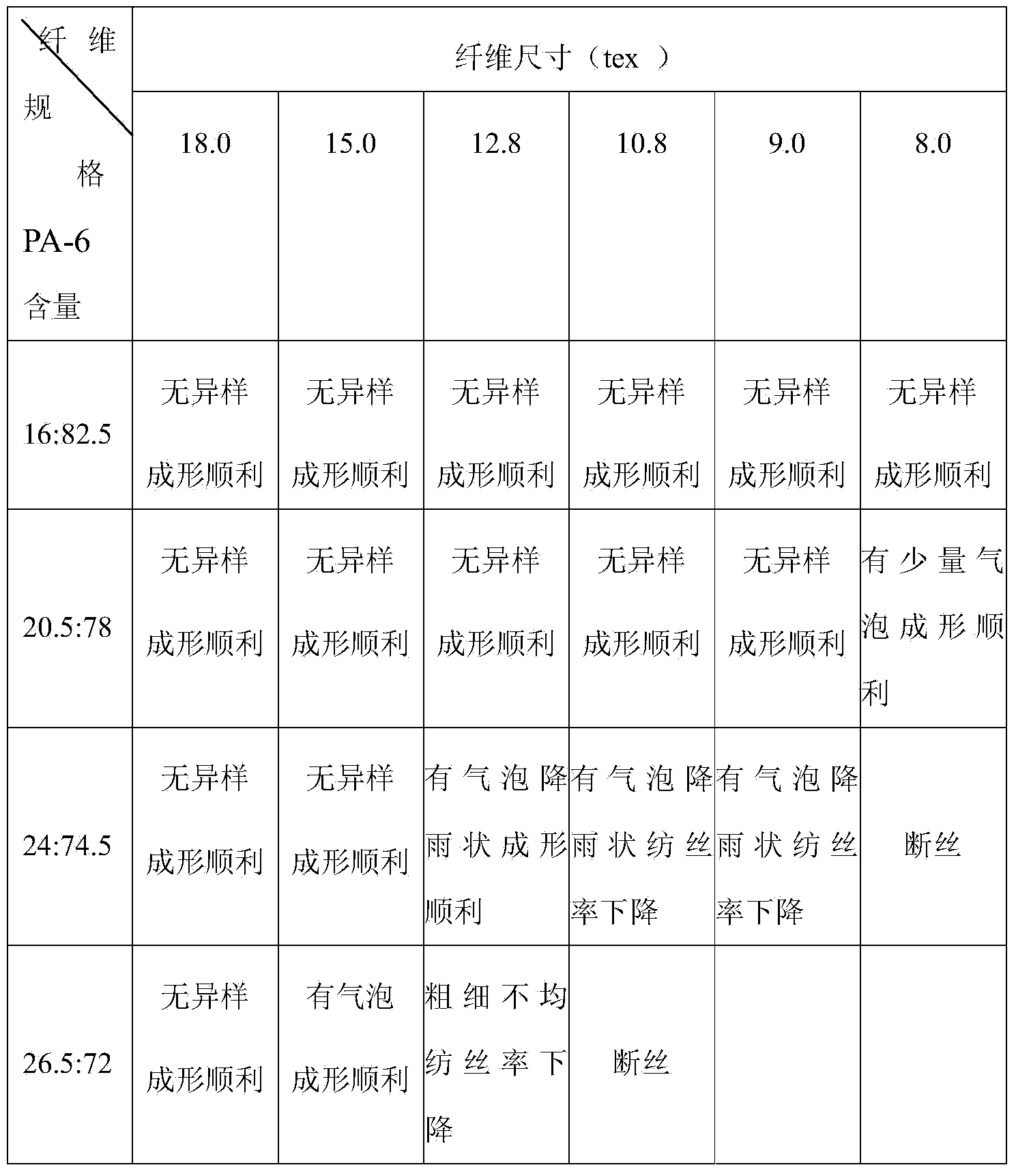

[0024] Weigh 150 grams of maleic anhydride and polyether diol reactant, 5 g of initiator, and 7750 g of polypropylene PP resin, put them into a kneader for blending, add 2100 g of nylon PA-6 resin after the mixture is uniform, and continue mixing. The unloaded material is poured into the feeding port of the twin-screw extruder for extrusion and blending, and is pulled and granulated at the exit of the extruder, and the obtained product is PP / PA-6 polymer alloy.

[0025] The features of the present invention are as ...

Embodiment 2

[0033] A PP / PA-6 polymer alloy resin for spinning, its formula is as follows by weight percentage, PP molecular chain and maleic anhydride molecular graft polymer: 1.2%, initiator: 0.035%, polypropylene PP resin : 78% and nylon PA-6 resin: 20.765%. The PP molecular chain and maleic anhydride molecular graft polymer is the reactant of maleic anhydride and polyether diol, put the polyether diol and 2 times the molar amount of maleic anhydride into the container, stir, and heat up to 55-60°C, until the maleic anhydride is completely dissolved, gradually raise the temperature to 110°C, when the reaction time reaches 3 hours, the reaction ends, and the reactant of maleic anhydride and polyether glycol is obtained. Described initiator is benzoyl peroxide. The polypropylene PP resin is an isotactic polypropylene PP resin. The melting point of the nylon PA-6 resin is 215-218°C. The polyether diol is dihydroxy-terminated polypropylene with an average molecular weight of 200. A kind...

Embodiment 3

[0035] A PP / PA-6 polymer alloy resin for spinning, its formula is as follows by weight percentage, PP molecular chain and maleic anhydride molecular graft polymer: 1.2%, initiator: 0.06%, polypropylene PP resin : 73.74% and nylon PA-6 resin: 25%. The PP molecular chain and maleic anhydride molecular graft polymer is the reactant of maleic anhydride and polyether diol, put the polyether diol and 2 times the molar amount of maleic anhydride into the container, stir, and heat up to 55-60°C, until the maleic anhydride is completely dissolved, gradually raise the temperature to 110°C, when the reaction time reaches 3 hours, the reaction ends, and the reactant of maleic anhydride and polyether glycol is obtained. Described initiator is benzoyl peroxide. The polypropylene PP resin is an isotactic polypropylene PP resin. The melting point of the nylon PA-6 resin is 215-218°C. The polyether diol is dihydroxy-terminated polypropylene with an average molecular weight of 200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com