Reinforced flame-retardant bamboo-plastic composite material and preparation method thereof

A composite material, bamboo-plastic technology, applied in the field of composite material science, can solve problems such as lack of flame retardancy, limited product application range, and influence on physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the present invention, examples are given in detail.

[0013] Crush the bamboo into 50-200 mesh bamboo powder, then soak it in a sodium hydroxide solution with a mass concentration of 2%-8% for 3-5 hours, take it out and wash it with clean water until it is neutral, then put it in a dryer to dry 60-70 ℃, 3 hours, make its moisture content < 2%, make the pretreated bamboo powder stand-by;

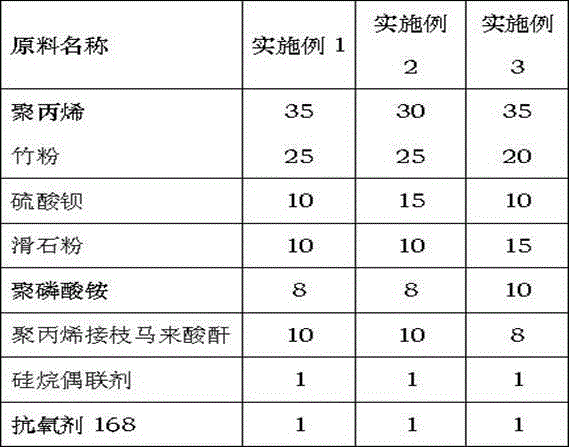

[0014] Add bamboo powder, barium sulfate, talcum powder, ammonium polyphosphate, polypropylene grafted maleic anhydride, silane coupling agent, and antioxidant 168 in a high-speed mixer at 400-600 rpm according to the ratio specified in Table 1. After stirring at a high speed for 30 minutes, add polypropylene and mix and stir for 30 minutes, take it out, dry for 3-4 hours, the drying temperature is 60°C, extrude, pull, cool, and pelletize through a twin-screw extruder , air-dried to prepare a kind of reinforced flame-retardant bamboo-plastic composite ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com