Vinyl silicone oil and synthetic method thereof

A technology of vinyl silicone oil and synthesis method, applied in the field of silicone oil and its synthesis, can solve the problems of high cost, low product yield and the like, and achieve the effects of low cost, high product yield and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The synthetic method of above-mentioned vinyl silicone oil comprises the following steps:

[0027] a, the synthesis of basic catalyst

[0028] Mix octamethylcyclotetrasiloxane and alkali metal hydroxide in a mass ratio of 1-10:1, polymerize at 40-80°C for 2-8 hours, then raise the temperature to 150-180°C, in N 2 Remove oligomers under protection for 3-6 hours to obtain the basic catalyst, preferably polymerize at 50-70°C for 3-4 hours, then raise the temperature to 150-170°C, remove low polymer for 3-5 hours, wherein the alkali metal hydroxide may be potassium hydroxide or sodium hydroxide. The degree of polymerization of the basic catalyst is 10-70.

[0029] b. Synthesis of vinyl silicone oil

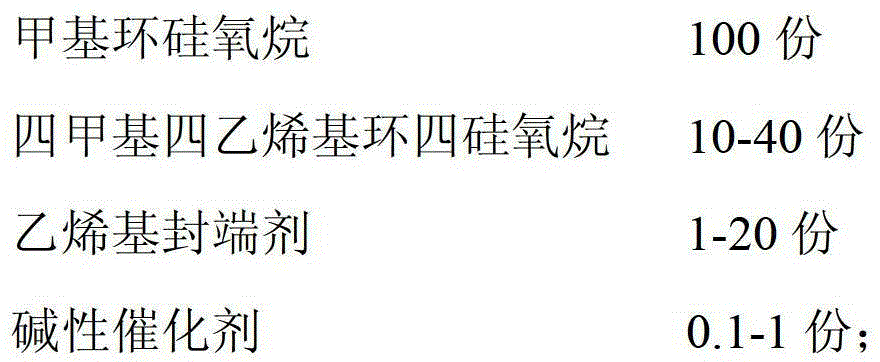

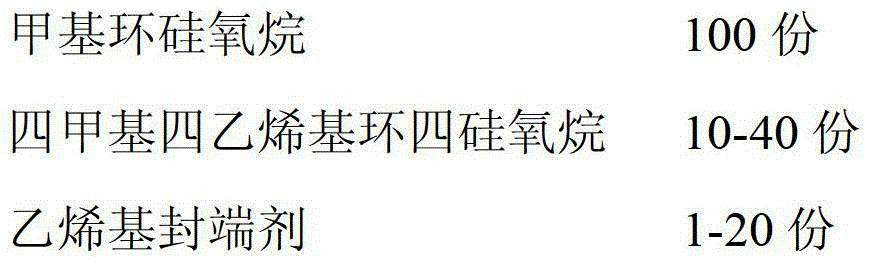

[0030] Step 1. In parts by weight, 100 parts of methylcyclosiloxane and 10-40 parts of tetramethyltetravinylcyclotetrasiloxane are used as reaction monomers, and 1-20 parts of vinyl end-capping agent are added, 0.1 - 1 part of basic catalyst, polymerized at 90-150°C for 2-6...

Embodiment 1

[0034] (1) Synthesis of basic catalyst

[0035] Put 100g of octamethylcyclotetrasiloxane and 25g of potassium hydroxide in a three-necked flask, polymerize at 40°C for 3 hours, then raise the temperature to 150°C, under N 2 The oligomer was removed under protection for 4 hours to obtain the basic catalyst.

[0036] (2) Synthesis of vinyl silicone oil

[0037] Step 1. Take 100g octamethylcyclotetrasiloxane and 15g tetramethyltetravinylcyclotetrasiloxane as reaction monomers, and add 4g dimethylvinylethoxysilane, 0.5g of the base synthesized above catalyst, polymerized at 100°C for 3 hours;

[0038] Step 2. After the polymerization reaction is completed, cool to room temperature, add 10wt% dilute hydrochloric acid to neutralize, adjust pH = 7, wash with water three times, and after separation, remove the low boilers from the obtained polymerization solution at 160°C for 4 hours. Vinyl silicone oil can be obtained.

[0039] The vinyl silicone oil synthesized in this example h...

Embodiment 2

[0041] (1) Synthesis of basic catalyst

[0042] Put 100g of octamethylcyclotetrasiloxane and 40g of potassium hydroxide in a three-necked flask, polymerize at 60°C for 3 hours, then raise the temperature to 170°C, 2 The oligomer was removed under protection for 4 hours to obtain the alkali gel catalyst.

[0043] (2) Synthesis of vinyl silicone oil

[0044] Step 1. Take 50g of octamethylcyclotetrasiloxane, 50g of dodecamethylcyclohexasiloxane and 30g of tetramethyltetravinylcyclotetrasiloxane as reaction monomers, and add 7g of dimethylvinyl Ethoxysilane, 1g of the basic catalyst synthesized above, polymerized at 100°C for 3 hours;

[0045] Step 2. After the polymerization reaction is completed, cool to room temperature, add 10wt% dilute hydrochloric acid to neutralize, adjust pH = 7, wash with water three times, and after separation, remove the low boilers from the obtained polymerization solution at 160°C for 4 hours. Vinyl silicone oil can be obtained.

[0046] The vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com