Preparation method of crack-free coating fiber

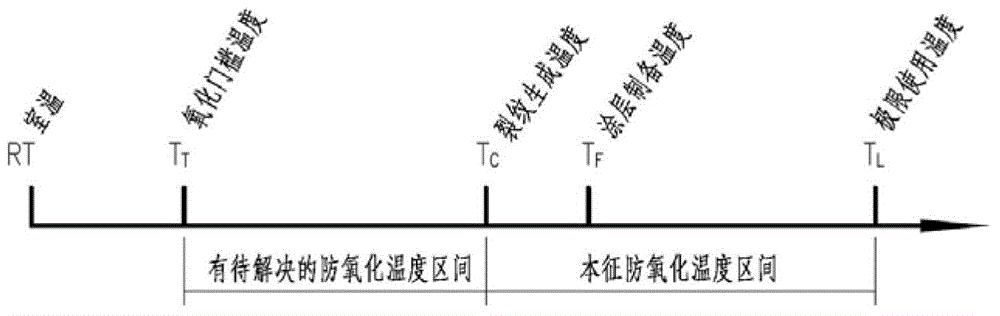

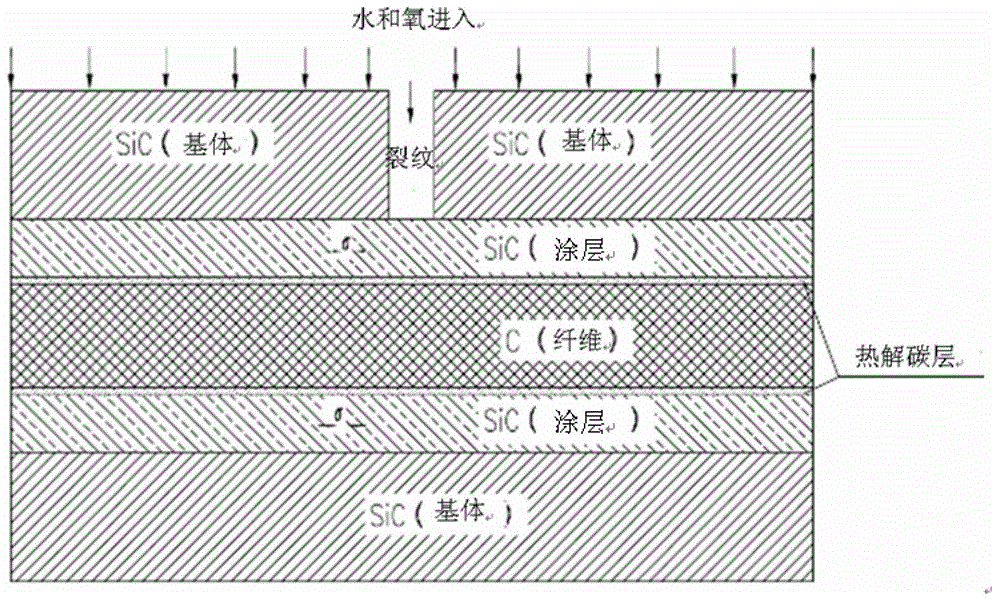

A coated fiber, crack-free technology, applied in the field of preparation of crack-free coated fiber, can solve the problems of many cracks, cracking of coating or substrate, cracking of coating and substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

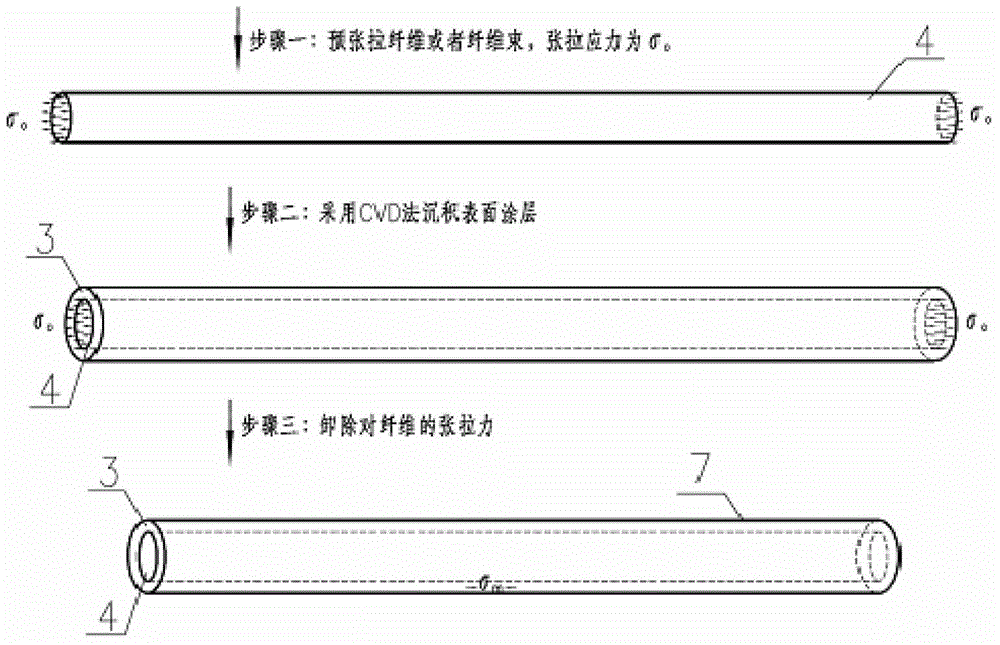

[0114] In this example, T300 carbon fiber (12), SiC coating (3), the relevant characteristics of SiC coating (3) and T300 carbon fiber (12) are shown in Table 1; no crack coating fiber was prepared, and the gravity loading device (9) Using gravity loading, the method is as follows:

[0115] Step 1, depositing a weak interface layer. First degumming at 600 °C, and then uniformly depositing a 0.3 μm pyrolytic carbon PyC interface layer on T300 carbon fiber (12), the deposition device uses such as Figure 13 In the device shown, the raw material is high-purity acetylene gas, and the protective gas is Ar gas. During the CVD deposition process, since the thickness of the interface layer is very thin, tension can be applied to the T300 carbon fiber (12), and the pyrolytic carbon layer can also be deposited without tension, which has little influence on the force of the anti-oxidation coating.

[0116] Step 2, under the action of tension, uniformly deposit the anti-oxidation coatin...

Embodiment 2

[0126] This embodiment adopts carbon fiber (12), B 4 C coating (3), preparation of crack-free coated fibers, B 4 The relevant characteristics of C coating and C fiber are shown in Table 3. The gravity loading device (9) adopts gravity loading, and the CVD deposition device such as Figure 14 ,Methods as below:

[0127] Step 1, depositing a weak interface layer. First, degumming is performed at a temperature of 600°C in the degumming furnace 30, and a 0.3 μm pyrolytic carbon PyC interface layer is evenly deposited on the carbon fiber (12). The deposition device adopts such as Figure 14 For the pyrolytic carbon high-temperature deposition furnace (31) shown, the raw material is high-purity acetylene gas, and the protective gas is high-purity N 2 . During CVD deposition, a layer of pyrolytic carbon may be deposited by applying tension to the carbon fibers (12).

[0128] Step 2, under the action of tension, uniformly deposit the anti-oxidation coating. The anti-oxidation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com