Anti-cracking waterproof mortar

A waterproof mortar and mortar technology, applied in the field of building materials, can solve problems such as low bond strength performance, and achieve the effects of good waterproofness, reasonable ratio, high bond strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

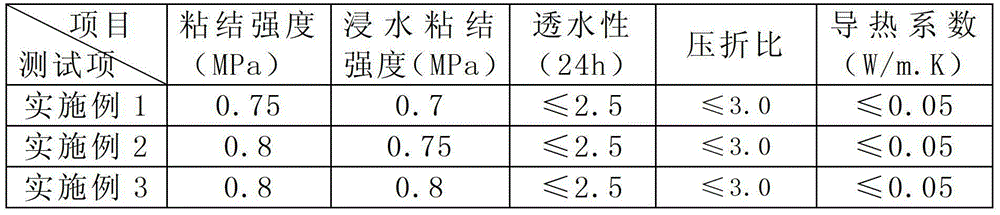

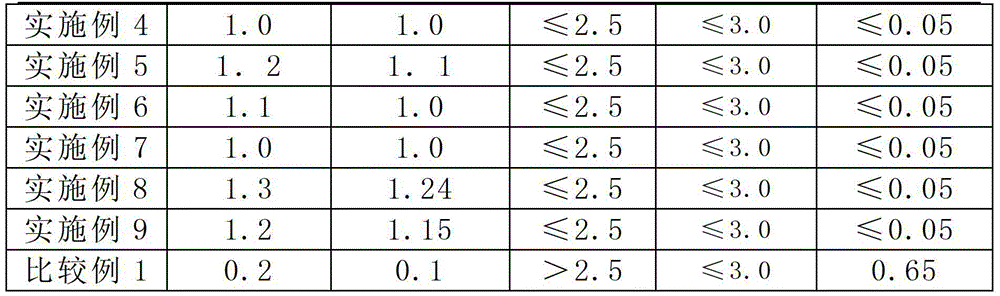

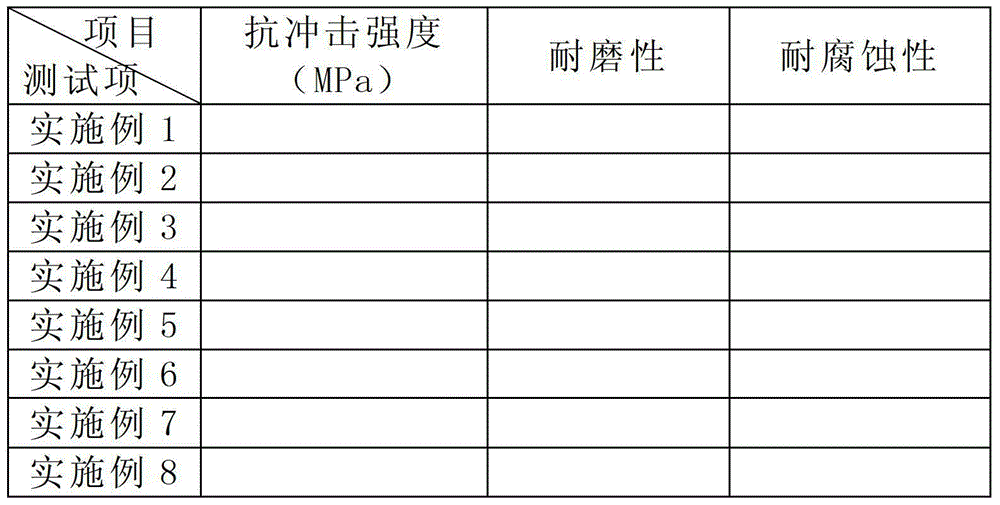

Examples

Embodiment 1

[0028] Anti-cracking waterproof mortar, including the mass percentage of the following components:

[0029] Cement: 27wt%, said cement is Portland cement;

[0030] Sand: 70wt%;

[0031] Polymer latex powder: 2.5wt%, said polymer latex powder is selected from vinyl acetate-ethylene copolymer powder;

[0032] Admixture: 0.5wt%, the admixture is a mixture of starch ether, wood fiber and polypropylene fiber, and the mass ratio of starch ether: wood fiber: polypropylene fiber is 1:0.2:0.5;

[0033] Fatty acid water repellent: 0.2wt%.

[0034] After weighing the corresponding raw materials according to the mass percentage of the above-mentioned components and mixing them uniformly, adding an appropriate amount of water, stirring and mixing them uniformly, the slurry-resistant and waterproof mortar is obtained.

Embodiment 2

[0036] Anti-cracking waterproof mortar, including the mass percentage of the following components:

[0037] Cement: 35wt%, said cement is Portland cement;

[0038] Sand: 62wt%;

[0039] Polymer latex powder: 2.0wt%, said polymer latex powder is selected from vinyl acetate, ethylene and higher fatty acid ethylene fat ternary copolymer rubber powder;

[0040] Admixture: 0.8wt%, the admixture is a mixture of starch ether, wood fiber and polypropylene fiber, and the mass ratio of starch ether: wood fiber: polypropylene fiber is 1:0.4:0.4;

[0041] Fatty acid water repellent: 0.2wt%.

[0042] After weighing the corresponding raw materials according to the mass percentage of the above-mentioned components and mixing them uniformly, adding an appropriate amount of water, stirring and mixing them uniformly, the slurry-resistant and waterproof mortar is obtained.

Embodiment 3

[0044] Anti-cracking waterproof mortar, including the mass percentage of the following components:

[0045] Cement: 34wt%, said cement is Portland cement;

[0046] Sand: 64wt%;

[0047] Polymer latex powder: 2.2wt%, said polymer latex powder is selected from vinyl acetate and higher fatty acid vinyl fat copolymerized rubber powder;

[0048] Admixture: 0.7wt%, the admixture is a mixture of starch ether, wood fiber and polypropylene fiber, and the mass ratio of starch ether: wood fiber: polypropylene fiber is 1:0.35:0.45;

[0049] Fatty acid water repellent: 0.1wt%.

[0050] After weighing the corresponding raw materials according to the mass percentage of the above-mentioned components and mixing them uniformly, adding an appropriate amount of water, stirring and mixing them uniformly, the slurry-resistant and waterproof mortar is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com