Loading and unloading manipulator system of broaching machine

A technology of manipulators and upper waist seats, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve problems such as low production efficiency and high labor intensity, and achieve the effects of increased efficiency, fast and accurate transposition, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

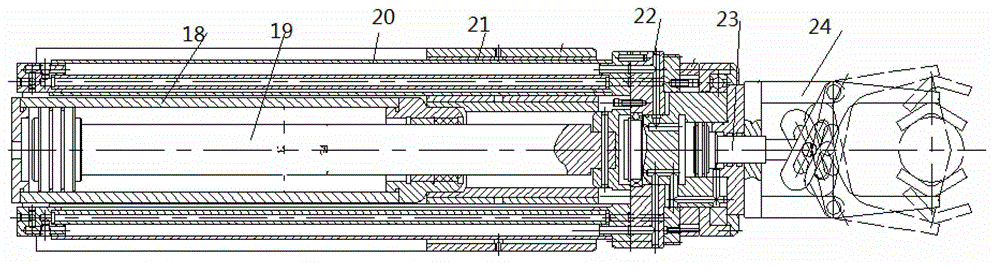

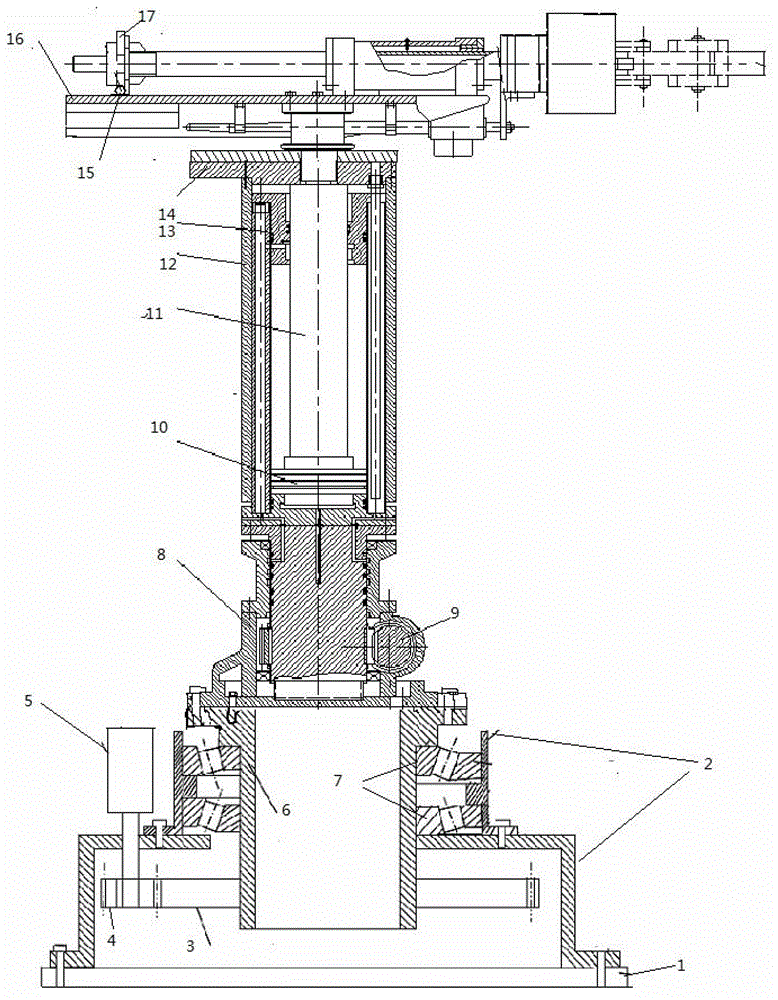

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

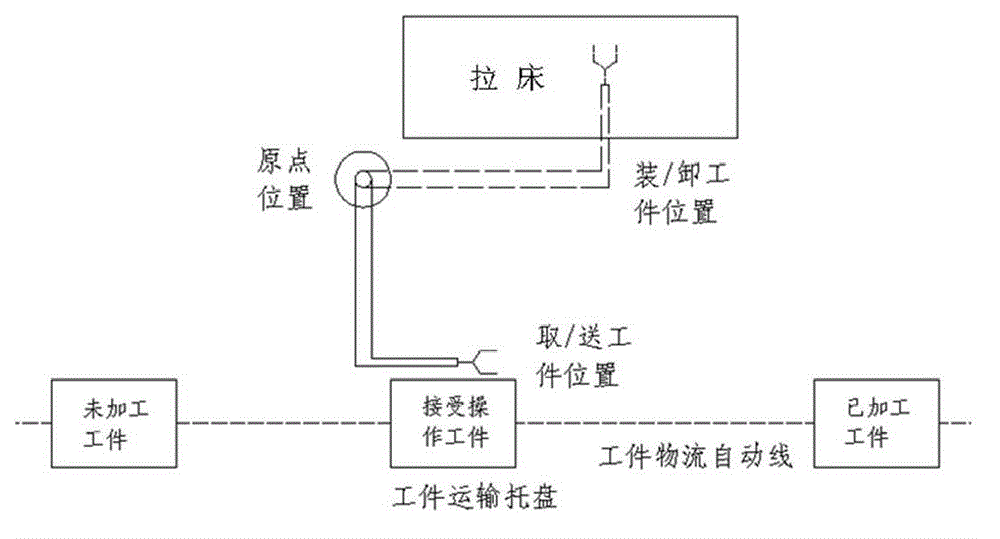

[0025] Such as figure 1 , figure 2 , Figure 4 As shown, a broaching machine loading and unloading manipulator system, the object of the present invention is to provide a broaching machine loading and unloading manipulator system for the deficiencies of the prior art.

[0026] The present invention includes an executive mechanism, a driving mechanism and a hydraulic control mechanism, and the driving mechanism includes a waist seat 2, a large gear 3, a pinion 4, a stepping motor 5, a waist rotary shaft 6, a tapered roller bearing 7, a fixed column 8, and a rack Cylinder 9;

[0027] The waist seat 2 includes an upper waist seat and a lower waist seat. The upper waist seat is a cylindrical shape with open ends, and an annular protrusion is provided on the inner surface. Two tapered roller bearings 7 are arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com