Preparation method for tomato powder

A technology for tomato powder and tomato, applied in the field of food processing, can solve the problems of high investment and operation cost of supporting facilities for continuous production and processing of tomato powder, and the inability to realize tomato powder, so as to reduce drying energy consumption, low drying energy consumption, industrial promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 prepares tomato powder with fresh tomato

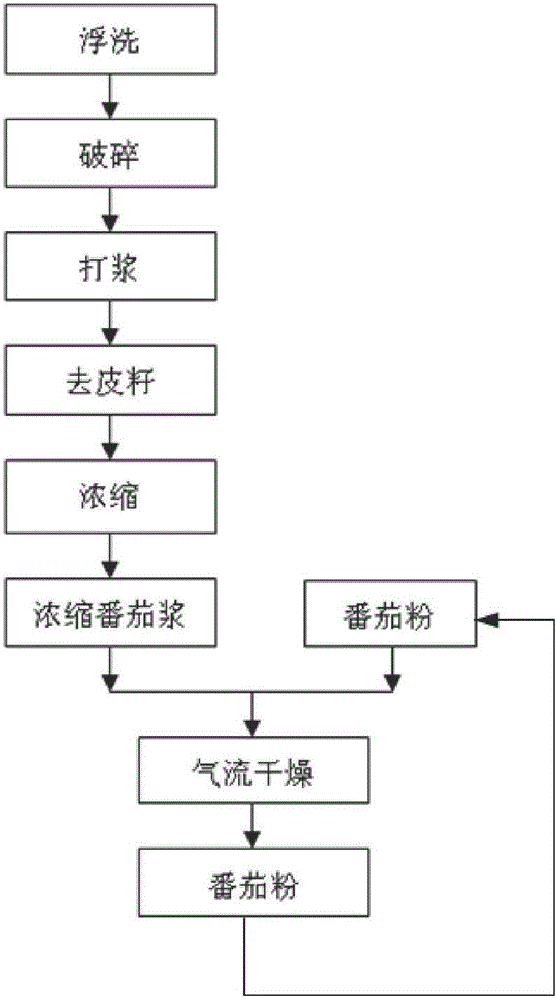

[0023] according to figure 1 The flow shown proceeds through the following steps.

[0024] 1) Fresh tomatoes are float washed, crushed, beaten, peeled and seeded, and concentrated to make tomato pulp, that is, water-containing tomato raw materials, and its water content is 72% by weight;

[0025] 2) Add tomato powder to the tomato pulp obtained in the above step 1) to prepare a tomato raw material mixture, reducing the moisture content of the tomato raw material mixture to 25-45% by weight; when performing step 1) for the first time, the tomato powder used can be Purchased tomato powder or previously prepared tomato powder, or tomato powder obtained by other means; after obtaining tomato powder in step 4), the tomato powder for this step is obtained from step 4).

[0026] 3) Fully mix the tomato raw material mixture obtained in the above step 2) evenly;

[0027] 4) Dry the homogeneously mixed tomato raw material...

Embodiment 2

[0029] Embodiment 2 prepares tomato powder with tomato paste

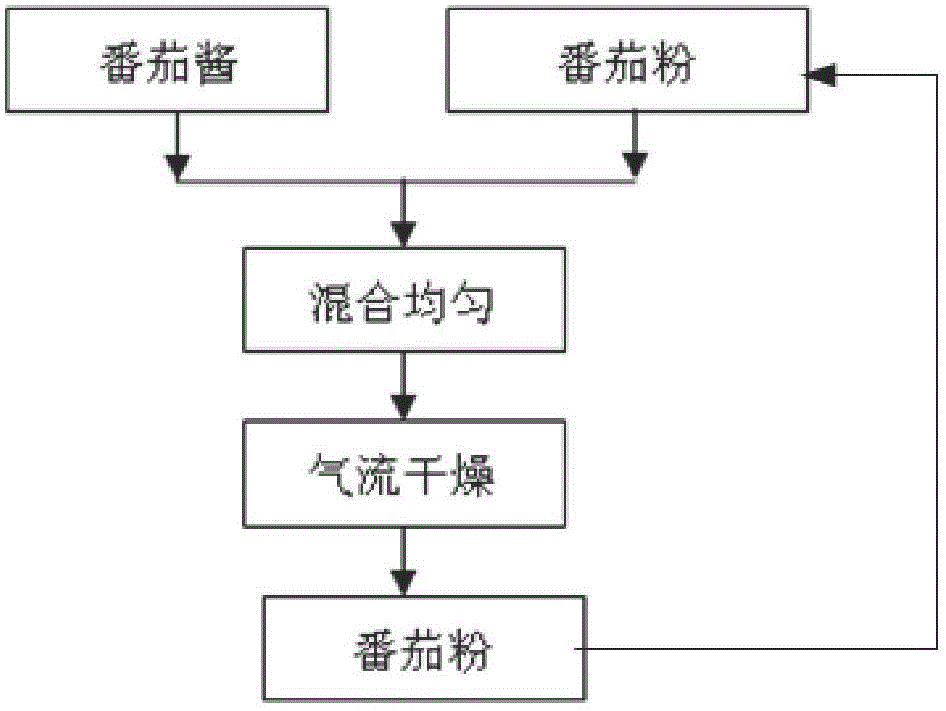

[0030] according to figure 2 The flow shown proceeds through the following steps.

[0031] 1) Add tomato powder to tomato paste with a water content of 68% by weight, so that the water content of the tomato raw material mixture composed of tomato paste and tomato powder is reduced to 30-35% by weight; It will cause high viscosity due to low moisture content, which will affect the feeding speed during air drying; it will not increase processing energy consumption due to high moisture content. When performing step 1) for the first time, the tomato powder used can be purchased tomato powder or previously prepared tomato powder, or tomato powder obtained by other means; after obtaining tomato powder in step 3), the tomato powder in this step is obtained from step 3 ) to get tomato powder.

[0032] 2) Fully mix the tomato raw material mixture obtained in the above step 1) evenly;

[0033] 3) Air-dry the homogeneous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com