Tobacco leaf grading method based on reflection, perspective and microscopic images

A microscopic image and grading method technology, which is applied to the analysis of materials, material analysis through optical means, and measurement devices, etc., can solve the problems of poor effect, large amount of calculation by the nearest neighbor algorithm, and a large number of operators, so as to avoid Effects of human interference, reduction of follow-up calculations, and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

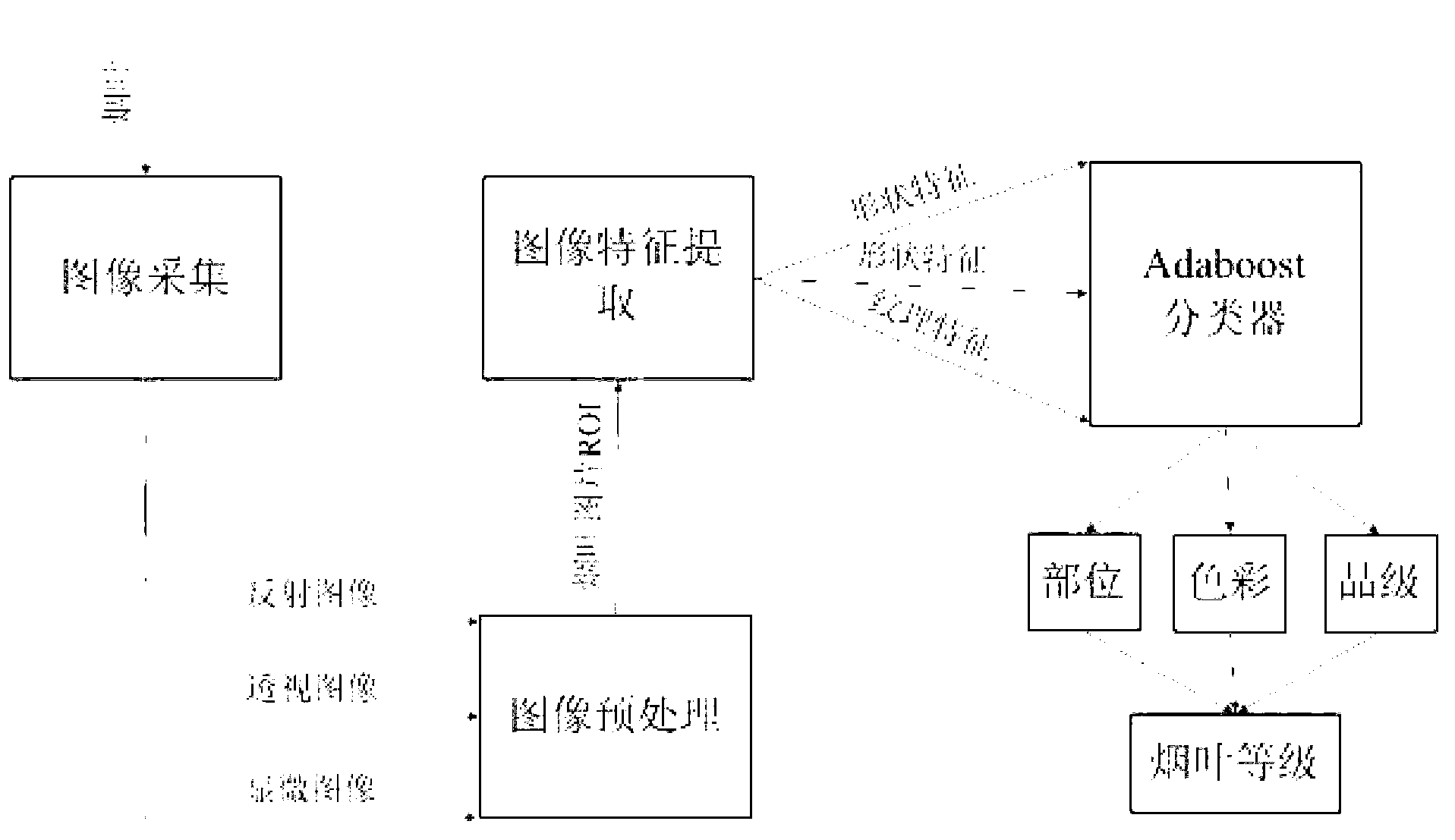

[0035] Example: Tobacco leaf grading method based on reflection, perspective and microscopic images, the process is as follows figure 1 As shown, it specifically includes the following steps:

[0036] (1) Obtain high-definition color reflection images of tobacco leaves in real time.

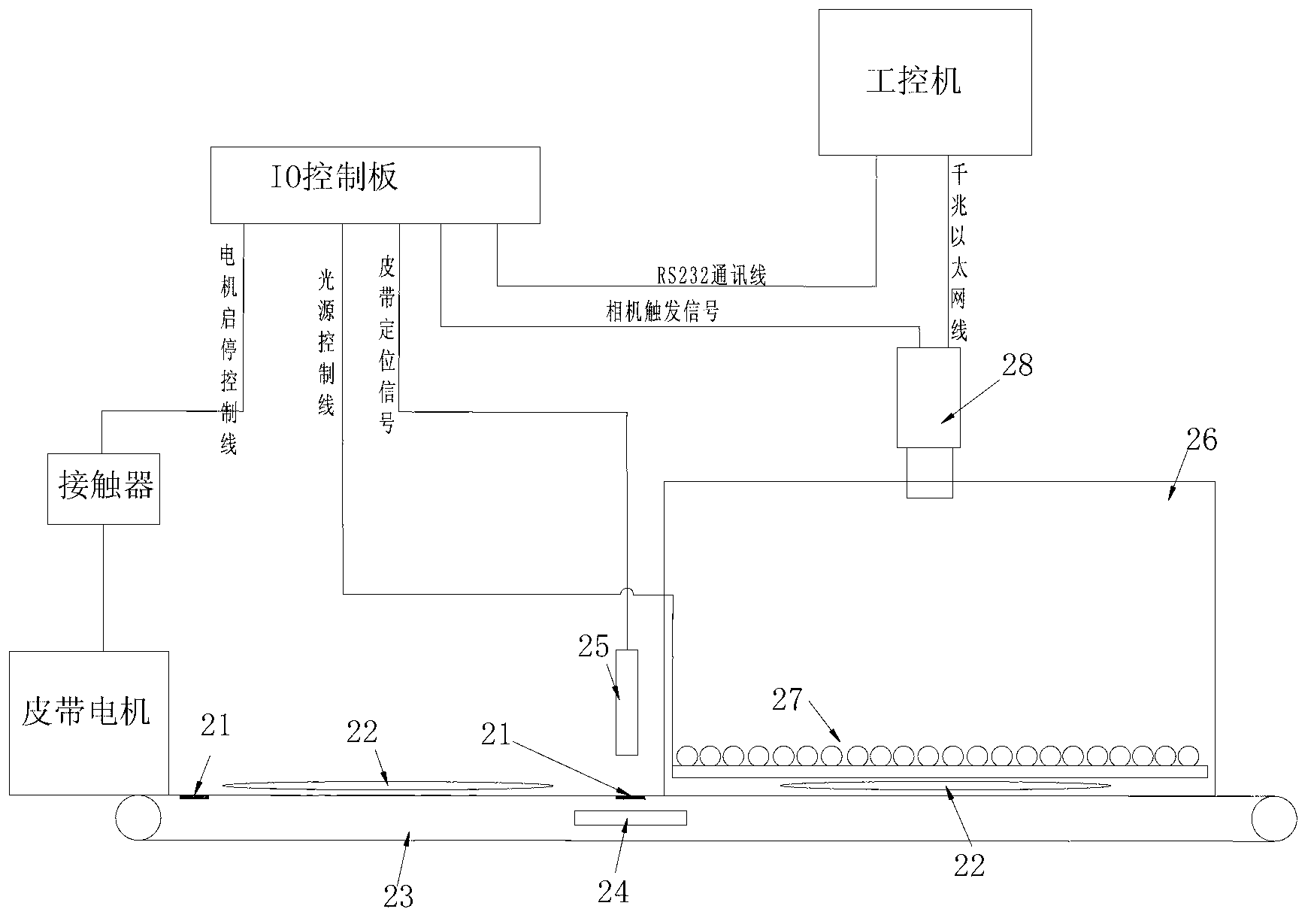

[0037] Such as figure 2 As shown, the industrial computer starts the belt motor through the IO control board, and the tobacco leaves are placed on the belt and transported through the belt. The positioning holes are set on the belt. When the tobacco leaves reach the designated position, that is, inside the reflector, the photocell sends positioning information to the IO control through the positioning holes. board, the IO control board drives the light source and the camera. At this time, the 3CCD high-definition area array color camera shoots the tobacco leaves directly below, and transmits the captured image to the industrial computer through a Gigabit network cable to obtain a high-definit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com