Automatic analyzer

a technology of automatic analysis and analyzer, which is applied in the direction of material analysis, chemical methods analysis, instruments, etc., can solve the problems of inability to perform calibration and precision control, and achieve the effect of easing the burden on the operator and facilitating precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]A configuration and operations of an automatic analysis system according to an embodiment of the present invention will be explained below with reference to FIGS. 1 to 9.

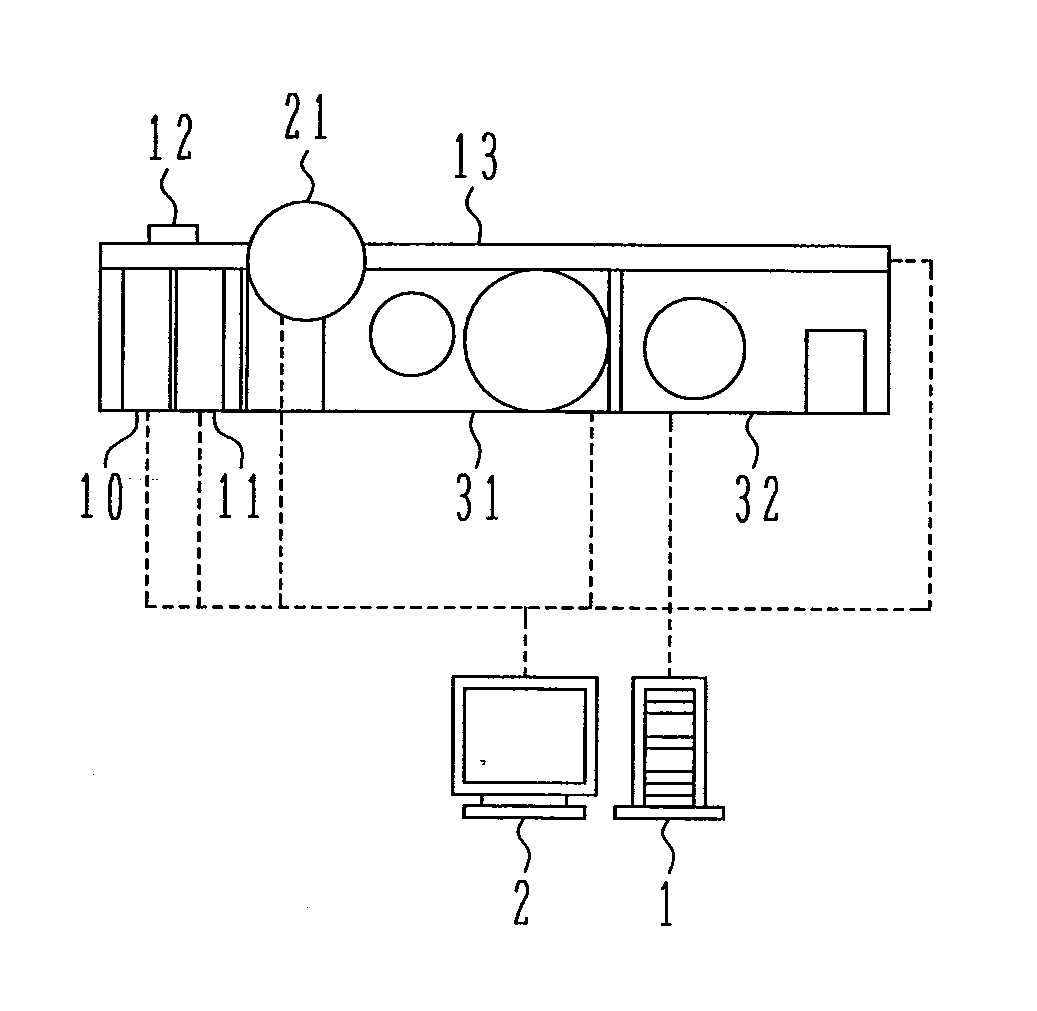

[0028]FIG. 1 is a diagram showing a general configuration of an automatic analyzer according to an embodiment of the present invention.

[0029]The automatic analysis system according to the present embodiment comprises: a sample rack input part 10; a sample rack storage part 11; an ID reader 12; a transfer line 13, a sample rack buffer unit 21; analysis modules 31 and 32; and management computers 1 and 2.

[0030]The sample rack input part 10 is used to input sample racks which holds samples. The analysis modules 31 and 32 are arranged along the transfer line 13 and removably connected to the transfer line 13. There may be any number of analysis modules. The present embodiment includes two analysis modules.

[0031]The transfer line 13 transfers a sample rack from the sample rack input part 10 to the analysis modules ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| time period | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com