Molecular Beam Epitaxy Growth Method of Gaas-Based Nanowires Regulated by Bi Elements

A technology of molecular beam epitaxy and crystal structure, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems affecting the uniformity of photoelectric device performance and unfavorable growth of nanowires with uniform length and thickness, so as to achieve excellent materials and high reliability. The effect of growth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

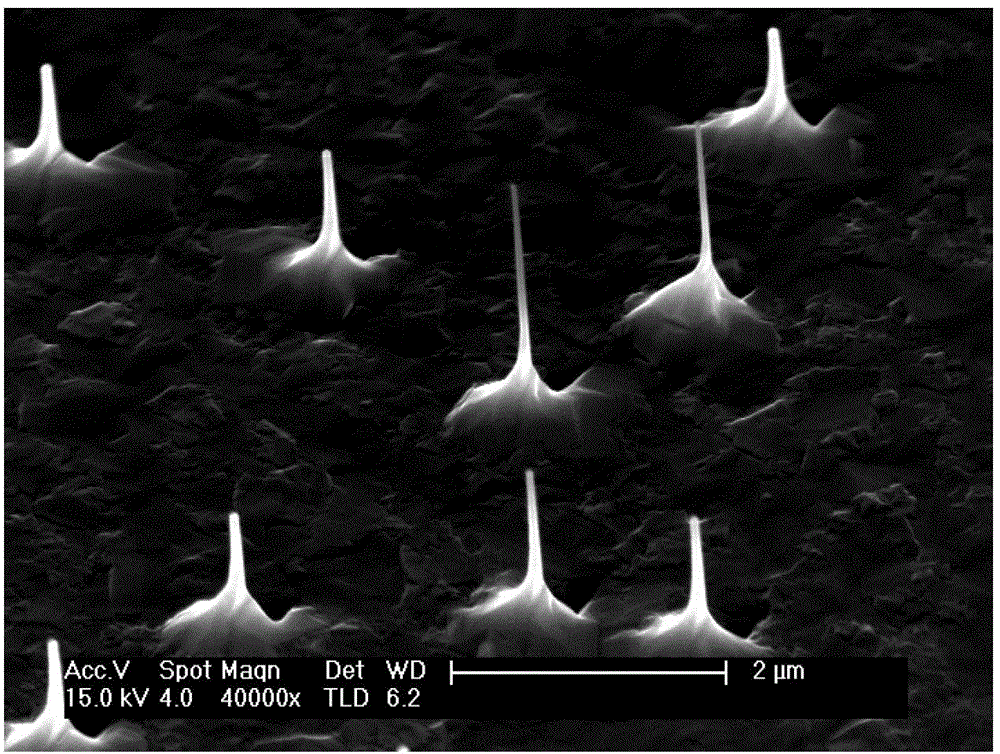

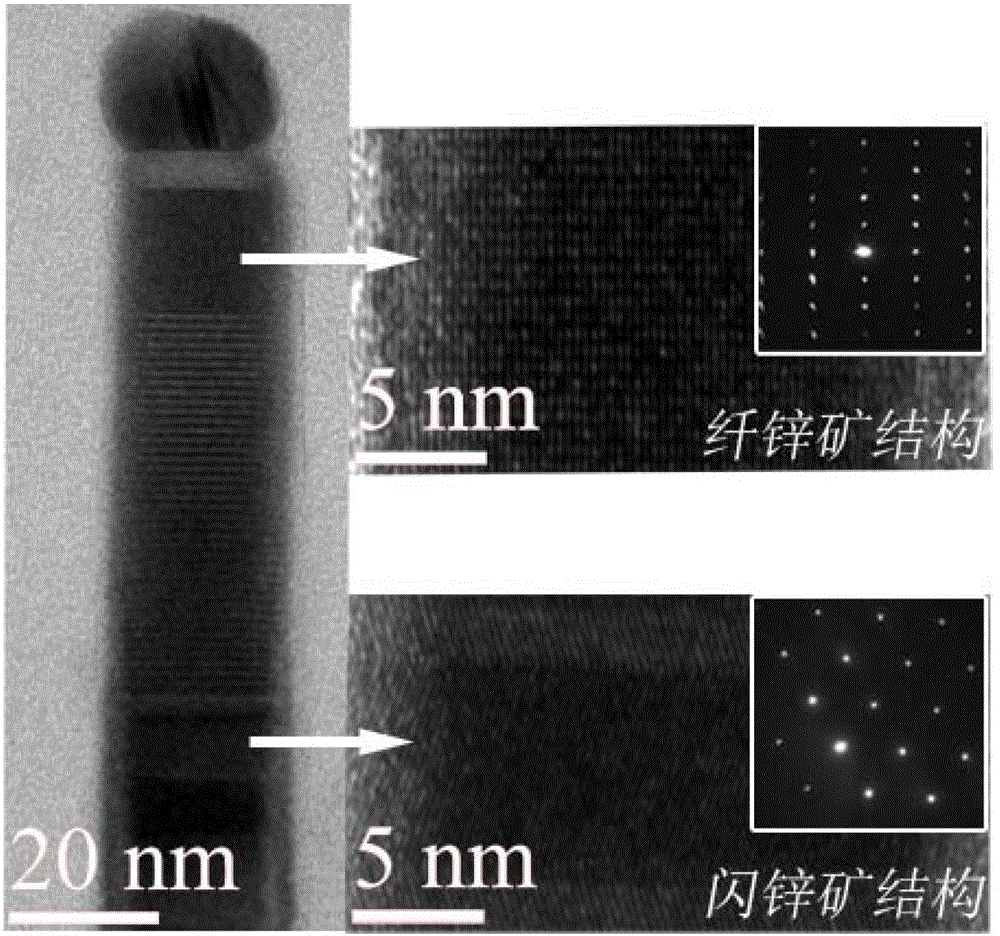

[0017] In this example, the temperature of the storage furnace of the As evaporation source is controlled at 180°C, the temperature of the Ga evaporation source is controlled at 950°C, and the temperature of the Bi evaporation source is controlled at 480°C, so that x=40%. The GaAs(111)B substrate was loaded into the MBE growth chamber, and the growth temperature was controlled at 420°C. After growing GaAs nanowires for 10 minutes, under the condition that the growth conditions remained unchanged, the Bi evaporation source baffle was opened, and Bi element was introduced to reduce the ionic type of GaAs, thereby promoting the formation of zinc blende structure GaAs nanowires, and the growth After cooling the substrate and each evaporation source, the sample is introduced into the MBE pretreatment chamber to take out the GaAs nanowires with coexistence of wurtzite structure and sphalerite structure. High-resolution transmission electron microscopy and selected area electron diff...

Embodiment 2

[0019] In this example, the temperature of the storage furnace of the As evaporation source is controlled at 180°C, the temperature of the Ga evaporation source is controlled at 950°C, and the temperature of the Bi evaporation source is controlled at 500°C, so that x=66%. The GaAs(111)B substrate was loaded into the MBE growth chamber, and the growth temperature was controlled at 420°C. After growing GaAs nanowires for 10 minutes, under the condition that the growth conditions remained unchanged, the Bi evaporation source baffle was opened, and Bi element was introduced to reduce the ionic type of GaAs, thereby promoting the formation of zinc blende structure GaAs nanowires, and the growth After cooling the substrate and each evaporation source, the sample is introduced into the MBE pretreatment chamber to take out the GaAs nanowires with coexistence of wurtzite structure and sphalerite structure. High-resolution transmission electron microscopy and selected area electron diff...

Embodiment 3

[0021] In this example, the temperature of the storage furnace of the As evaporation source is controlled at 180°C, the temperature of the Ga evaporation source is controlled at 940°C, and the temperature of the Bi evaporation source is controlled at 500°C, so that x=50%. The GaAs(111)B substrate was loaded into the MBE growth chamber, and the growth temperature was controlled at 420°C. After growing GaAs nanowires for 10 minutes, under the condition that the growth conditions remained unchanged, the Bi evaporation source baffle was opened, and Bi element was introduced to reduce the ionic type of GaAs, thereby promoting the formation of zinc blende structure GaAs nanowires, and the growth After cooling the substrate and each evaporation source, the sample is introduced into the MBE pretreatment chamber to take out the GaAs nanowires with coexistence of wurtzite structure and sphalerite structure. High-resolution transmission electron microscopy and selected area electron diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com