Nitride fluorescent powder and preparation method thereof, light-emitting device comprising nitride fluorescent powder

A technology of nitride phosphors and phosphors, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems affecting device performance and low relative brightness, and achieve improved luminous efficiency, low cost, and simple preparation methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preferably, the above-mentioned preparation method includes the following steps: firstly, the nitrides of alkaline earth metals, Si and Eu are used as raw materials for primary mixing, and the primary mixture is heated at 1500-1800°C, preferably 1600-1700°C, under nitrogen and / or hydrogen atmosphere Medium roasting for 5-10h, preferably 6-10h, to obtain a roasted product; then use Si oxides and / or Al oxides as raw materials to perform secondary mixing with the roasted product, and place the secondary mixture at 1500-1800°C under nitrogen And / or heat treatment in a hydrogen atmosphere for 0.5-2h, preferably 1-2h, to obtain the required nitride phosphor; wherein the amount of the above-mentioned raw materials is weighed according to the weight percentage of each element in the nitride phosphor of the present invention , wherein the amount of Si nitride, Si oxide, and Al Al oxide is matched so that in the prepared nitride phosphor particles, the range of 0-50nm extending fr...

Embodiment 1

[0052] Preparation:

[0053] Accurately weigh 51.81gSr 3 N 2 , 22.14gAlN, 25.19gSi 3 N 4 and 0.9gEuN, after mixing evenly, roasted at 1600°C for 10h in a mixed atmosphere of nitrogen and hydrogen to obtain a roasted product, lower the temperature to below 100°C, take it out, and crush it to obtain roasted particles with an average particle size of 10μm; The above-mentioned calcined particles were mixed with 0.4g of Al 2 o 3 And mix evenly, in a nitrogen atmosphere, keep warm at 1500°C for 2 hours, then lower the temperature to below 100°C, take it out, crush it to obtain particles with an average particle size of 10 μm, wash with water, dry and pass through a 450-mesh sieve, Obtain required fluorescent powder, the mass ratio of Sr element, Al element, Si element, N element, O element and Eu element in fluorescent powder and phosphor powder mass ratio is respectively: 46.6%, 14.7%, 15.1%, 22.6%, 0.2 % and 0.8%.

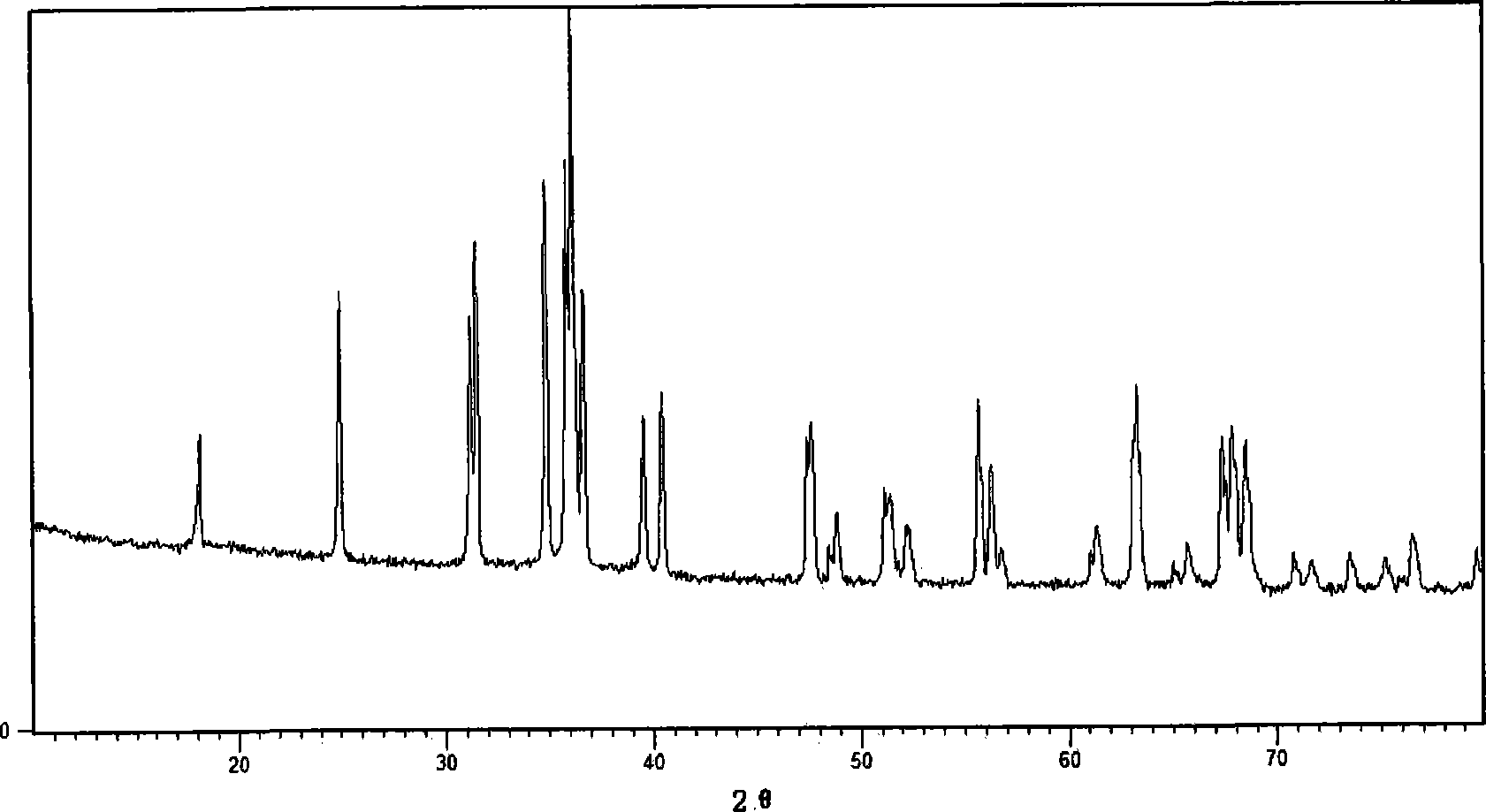

[0054] X-ray diffraction: eg figure 1 As shown, the nitri...

Embodiment 2-4

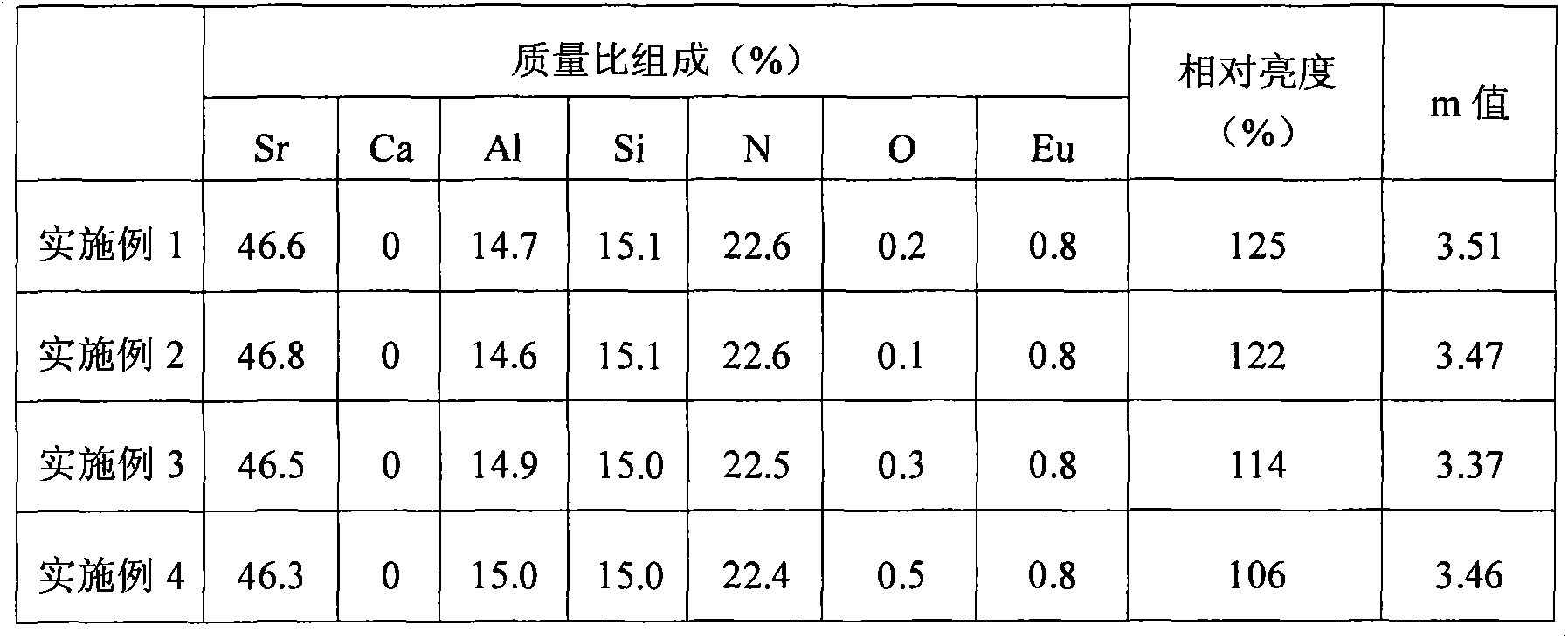

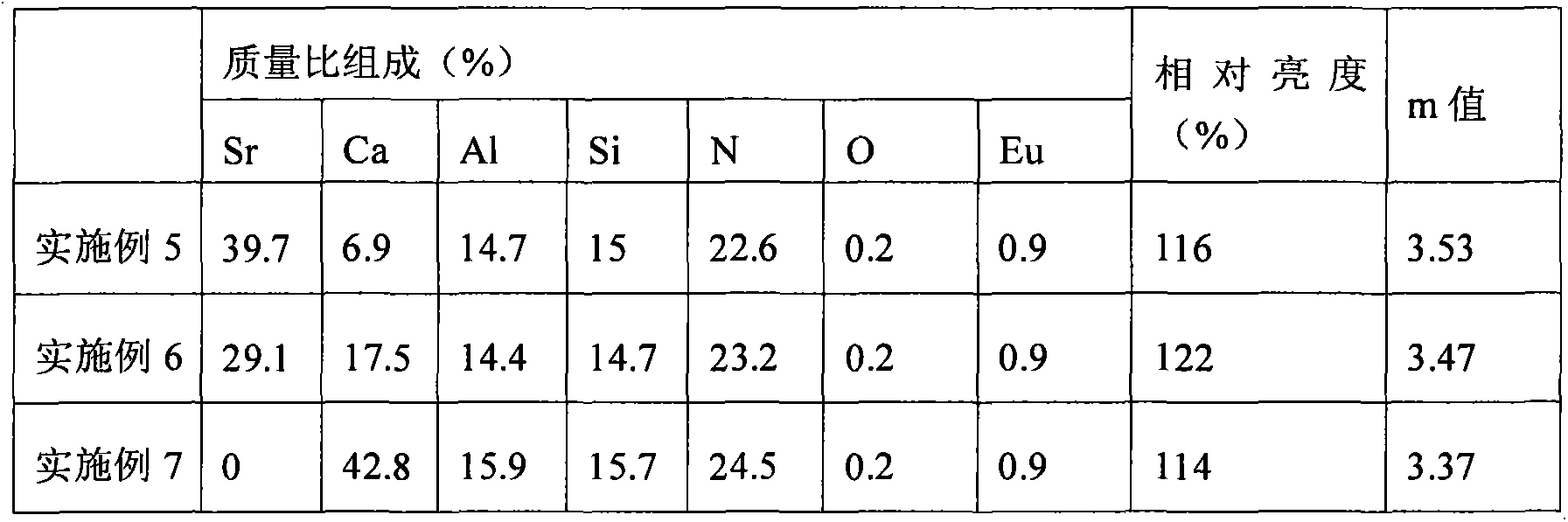

[0058] The phosphor powder preparation process in embodiment 2-4 is basically the same as embodiment 1, only the added Al 2 o 3 The amount is different, the amount added is 0.1g, 0.7g and 1g respectively. The mass ratio and m value of each element in the prepared phosphor are shown in Table 2.

[0059] The mass ratio composition, relative brightness and m value of Table 1 embodiment 1-4 phosphor

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com