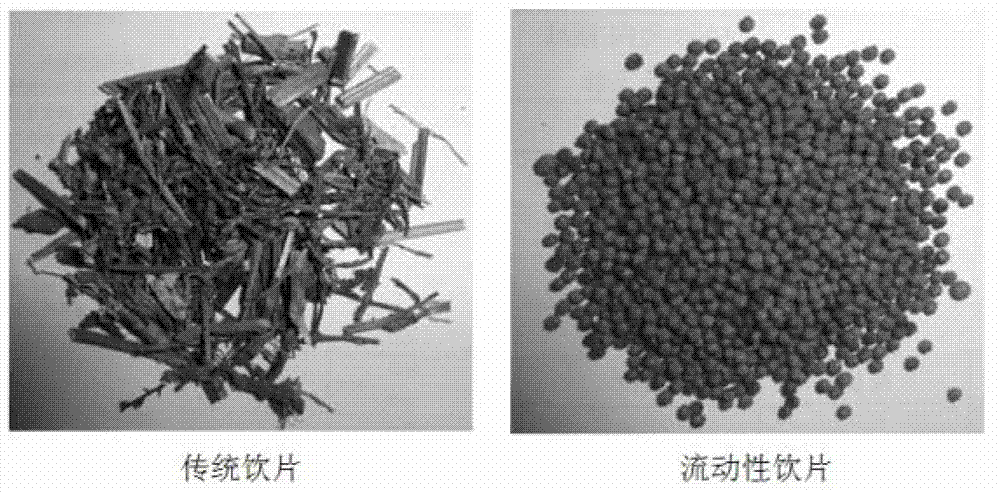

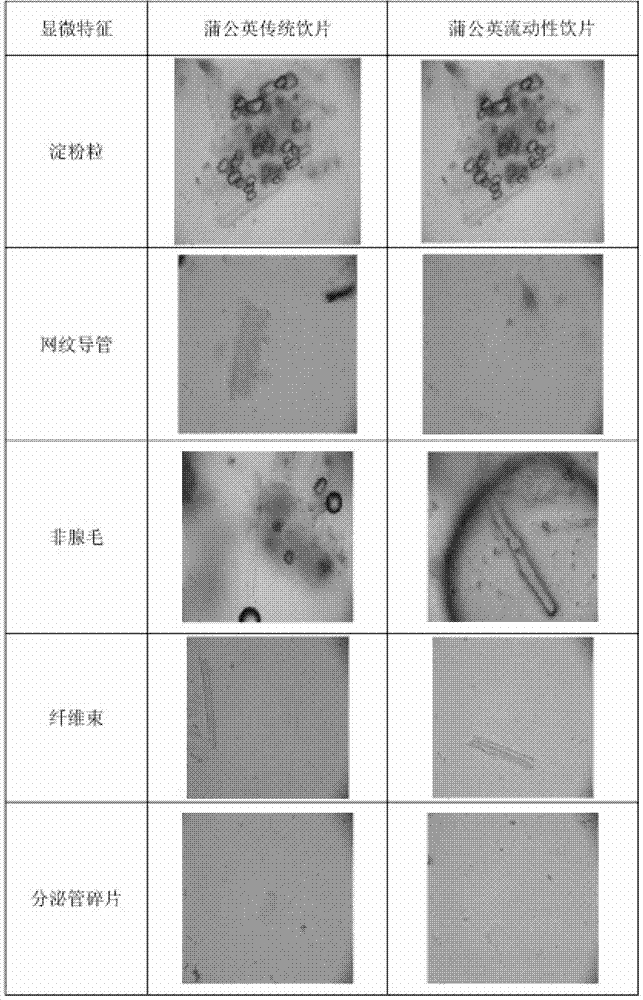

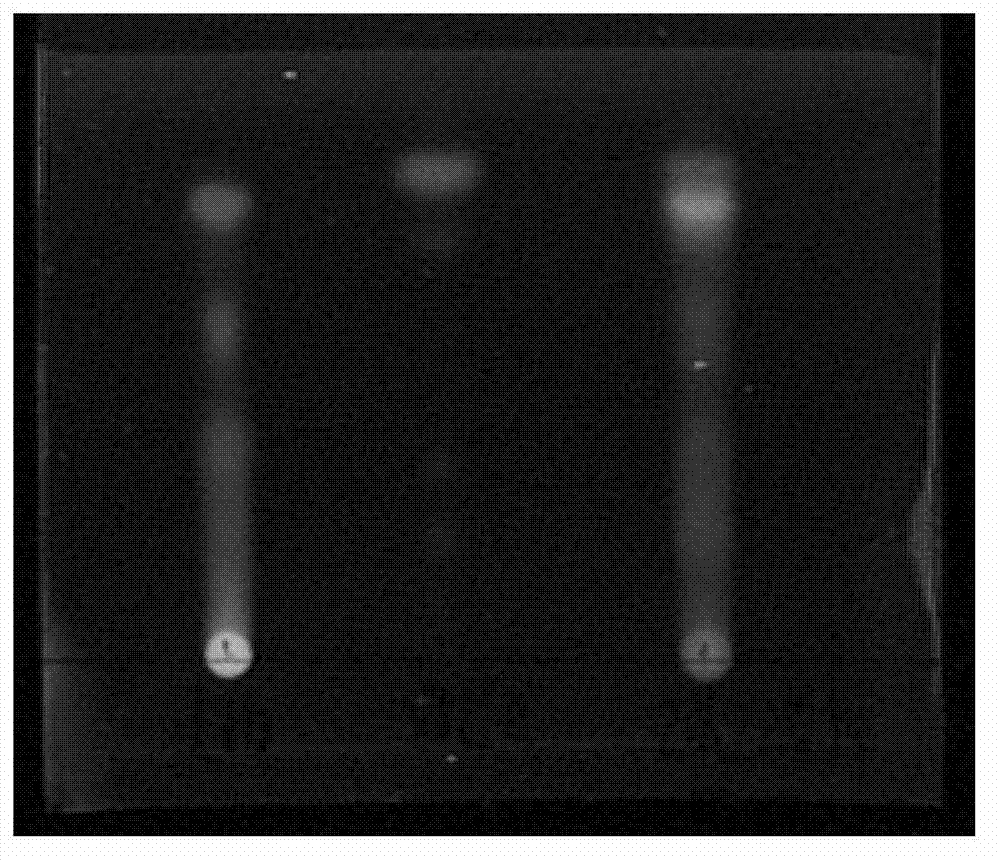

Dandelion fluid decoction pieces and preparation method thereof

A technology of dandelion and fluidity, which is applied in diseases, medical formulas, allergic diseases, etc., can solve the problems of bulky, fluffy, difficult storage and packaging, etc., and achieve the effect of good fluidity, uniform density, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The traditional decoction pieces of dandelion are pulverized and passed through an 80-mesh sieve to obtain medicinal powder. The powder was heated at 95°C for 4 hours.

[0036] Take an appropriate amount of medicine powder (500g) and pour it into a high-efficiency mixing granulator, add water and mix evenly at a weight ratio of 1:1.4, transfer the obtained soft material to a rotary granulator for granulation, and the aperture of the screen is 1.0mm , the wet particles are shot blasted in a centrifugal shot blasting machine (rotating speed 500rpm, time 20min), and the wet shot blasting is put into a blast drying oven, and electric blast drying is performed at 60°C for 8 hours. Take it out and let it cool at room temperature, pass through a sieve, and take a shot shot between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) to obtain fluid decoction pieces of dandelion.

Embodiment 2

[0038] The sorted and selected dandelion is pulverized and passed through a 60-mesh sieve to obtain medicinal powder. The powder was heated at 90°C for 5 hours.

[0039] Take an appropriate amount of medicine powder (500g) and pour it into a high-efficiency mixing granulator, add water and mix evenly at a weight ratio of 1:1.4, transfer the obtained soft material to a rotary granulator for granulation, and the aperture of the screen is 1.0mm , the wet particles are shot blasted in a centrifugal shot blasting machine (rotating speed 520rpm, time 18min), and the wet shot blasting is put into a blast drying oven, and dried by electric blast at 60°C for 8 hours. Take it out and let it cool at room temperature, pass through a sieve, and take a shot shot between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) to obtain fluid decoction pieces of dandelion.

Embodiment 3

[0041] The traditional decoction pieces of dandelion are pulverized and passed through a 100-mesh sieve to obtain medicinal powder. The powder was heat-treated at 100°C for 4 hours.

[0042] Take an appropriate amount of medicine powder (500g) and pour it into a high-efficiency mixing granulator, add water and mix evenly at a weight ratio of 1:1.6, transfer the obtained soft material to a rotary granulator for granulation, and the aperture of the screen is 1.0mm , The wet particles are shot blasted in a centrifugal shot blasting machine (rotating speed 480rpm, time 22min), and the wet shot blasting is put into a blast drying oven, and dried at a temperature of 55°C. Take it out and let it cool at room temperature, pass through a sieve, and take a shot shot between No. 1 sieve and No. 2 sieve (that is, 10-24 mesh) to obtain fluid decoction pieces of dandelion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com