Electromagnetic heating circuit utilizing single-chip microcomputer to automatically track resonant frequency

A technology of automatic tracking and resonant frequency, applied in the direction of induction heating, induction heating control, etc., can solve the problems that the resonant frequency cannot be automatically tracked, the resonant frequency tracking range is small, and the IGBT power tube is damaged, and the circuit is simple, low cost, The effect of improving the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

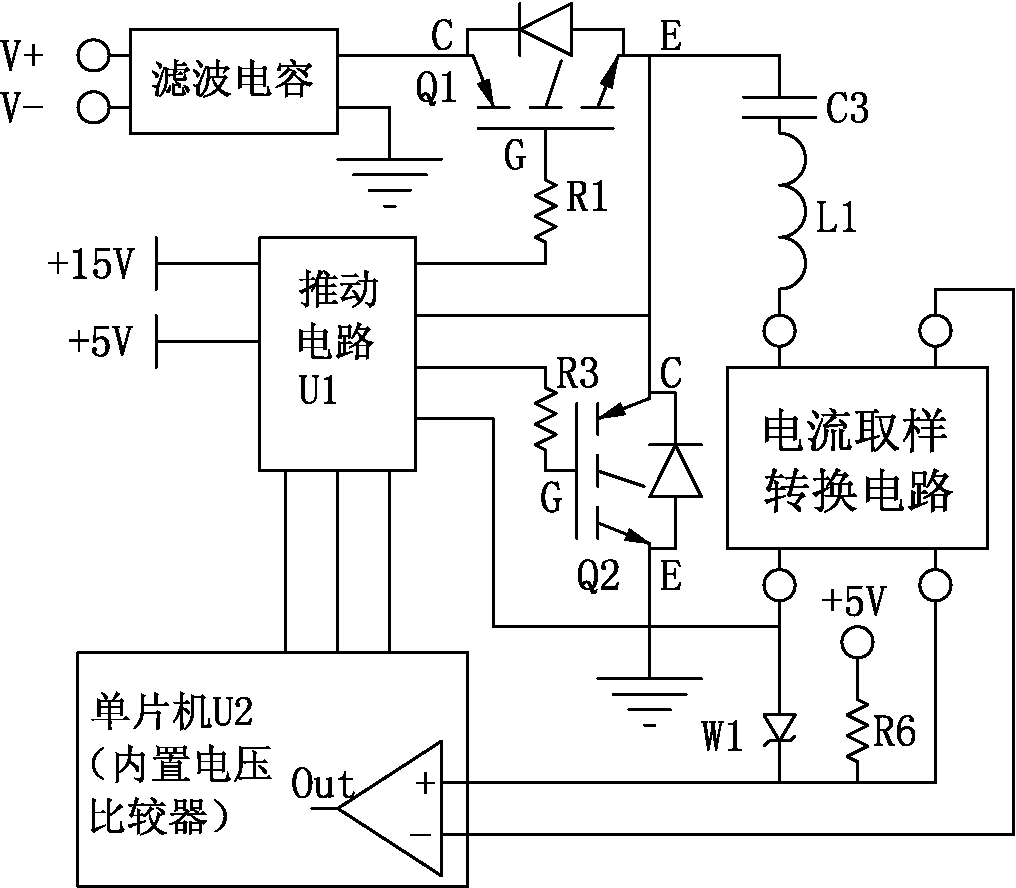

[0012] Such as figure 1 , figure 2 An electromagnetic heating circuit that uses a single-chip microcomputer to automatically track the resonant frequency shown includes a filter capacitor C1, a resonant capacitor C3, an excitation coil L1 and a single-chip control circuit U2, and a push-pull type is connected between the filter capacitor C1 and the resonant capacitor C3. A power switch circuit, a current sampling conversion circuit is connected between the excitation coil L1 and the single-chip microcomputer control circuit U2, a push circuit U1 is connected between the single-chip microcomputer control circuit U2 and the push-pull power switch circuit, and the push-pull power The switch circuit includes IGBT one Q1 and IGBT two Q2, and the IGBT one Q1 and IGBT two Q2 both contain damping diodes, respectively have a collector C, an emitter E and a gate G, and the single-chip control circuit U2 has a built-in voltage comparator , the current sampling conversion circuit includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com