Thin film transistor, preparation method for same and array substrate

A thin-film transistor and array substrate technology, applied in the display field, can solve the problem that the TFT on-state current cannot be too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

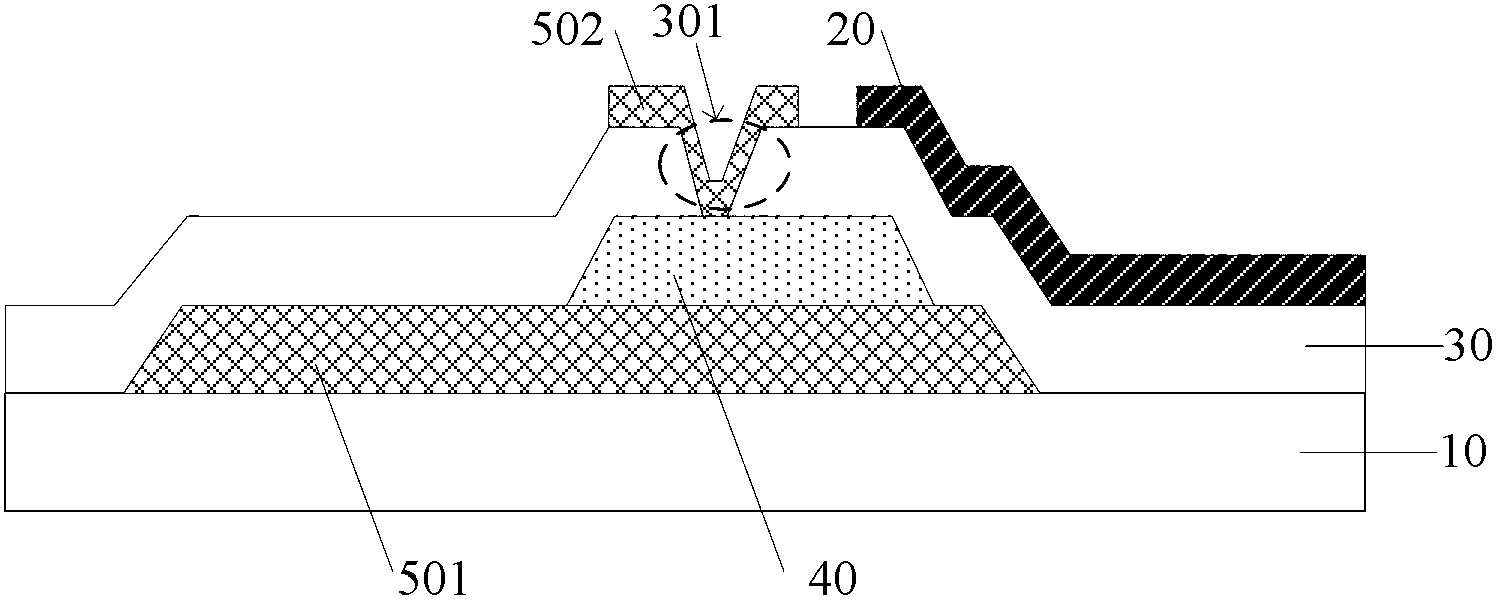

[0055] Embodiment 1 provides a thin film transistor, such as Figure 4 As shown, the thin film transistor includes: a source 501 disposed on the base substrate 10, an active layer 40 disposed above the source, a drain 502 disposed above the active layer, and a drain 502 disposed above the source There is a gate insulating layer 30 between the active layer and the drain, and a gate 20 disposed above the gate insulating layer.

[0056] Wherein, the active layer 40 includes an amorphous silicon semiconductor layer 401 in the middle, a first ohmic contact layer 402 above the amorphous silicon semiconductor layer, and a second ohmic contact layer below the amorphous silicon semiconductor layer. Layer 403.

[0057] The source 501 is in contact with the second ohmic contact layer 403 of the active layer 40, the drain 502 is in the same layer as the gate 20 but not connected, and the drain 502 is arranged on the gate The first via hole 301 on the insulating layer 30 is in contact wi...

Embodiment 2

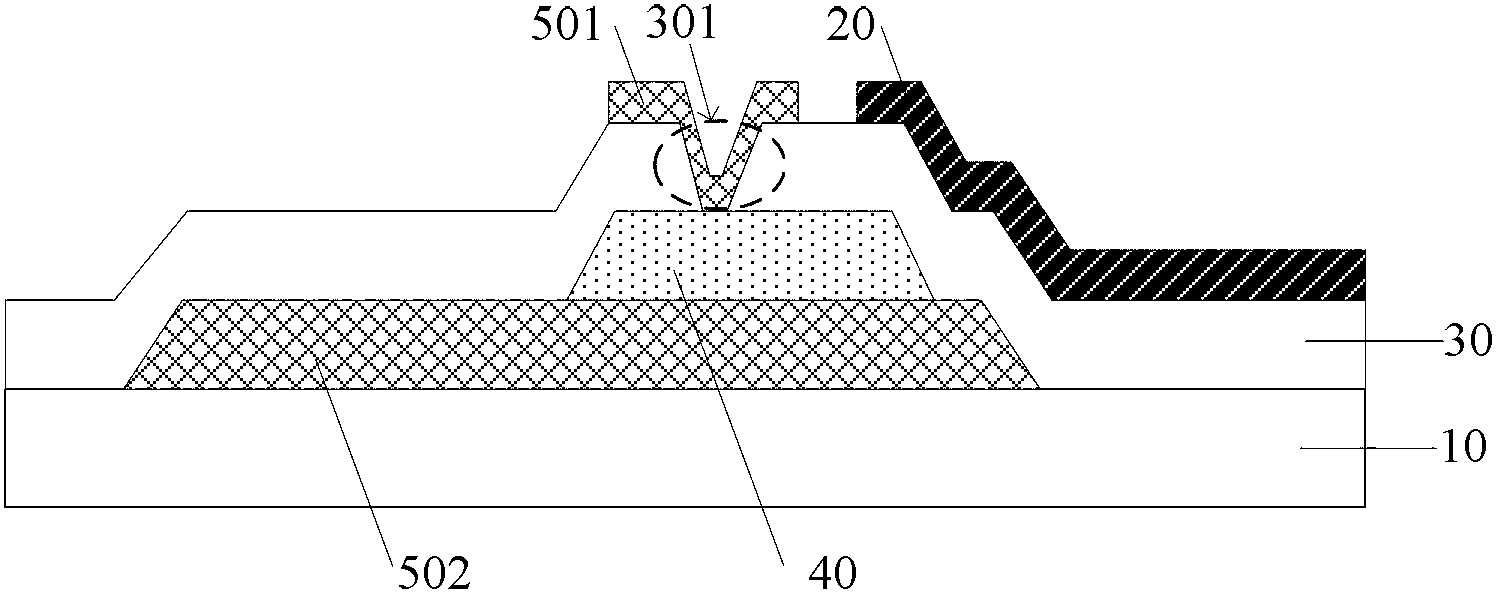

[0060] Embodiment 2 provides a thin film transistor, such as Figure 5 As shown, the thin film transistor includes: a drain 502 disposed on the base substrate 10, an active layer 40 disposed above the drain, a source 501 disposed above the active layer, and a drain 502 disposed above the drain. There is a gate insulating layer 30 between the active layer and the source, and a gate 20 disposed above the gate insulating layer.

[0061] Wherein, the active layer 40 includes an amorphous silicon semiconductor layer 401 in the middle, a first ohmic contact layer 402 above the amorphous silicon semiconductor layer, and a second ohmic contact layer below the amorphous silicon semiconductor layer. Layer 403.

[0062] The drain 502 is in contact with the second ohmic contact layer 403 of the active layer 40, the source 501 is in the same layer as the gate 20 but not connected, and the source 501 is arranged on the gate The first via hole 301 on the insulating layer 30 is in contact w...

Embodiment 3

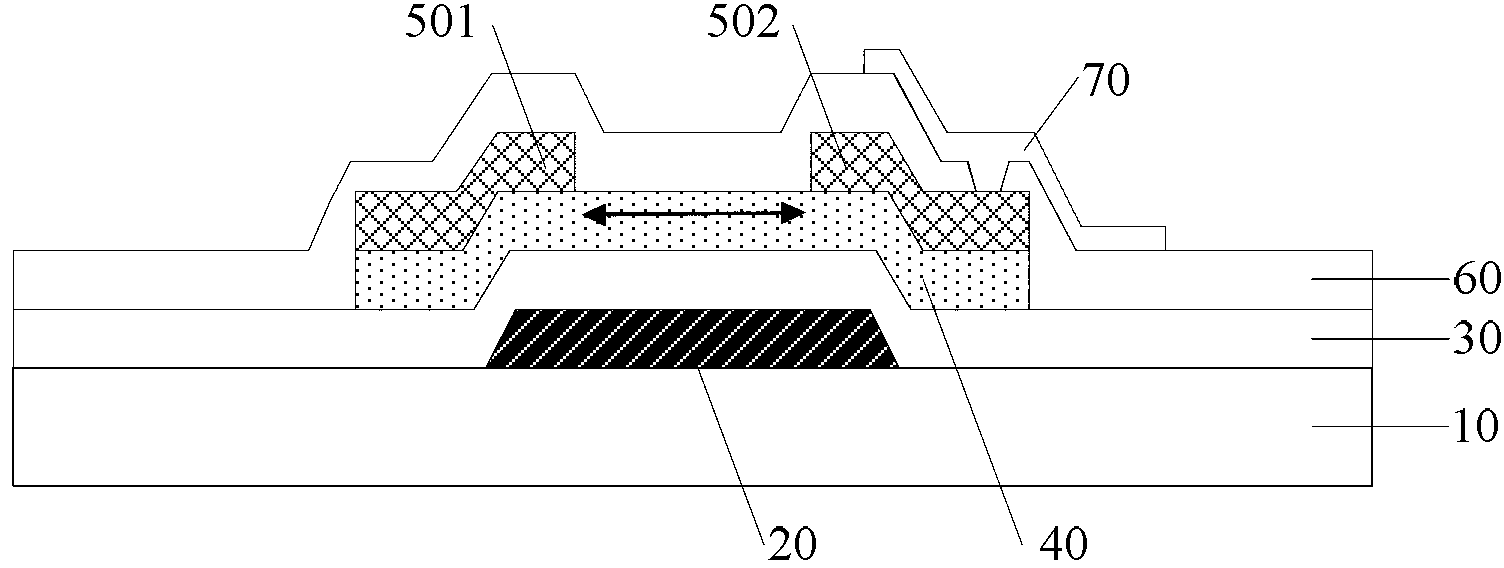

[0071] Embodiment 3 provides an array substrate, referring to Image 6 As shown, the array substrate includes from bottom to top: a base substrate 10, a source 501 disposed on the base substrate and a data line (not marked in the figure) connected to the source, and a source 501 disposed on the source The upper active layer 40, the gate insulating layer 30 arranged above the active layer 40, and the drain 502 and the gate 20 arranged on the same layer but not connected above the gate insulating layer 30, and the gate 20 A connected gate line (not marked in the figure), wherein the gate insulating layer 30 is provided with a first via hole 301, and the drain electrode 502 is in contact with the active layer 40 through the first via hole 301. In addition, it also includes: The protection layer 60 , and the pixel electrode 70 disposed on the protection layer, and the pixel electrode 70 is connected to the drain electrode 502 through the second via hole 601 disposed on the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com