Pressure gauge

A pressure gauge and watch case technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems that are not conducive to improving the social competitiveness of enterprises, increase the production cost of pressure gauges, and the high price of copper metal, so as to alleviate the problem of copper resources. Shortage, reduce the consumption of copper, save the effect of copper materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

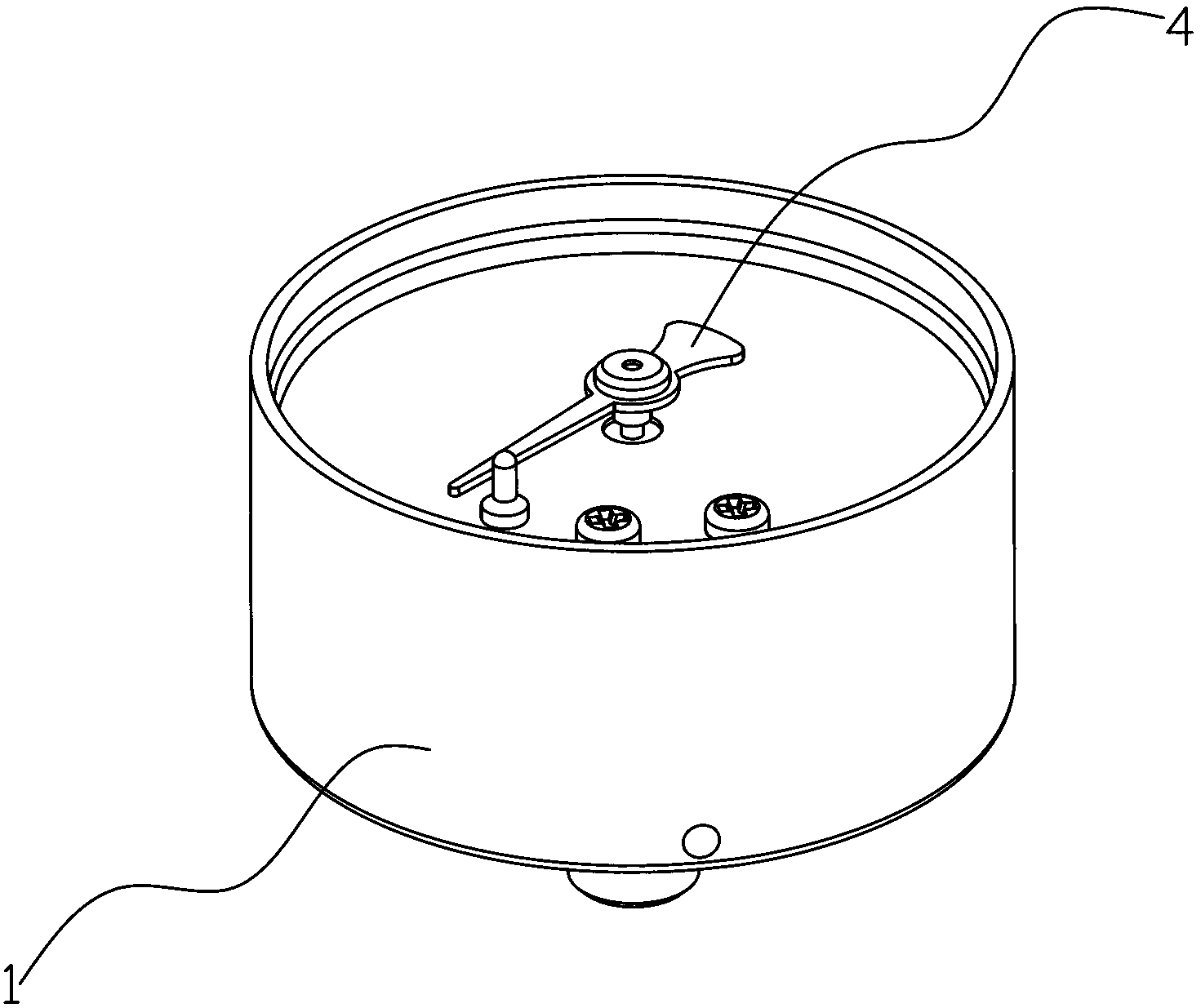

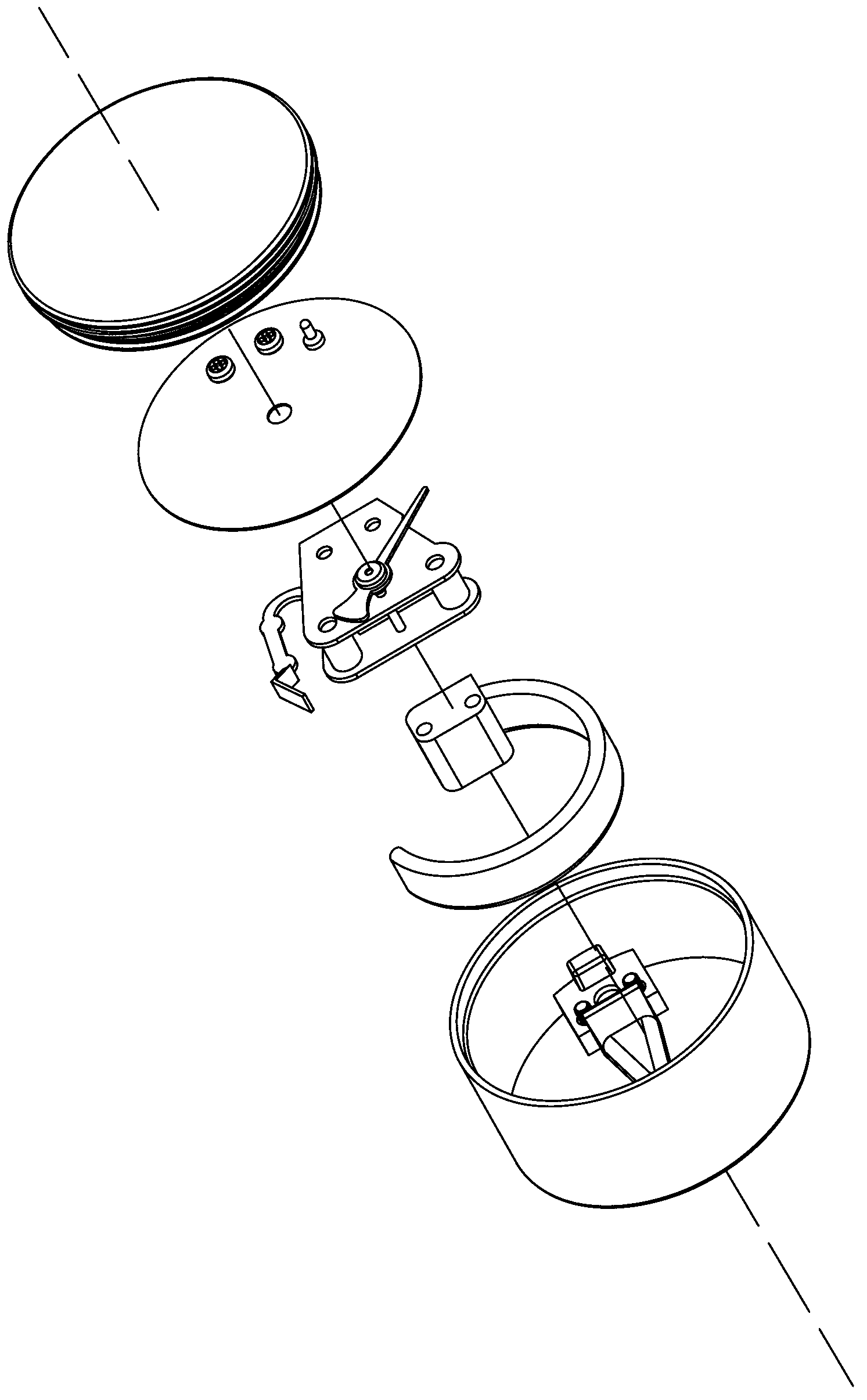

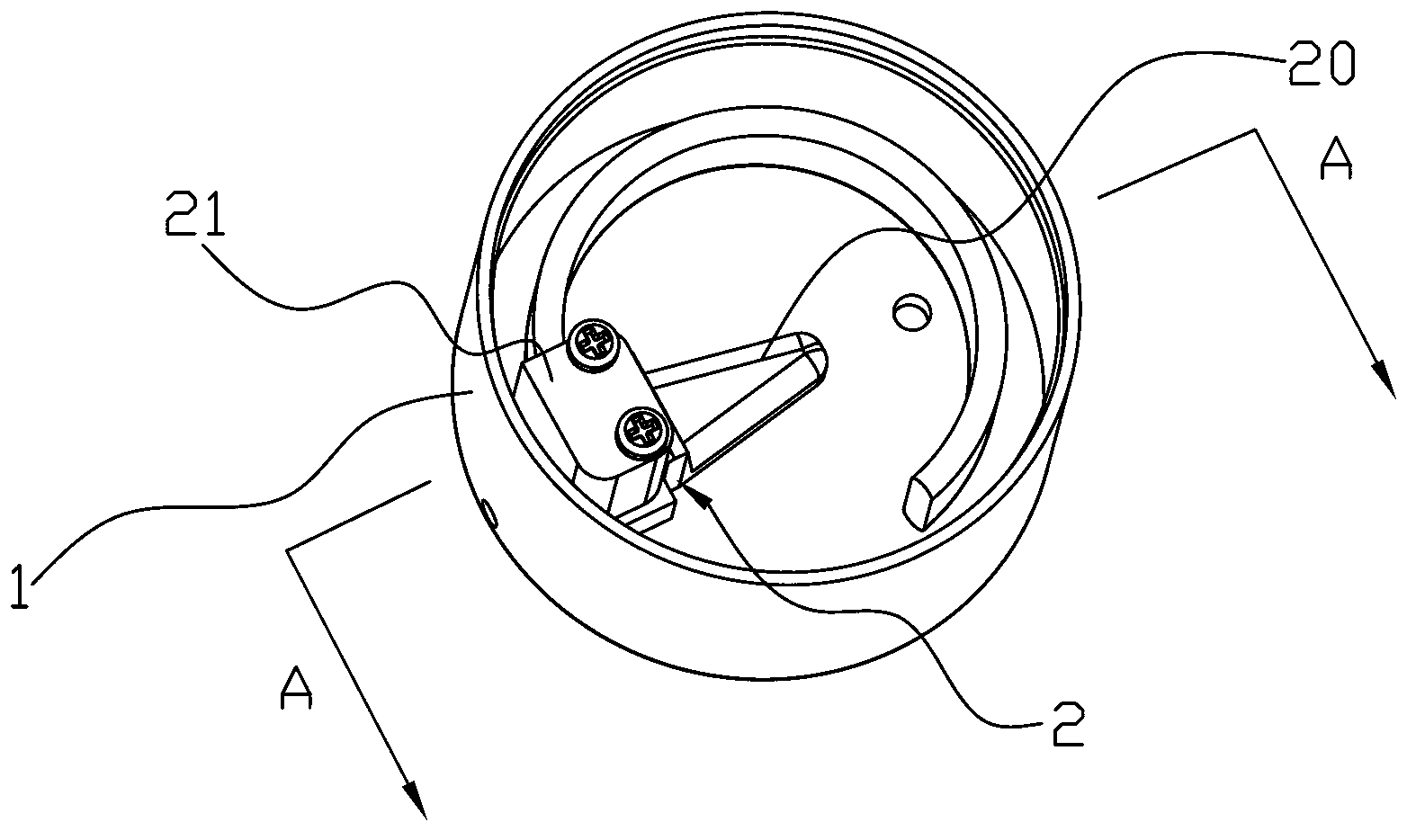

[0016] refer to figure 1 As shown in Fig. 5, the pressure gauge is mainly composed of a watch case 1, a fluid input part 2, a Barton tube 3, a pointer 4, a movement 5, an indicating panel 6 and a transparent mask 7, and the fluid input part 2 is arranged on the watch case 1 The mounting seat 20 on the bottom surface of the inner surface and the connector 21 that can be fixedly installed on the mounting seat 20 are spliced together. The above-mentioned mounting seat 20 and the base 1 are preferably manufactured through injection molding, and the connecting head 21 is preferably made of copper material. Of course, it can also be made of plastic or other materials. The interior of the mounting base 20 and the connector 21 is provided with a fluid delivery pipeline 22 capable of delivering fluid to the inside of the Barton tube 3, and one end of the Barton tube 3 is fixedly installed On the connector 21, a sealing ring 202 is provided at the junction of the above-mentioned mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com