Preparation method of high temperature hot water for industrial use

A high-temperature hot water, industrial technology, applied in lighting and heating equipment, fluid heaters, etc., can solve the problems of high humidity, steam boiler pollution, high cost, etc., to avoid system damage, improve production quality, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

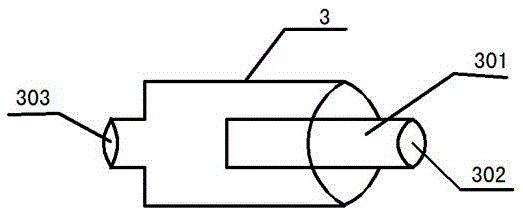

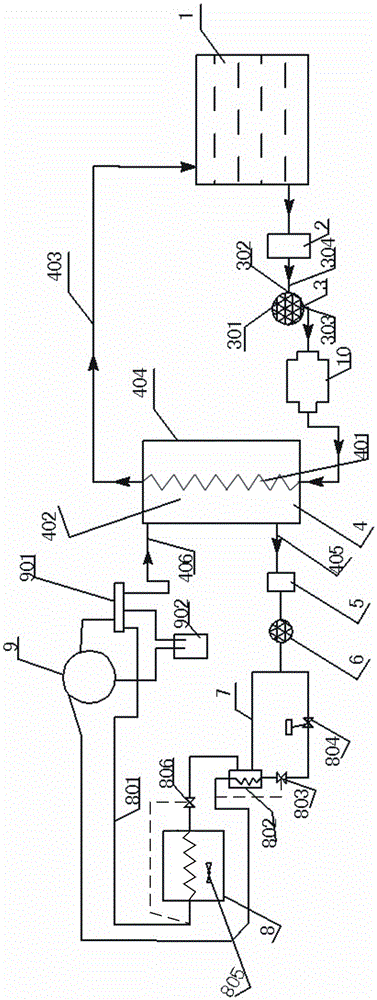

[0036] A method for preparing high-temperature hot water for industrial use, a hot water exchange circulation system, an air exchange heating circulation system and a hot water pool 1 for cleaning workpieces constitute the circulation heating of high-temperature hot water, the hot water exchange circulation system, It includes a hot water pool 1 , a pipeline filter 3 , a hot water exchanger 4 , a high temperature water exchange pipe 403 and a water pump 10 .

[0037] The air exchange heating circulation system includes a hot water exchanger 4 , a liquid storage tank 5 , a gas filter 6 , an air exchanger 8 and a compressor 9 .

[0038] In the working state, along with the reduction of the water temperature of the hot water pool, while the working path of the heat exchanger 802 and the air exchanger 8 is opened, the speed of the hot air blower 805 is increased to form the heat exchanger 802, the air exchanger 8 and the compressor 9 respectively. The linked double exchange heatin...

Embodiment 1

[0053] The present invention is a preparation method of industrial high-temperature hot water, which adopts a hot water pool 1, a low-temperature water filter pool 2, a pipeline filter 3, a heat exchanger 4, a liquid storage tank 5, a gas filter 6, and a heat exchange pipeline 7 , air exchanger 8, heat exchanger 802, compressor 9 and water pump 10 constitute the air energy heating system.

[0054] Wherein the hot water pool 1 is connected with the low temperature water filter pool 2, the low temperature water filter pool 2 is connected with the pipeline filter 3, the pipeline filter 3 is connected with the water pump 10, the water pump 10 is connected with the water inlet of the hot water exchanger 4, and the heat The water outlet of the water exchanger 4 is connected to the hot water pool 1 through a high temperature water exchange pipe 403 to form a hot water circulation exchange system.

[0055] Such as figure 2 As shown, the hot water exchanger 4 adopts a coil type excha...

Embodiment 2

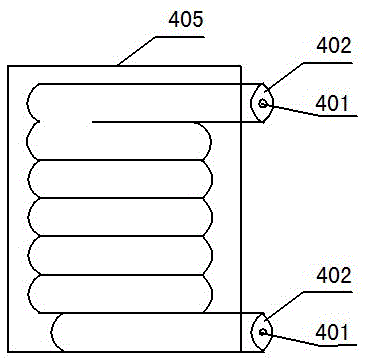

[0062] Such as Figure 4 As shown, the heat exchanger 4 adopts a straight pipe exchanger, and the straight pipe exchanger is composed of a hot water heater 401, a hot air exchanger 402 and a shell, and the hot water heater 401 is arranged on the hot air exchanger 402 Inside, the outlet of the hot air exchanger 402 is connected to the liquid storage tank 5 through the low-temperature gas exchange tube 405 , the liquid storage tank 5 is connected to the gas filter 6 , and the gas filter 6 is connected to the heat exchanger 802 through the heat exchange pipeline 7 .

[0063] There are two outlets on the heat exchanger 802, one of the outlets of the heat exchanger 802 is directly connected to the compressor 9, and the gas exchanged from the heat exchanger 802 enters through the four-way valve under the action of the compressor 9 Hot water exchanger 4.

[0064] The other outlet of the plate heat exchanger 802 is connected to the air exchanger 8 through the thermal expansion valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com