Anti-dumping valve

A technology of anti-dumping and dumping valves, which is applied in the direction of adding non-fuel substances, engine components, liquid fuel feeders, etc. to the fuel to achieve the effects of high safety, improved dimensional accuracy, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

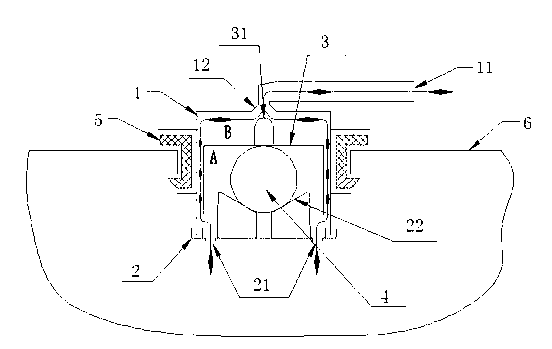

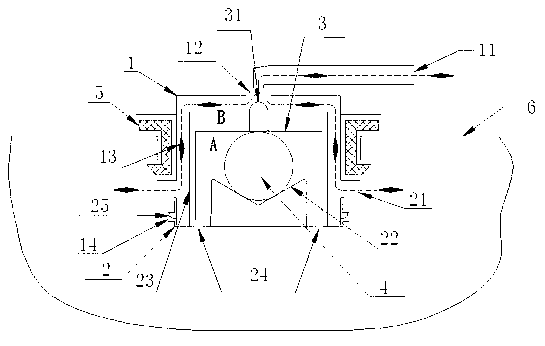

[0038] combine figure 2 As shown, in an anti-dumping valve of the present invention, the valve body 1 and the valve seat 2 are buckled to form a valve chamber B, and the top of the valve body 1 is integrally provided with a first vent 11, and the first vent 11 and the valve chamber B pass through the valve The port 12 is connected, and the center of the bottom of the valve seat 2 is integrally provided with a conical pit 22, and a cross groove can be provided in the longitudinal direction of the conical pit 22;

[0039] A cover-shaped float 3 is arranged above the valve seat 2, and a valve core 31 that cooperates with the valve port 12 and can close the first vent port is provided on the top outside of the float 3. The valve core 31 and the valve port 12 can be in contact with a spherical surface. It can also be contacted with a rounded surface, and the line contact can ensure the tightness of the valve closing. The conical structure can ensure that it can be effectively rese...

Embodiment 2

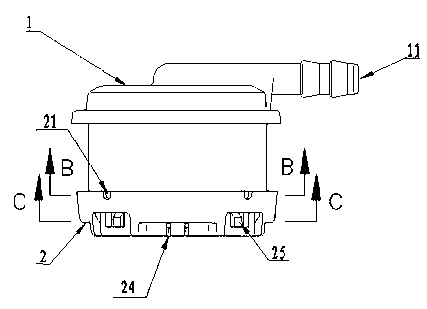

[0046] combine Figure 2 to Figure 11 As shown, an anti-dumping valve, on the basis of the structure of Embodiment 1, the number of the second air vent 21, the liquid discharge port 24, the number of fastening holes 14, and the number of fastening bosses 25 are all set to four, as a kind of implementation.

Embodiment 3

[0048] combine Figure 12 As shown, another implementation of the anti-dumping valve is based on Example 1, and on the basis of retaining the structural design of setting the isolation cylinder 23 in the valve and setting the second vent 21 on the side, the valve The body 1 and the valve seat 2 are connected in the form of welding instead of the connection method of the elastic snap-fit structure. It can also achieve the effect of keeping the fuel tank pressure in a safe range all the time during work, and has the effect of preventing accidental leakage of fuel through the anti-dump valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com