Electroplating method for PCB plate and apparatus

A PCB board and electroplating device technology, applied in the field of PCB board electroplating methods and devices, can solve problems such as inability to guarantee the exchange effect of PCB electroplating solution, insufficient thickness of the electroplating layer in holes, and low flow of electroplating solution, etc., so as to improve deep plating ability , Uniform thickness and full flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

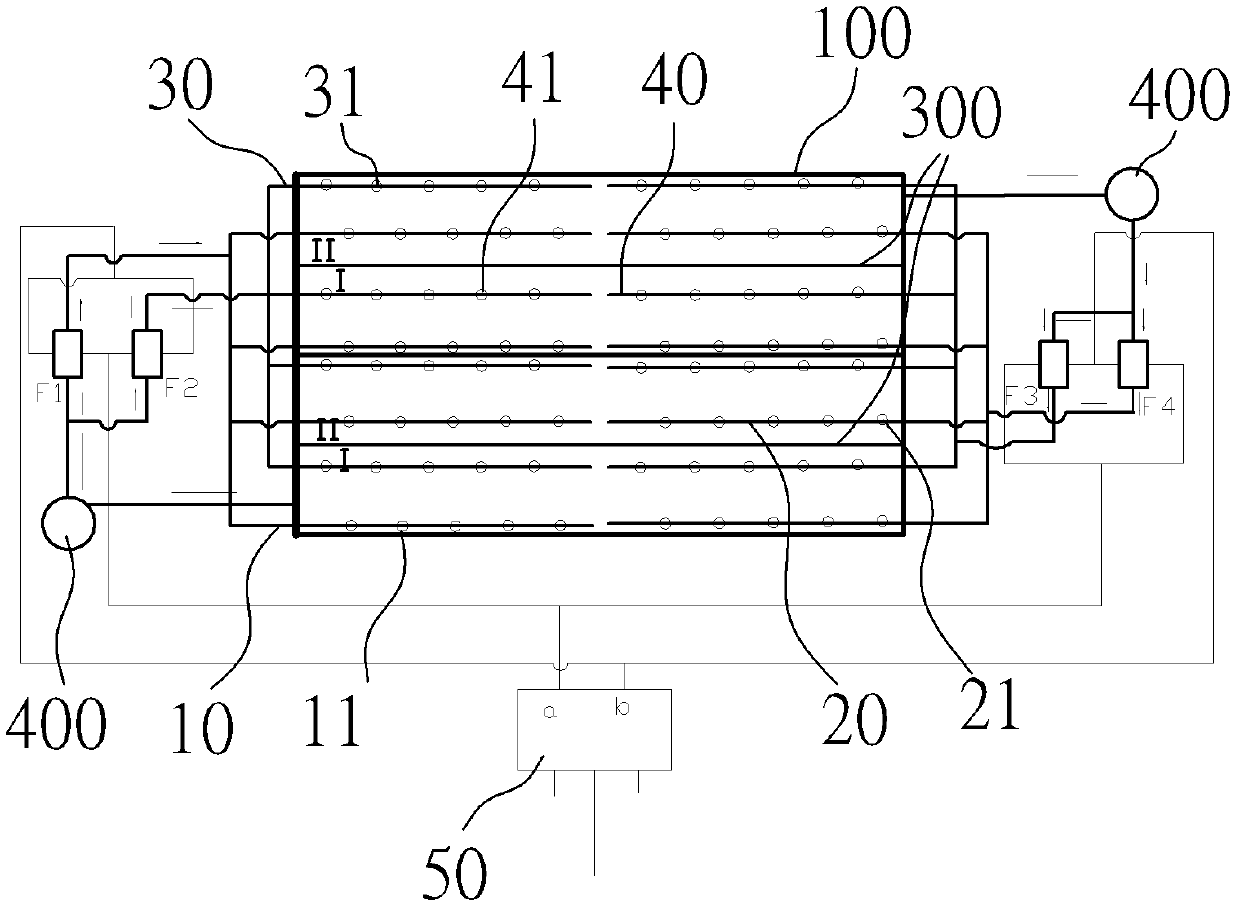

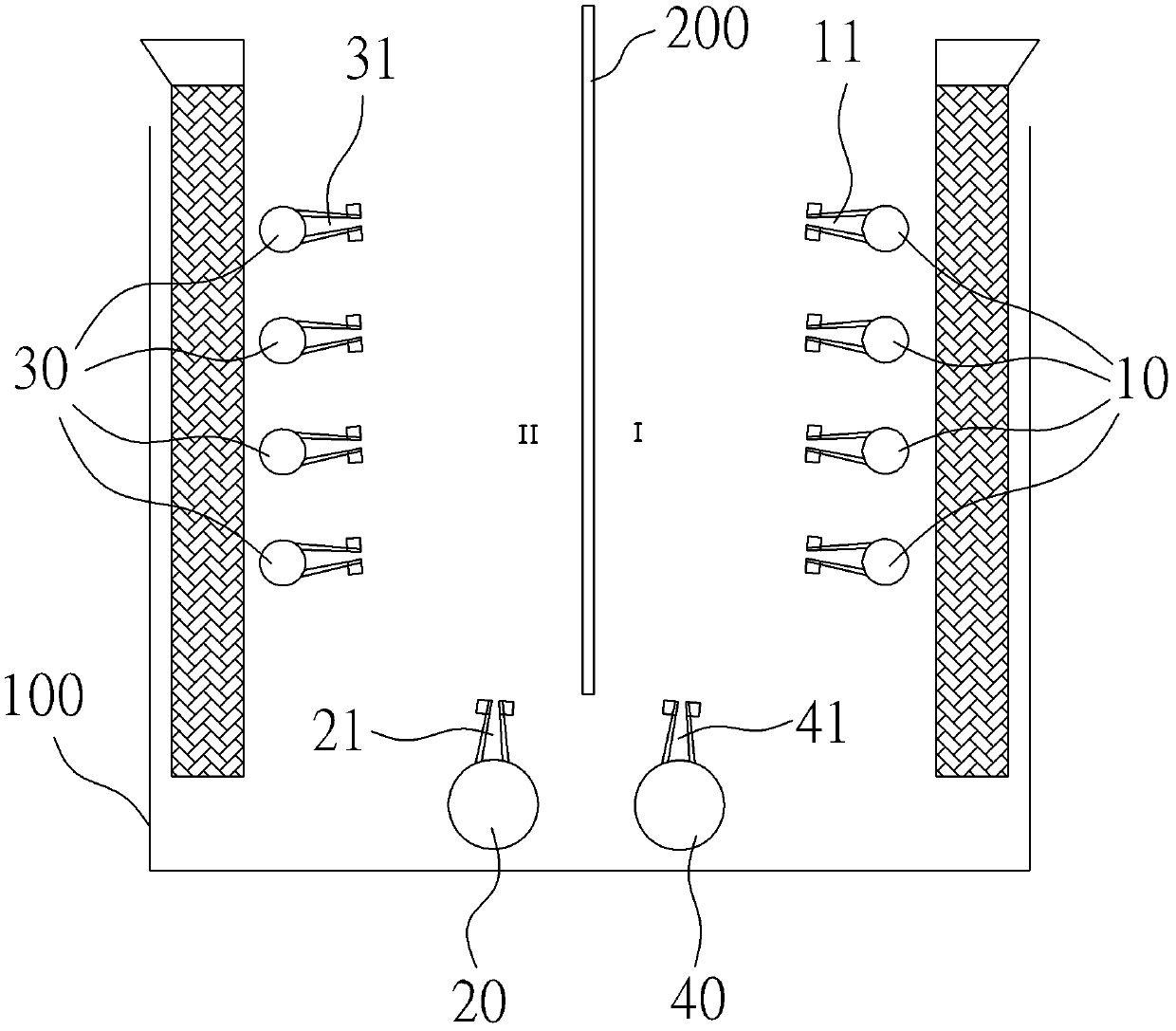

[0012] Please refer to Figure 1~Figure 2 , the PCB board electroplating device of the embodiment of the present invention, it can alternately carry out side spray on both sides of PCB board 200, and carry out bottom spray to another board surface while carrying out side spray to one board surface, electroplating solution forms turbulent flow, The two sides of the hole of the PCB board have a large negative pressure due to the different flow rates of the electroplating solution. The flow effect of the electroplating solution in the hole is sufficient, the exchange capacity is strong, the deposition speed of copper ions is fast, and the deep plating ability is improved. The thickness of electroplated copper in the hole is sufficient and uniform.

[0013] The PCB board electroplating device includes an electroplating tank 100 and a holding assembly 300 for holding the PCB board 200 immersed in the electroplating solution of the electroplating tank 100. The electroplating solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com