Technology for reducing residual stress of complex aviation die forging through adopting local die pressing method

A residual stress and die forging technology, which is applied in the field of partial die pressing method of complex aviation die forgings to reduce residual stress, can solve the problems of high requirements for component use, processing deformation, complex shape and structure, and achieves low equipment load capacity requirements and quenching residual stress. Reduce, reduce the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

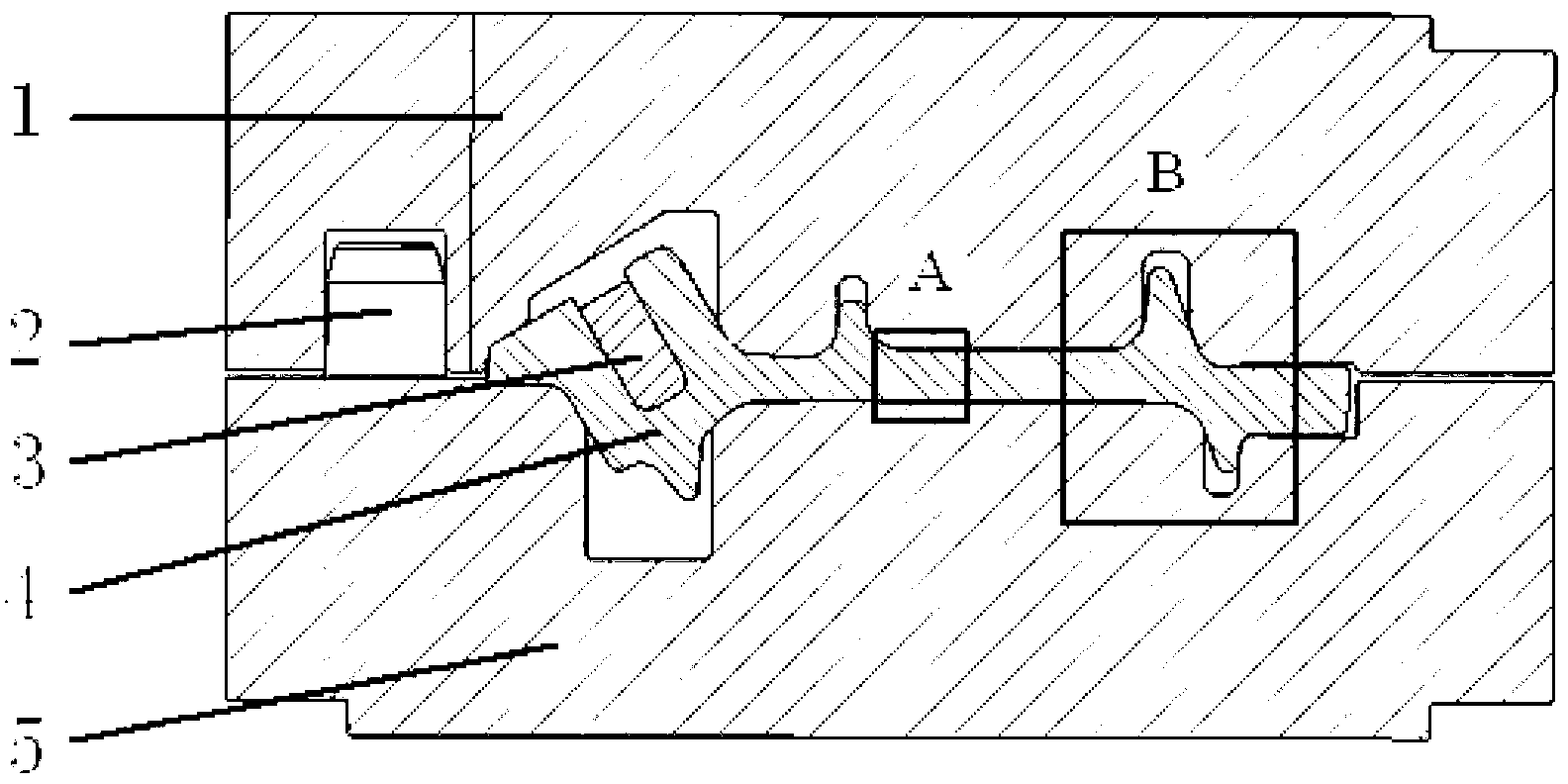

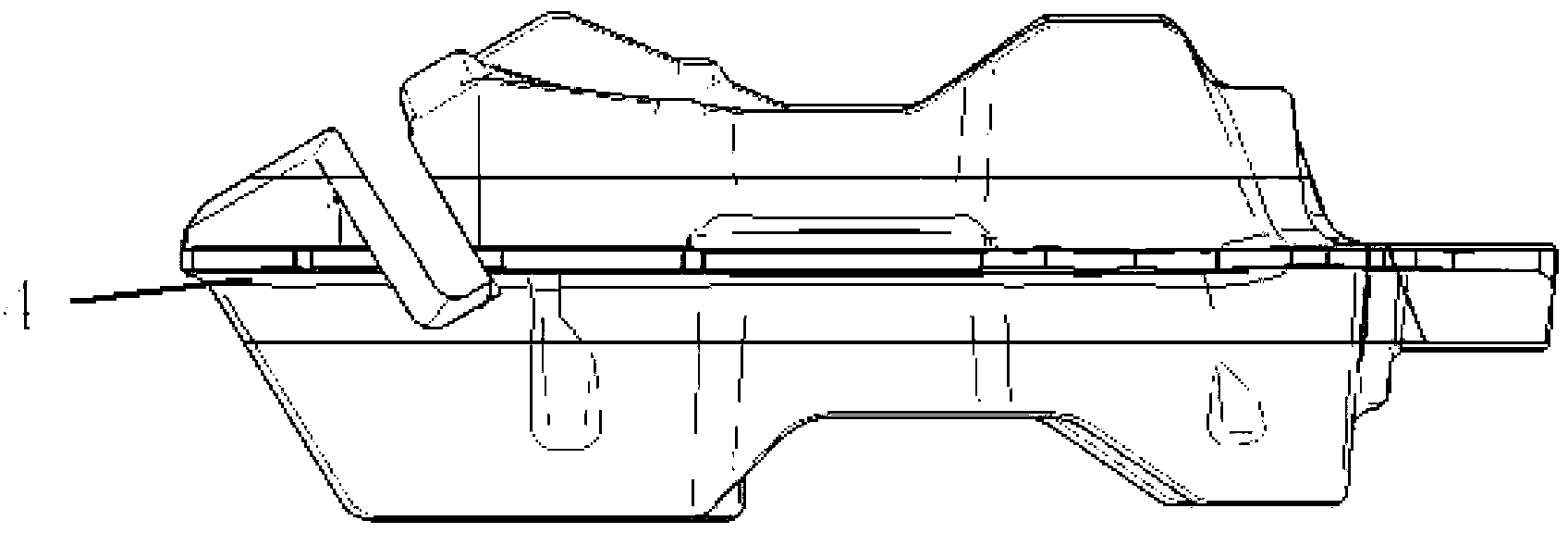

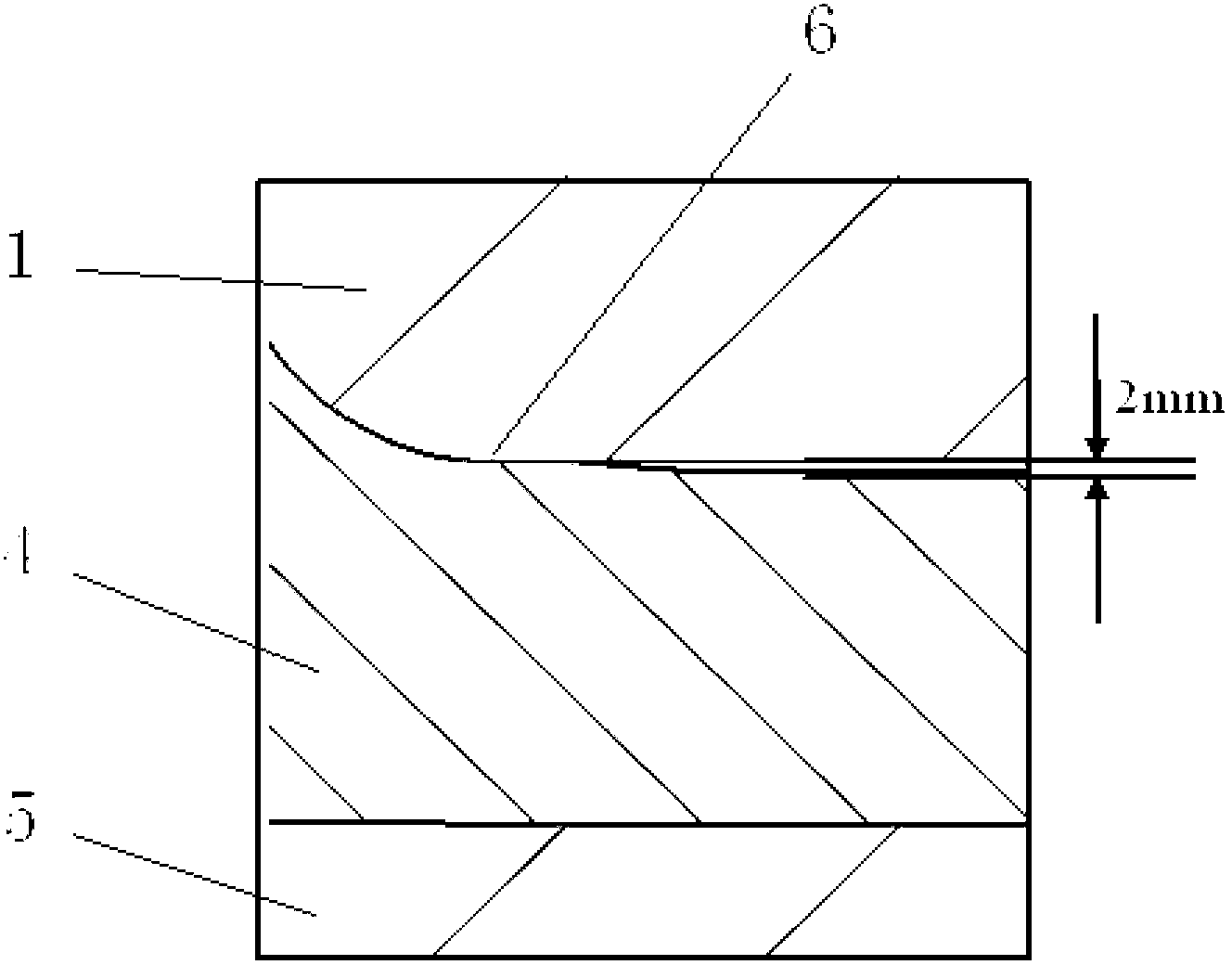

[0022] see figure 1 and figure 2 , the process of reducing residual stress by local molding method for complex aviation die forgings. The quenching residual stress concentration area where the rib plate and the web intersect of the forging 4 is molded, and the half part of the rib plate of the forging 4 is not molded, so that the forging 4 can be demoulded smoothly after the molding cold deformation process.

[0023] see figure 1 , the head groove of forging 4 is relatively weak after machining. In order to avoid the excessive extrusion of upper die 1 and lower die 5 on the head of forging 4, resulting in deformation and cracking inside the head groove, the groove of the head of forging 4 An insert 3 is placed in the groove so that the forging 4 is supported during the molding process.

[0024] see figure 1 , the forging 4 has only a smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com