High-yield reactor for protein production, and production method and application thereof

A bioreactor and reactor technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment and methods, etc., can solve the high time and capital cost, can not be retained Target protein, low single-batch protein yield, etc., to reduce abnormal structural changes, increase operational flexibility, and improve product yield and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

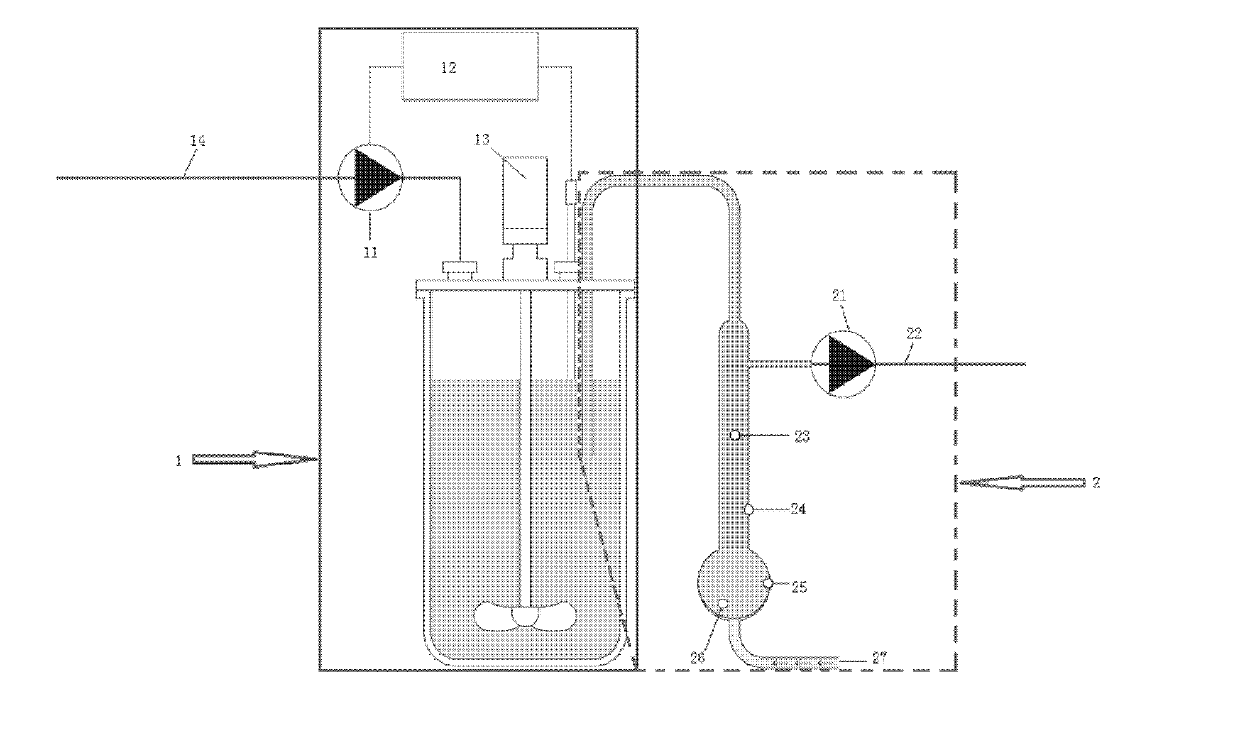

[0056] Using the above-mentioned high-yield reactor to carry out the production method of monoclonal antibody, including steps:

[0057] (1) Connect the bioreactor 1 with the ATF perfusion device 2 of the corresponding model to complete the off-line sterilization or in-situ sterilization procedure;

[0058] (2) Using the growth medium, seed the cells at 0.3×10 6 ~1×10 6 Inoculate bioreactor 1 to the working volume at the density of cells / mL, control temperature (36-37°C), pH (6.8-7.2), dissolved oxygen concentration (40%-60%), and tank pressure (2-8psi), every 24-hour sampling to detect cell number and biochemical indicators;

[0059] Among them, the biochemical indicators include: pH, O 2 Dissolved partial pressure, CO 2 Partial pressure of dissolution, glutamine content, glutamic acid content, glucose content, lactic acid content, NH 4 + Level, Na + Level, K + Level, Ca + level, osmotic pressure, etc.;

[0060] (3) When the living cell density increased to 3×10 6...

Embodiment 2

[0069] According to the general fed-batch process, although CHO cells for the production of anti-CD20 antibodies can grow to 7×10 6 The living cell density of cells / mL, but the expression level of the target protein anti-CD20 antibody is only 0.25 g / L.

[0070] However, according to the production method of Example 1, the CHO cells for the production of anti-CD20 antibodies have reached the highest cell growth density nearly 10 times that of the general fed-batch process and 8 times the target protein yield (as shown in Figure 5).

Embodiment 3

[0072] According to the production method of Example 1, the CHO cells for the production of Humira monoclonal antibody reached a maximum cell growth density of 140 × 10 in just 11 days. 6 The growth of cells / mL and the yield of target protein (Humira monoclonal antibody) of nearly 9 g / L (as shown in Figure 6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com