Supported non-metallocene catalyst, its preparation method and application

A non-metallocene and catalyst technology, applied in the field of non-metallocene catalysts, can solve the problems of low catalytic activity, difficult to control the carrier molding process and particle shape, difficult to control the polymer shape, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

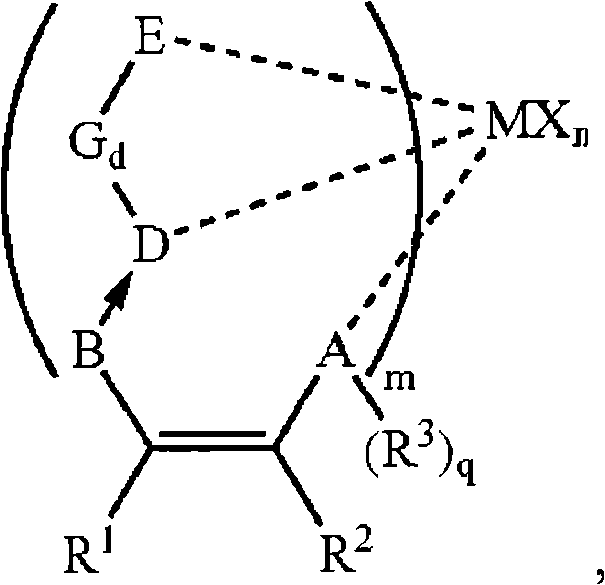

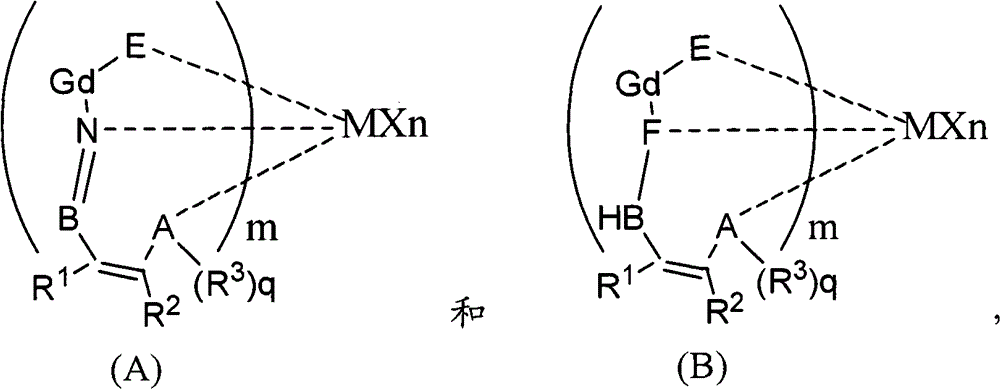

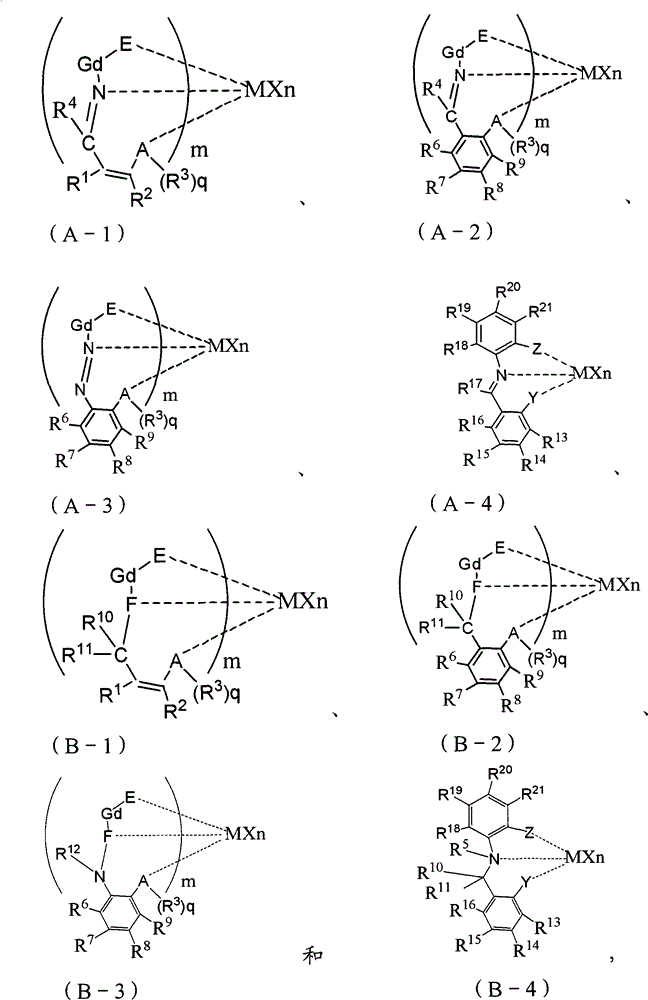

Image

Examples

no. 1 approach

[0165] In the context of the present invention, unless clearly defined otherwise, or the meaning is beyond the understanding of those skilled in the art, hydrocarbon or hydrocarbon derivative groups with more than 3 carbon atoms (such as propyl, propoxy, butyl , Butane, butene, butenyl, hexane, etc.) have the same meaning when the prefix "positive" is not prefixed. For example, propyl is generally understood as n-propyl, and butyl is generally understood as n-butyl.

[0166] The present invention relates to a method for preparing a supported non-metallocene catalyst, which includes the following steps: contacting a porous support optionally undergoing thermal activation treatment, a Grignard reagent, a halogenated reagent and a non-metallocene complex in the presence of a solvent, The step of obtaining the supported non-metallocene catalyst.

[0167] According to the present invention, the porous support, Grignard reagent, halogenated reagent and non-metallocene complex optionally...

Embodiment 1

[0301] The Grignard reagent is methylmagnesium chloride (MeMgCl), the solvent for dissolving the Grignard reagent is tetrahydrofuran, the halogenated reagent is chloro-n-butane, the porous carrier is silica, that is, silica gel, the model is ES757 of Ineos, non-metallocene The structure of the complex is compound of.

[0302] First, the silica gel is continuously calcined at 600°C under a nitrogen atmosphere for 4 hours to be thermally activated.

[0303] Weigh 3g of the non-metallocene complex and dissolve it in the halogenated reagent at room temperature to make a homogeneous solution for later use. The thermally activated silica gel is added to the Grignard reagent solution at room temperature, and stirred at room temperature to form a uniform slurry. The mixed solution of the non-metallocene complex and the halogenated reagent is added dropwise to the uniform slurry at room temperature, and the dropping time is 30 minutes. After the dropwise addition was completed, it was st...

Embodiment 2

[0307] The Grignard reagent uses ethyl magnesium chloride (EtMgCl), the solvent for dissolving the Grignard reagent uses ether, the halogenated reagent uses chloroethane, and the non-metallocene complex uses The porous carrier was changed to 955 type silica gel from Grace Company, and it was calcined continuously for 8 hours under a nitrogen atmosphere at 400°C for thermal activation.

[0308] Weigh 6.4 g of the non-metallocene complex, add it to the Grignard reagent solution at room temperature, and then add the thermally activated porous carrier at room temperature to make a slurry. Weigh the halogenated reagent and dissolve it in the solvent for dissolving Grignard reagent (accounting for half of the total) at room temperature to make a solution. The halogenated reagent solution is added dropwise to the aforementioned slurry at room temperature, and the dropping time is 30 minutes. After the dropwise addition was completed, it was stirred at room temperature for 2 hours. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com