Method for recycling waste silicon slag discharged in production of zirconyl chloride

A zirconium oxychloride and silicon slag technology, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of increasing production equipment, waste of resources, environment, pollution, etc., to save chemical raw materials and achieve environmental benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] The method for recycling the waste silicon slag discharged in the production of zirconium oxychloride of the present invention comprises the following steps:

[0111] ①. Pretreatment of waste silicon slag

[0112] a. Neutralization

[0113]Put the waste silicon slag to be treated into the reaction kettle, add an appropriate amount of water, stir and mix evenly, adjust the pH value to 6.5-7.0 with sodium hydroxide solution, and prepare for filtration and washing;

[0114] b. Filtration and washing

[0115] After centrifuging and washing the material reconciled in step a, the filter cake is used for the subsequent preparation of sodium silicate solution;

[0116] c. Sampling test

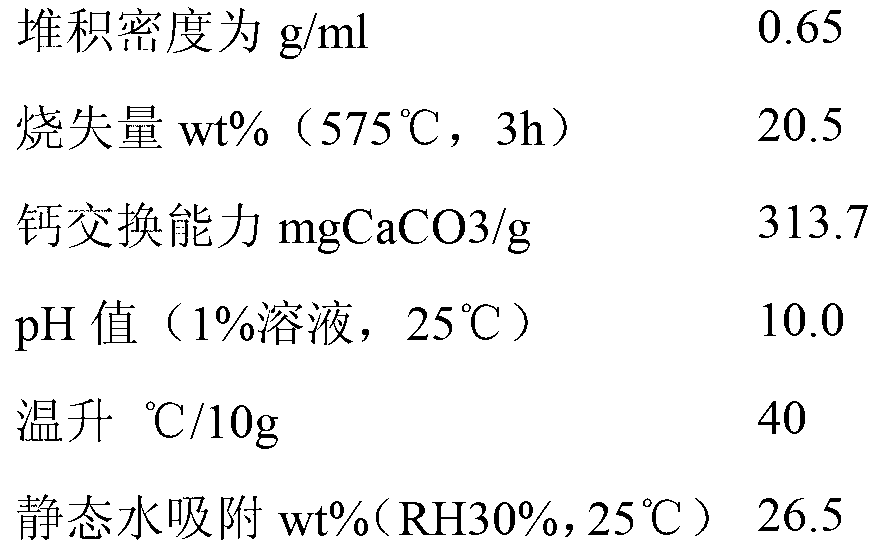

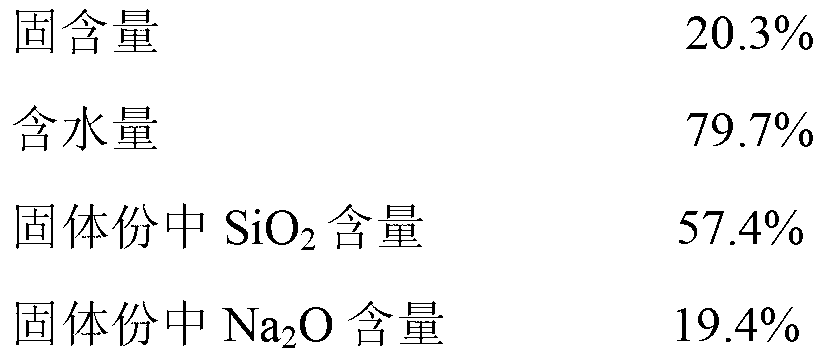

[0117] Take out the sample from the filter cake of step b, measure the solid content in the filter cake, calculate the moisture content; then measure the SiO in the solid waste silicon slag 2 and Na 2 The content of O is used for calculation and measurement of subsequent ingredients;

[0...

Embodiment 2

[0155] The method for recycling the waste silicon slag discharged in the production of zirconium oxychloride of the present invention comprises the following steps:

[0156] ①. Pretreatment of waste silicon slag

[0157] a. Neutralization

[0158] Put the waste silicon slag to be treated into the reaction kettle, add an appropriate amount of water, stir and mix evenly, adjust the pH value to 7.0 with sodium hydroxide solution, and prepare for filtration and washing;

[0159] b. Filtration and washing

[0160] After centrifuging and washing the material reconciled in step a, the filter cake is used for the subsequent preparation of sodium silicate solution;

[0161] c. Sampling test

[0162] Take out the sample from the filter cake of step b, measure the solid content in the filter cake, calculate the moisture content; then measure the SiO in the solid waste silicon slag 2 and Na 2 The content of O is used for calculation and measurement of subsequent ingredients;

[0163...

Embodiment 3

[0201] The method for recycling the waste silicon slag discharged in the production of zirconium oxychloride of the present invention comprises the following steps:

[0202] ①. Pretreatment of waste silicon slag

[0203] a. Neutralization

[0204] Put the waste silicon slag to be treated into the reaction kettle, add an appropriate amount of water, stir and mix evenly, adjust the pH value to 7.0 with sodium hydroxide solution, and prepare for filtration and washing;

[0205] b. Filtration and washing

[0206] After centrifuging and washing the material reconciled in step a, the filter cake is used for the subsequent preparation of sodium silicate solution;

[0207] c. Sampling test

[0208] Take out the sample from the filter cake of step b, measure the solid content in the filter cake, calculate the moisture content; then measure the SiO in the solid waste silicon slag 2 and Na 2 The content of O is used for calculation and measurement of subsequent ingredients;

[0209...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com