Multifunctional and full-automatic steel pipe transfer operation machine

A fully automatic and multi-functional technology, applied in metal processing and other fields, can solve the problems of high equipment cost, poor work efficiency, few dense continuous station layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

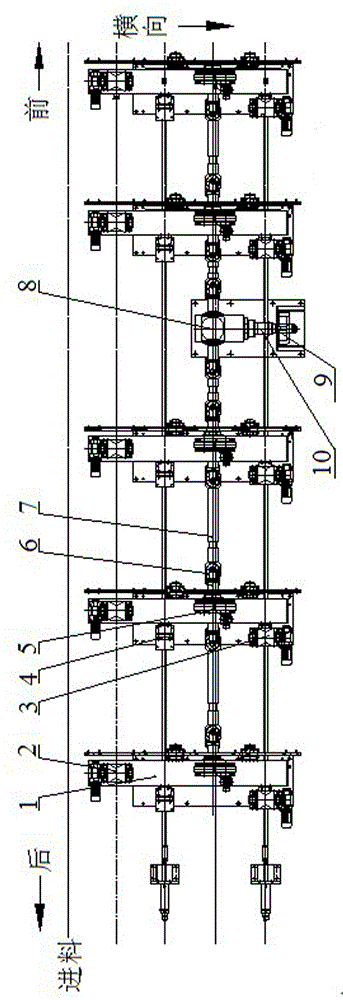

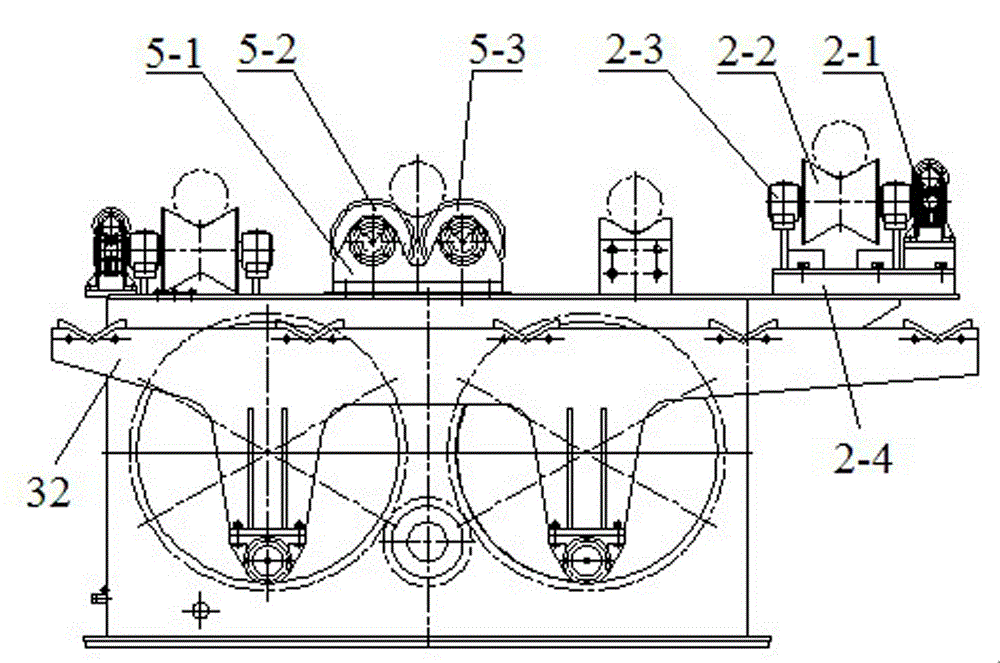

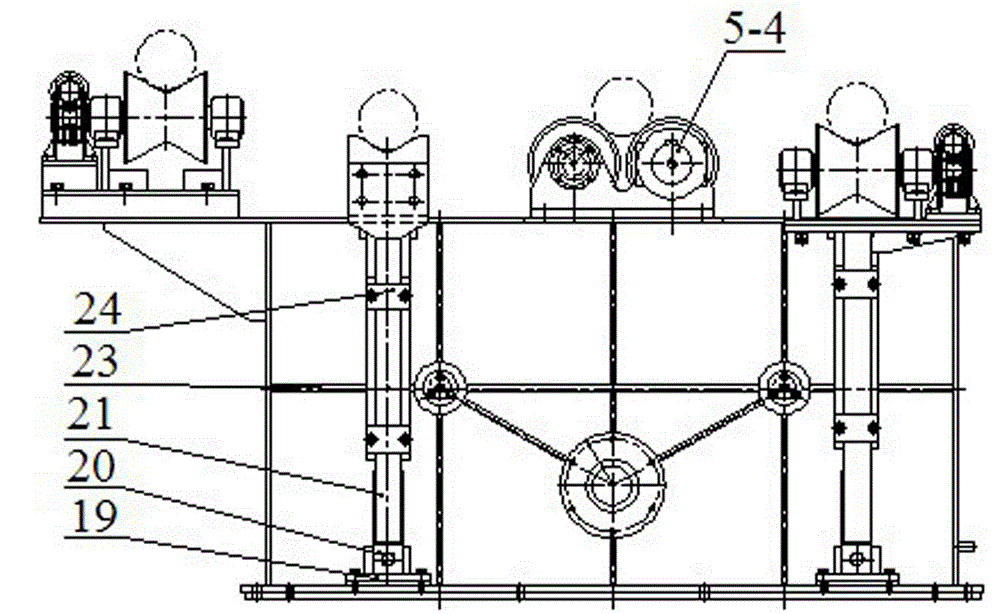

[0017] Such as figure 1 As shown, the multi-functional automatic steel pipe material shifting operation machine of the present invention includes a reducer 8 with bilateral output power, and the reducer 8 is connected to the hydraulic motor 9 through a gear coupling 10; the two sides of the reducer 8 are respectively arranged side by side There are multiple gear-type stepping and traversing mechanisms 1 . The structure of the gear type stepping and traversing mechanism 1 is as follows: Figure 2-5 Shown, comprise hollow box body 37, be provided with front support assembly 27 on the box body front vertical plate 17 of box body 37, be provided with drive shaft 28 in the front support assembly 27, one end of drive shaft 28 passes box body Front vertical plate 17 stretches out outside casing 37, is provided with rear support assembly 25 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com