An automatic boxing device

A technology of boxing and equipment, applied in the field of automatic boxing equipment, can solve the problems of unsuitable ground space, complex equipment structure, low boxing speed, etc., meet the needs of boxing actions, have a wide range of applications, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

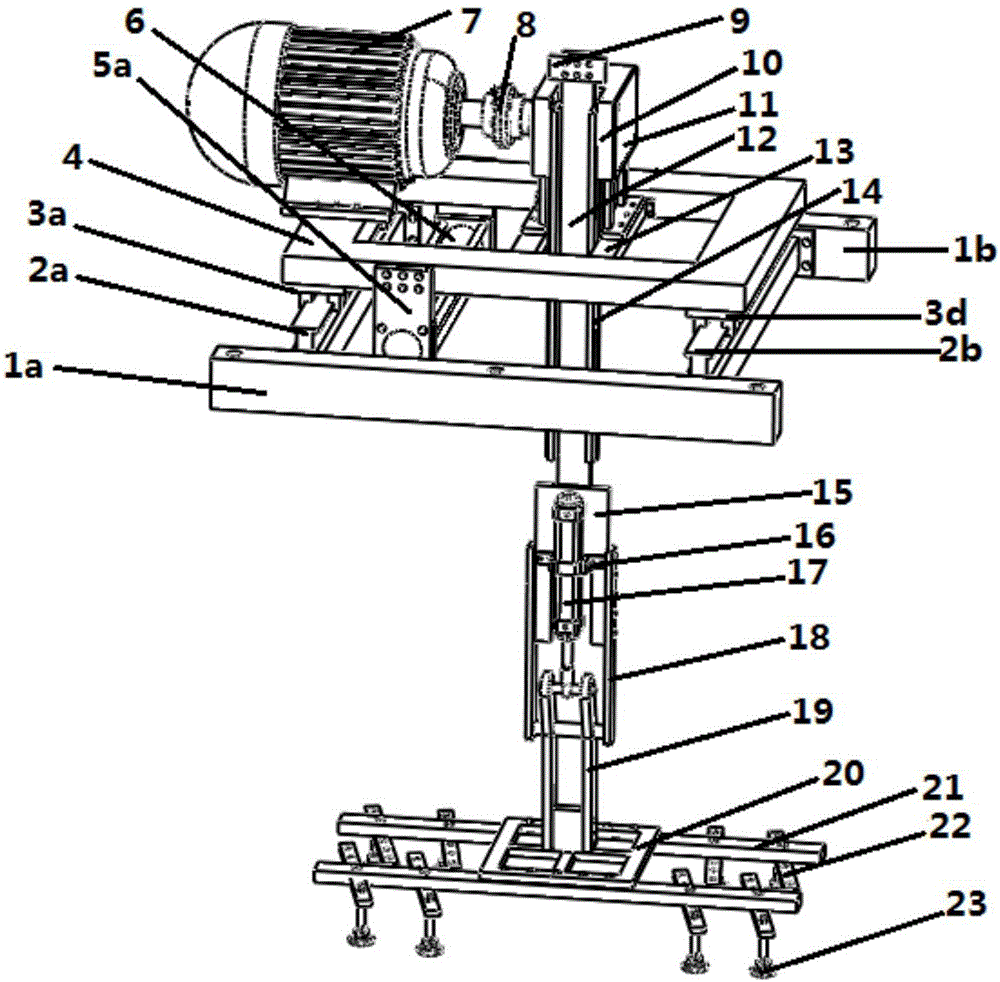

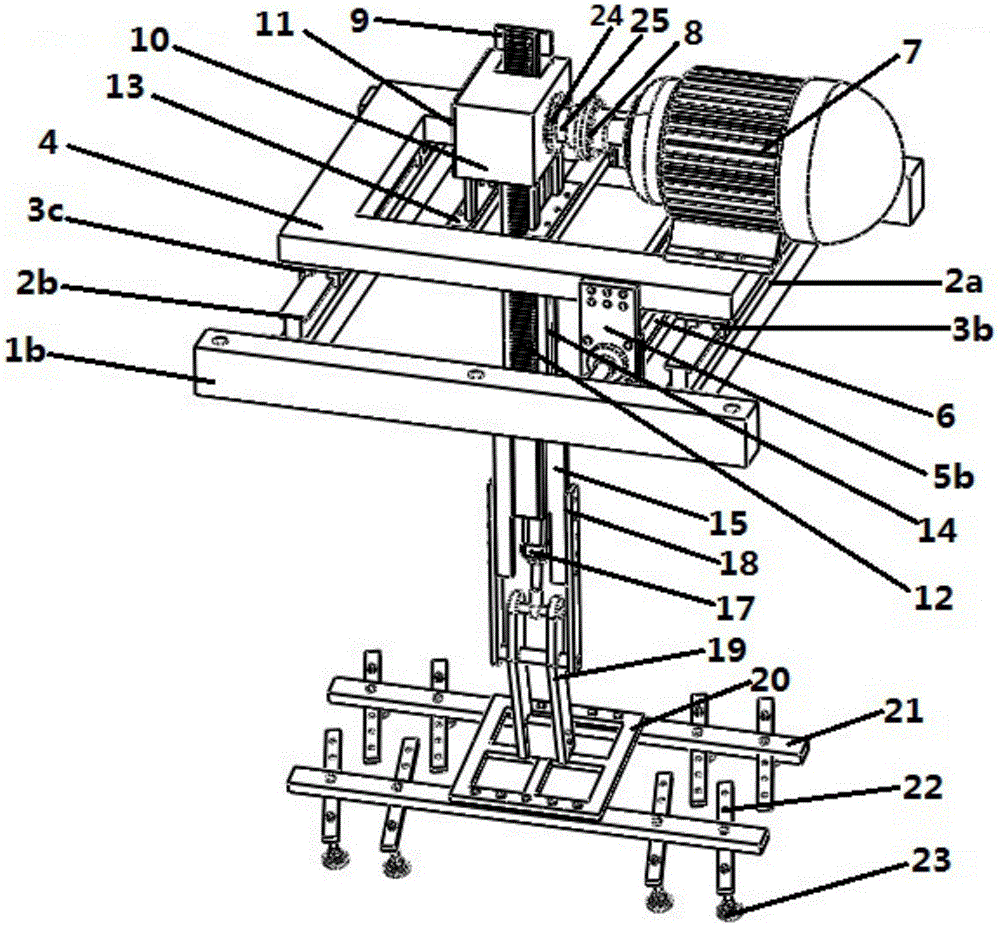

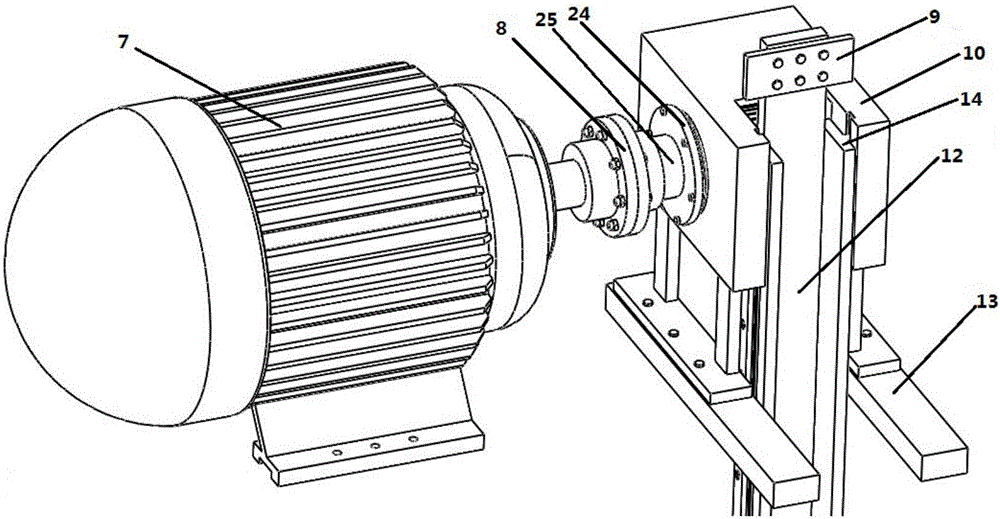

[0030] see figure 1 and figure 2 , an automatic boxing device comprising: a horizontal feed mechanism, a rack and pinion mechanism, a turning mechanism and an air sucker mechanism;

[0031] figure 1 and figure 2 As shown, the composition of the horizontal feed mechanism includes a beam-shaped front base 1a, a beam-shaped rear base 1b, a feed cylinder 6, a left feed guide rail 2a, a right feed guide rail 2b, and a left lower guide rail seat 3a and a left upper guide rail seat 3b. The left guide rail seat, the right guide rail seat formed by the upper right guide rail seat 3c and the right lower guide rail seat 3d, the back-shaped support 4 and the cylinder fixed plate formed by the cylinder tail end fixed plate 5a and the cylinder head fixed plate 5b;

[0032] A left feed guide rail 2a and a right feed guide rail 2b are arranged between the two ends of the beam-shaped front base 1a and the beam-shaped rear base 1b, thereby forming a rectangular seat; The right guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com