Method for cutting groove of U-rib steel plate by plasma cutting torches at double variable angles for one time

A plasma, variable angle technology, applied in plasma welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of many processing procedures, poor processing quality of U-rib steel plate grooves, etc., to achieve full automation and fully automated operation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of double-variable-angle plasma cutting torch provided by the present invention cuts the method of U-ribbed steel plate bevel once, operates according to the following steps:

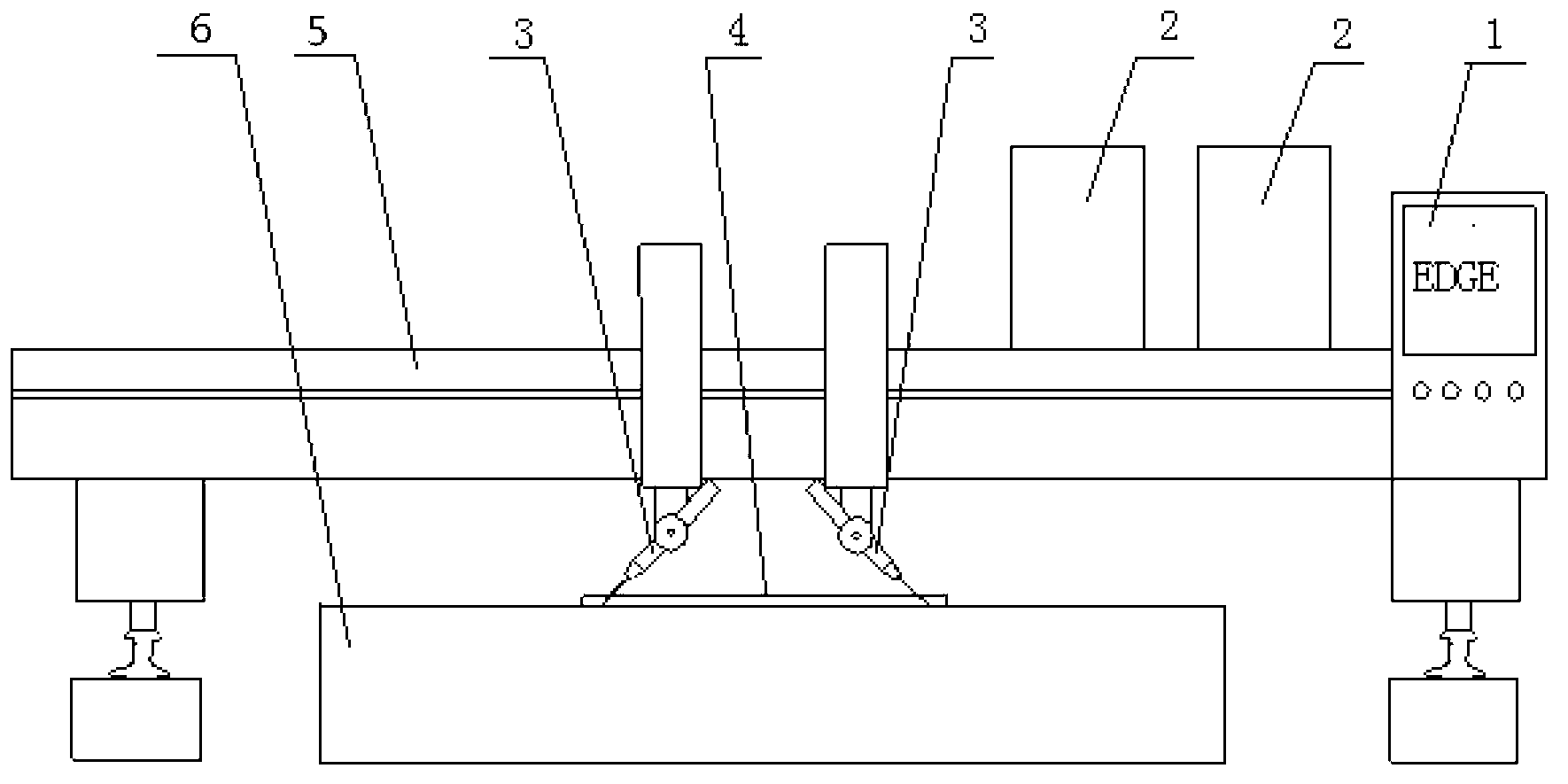

[0028] ⑴ Choose a HPR260 plasma CNC cutting machine, such as figure 1 As shown, on the plasma CNC cutting machine body 5, two sets of max105 plasma power sources 2 and two sets of plasma cutting torches 3 that can deflect angles are installed; the two plasma cutting torches 3 are equipped with cutting torch initial height positioners , THC cutting torch arc voltage adjustment system and EDGE CNC system PLC programmable system.

[0029] (2) Fix the U-ribbed steel plate 4 to be cut on the cutting table 6 .

[0030] (3) Align the two plasma cutting torches 3 with the edge of the U rib steel plate 4 to be cut, adjust the lateral distance of the two plasma cutting torches 3, adjust the deflection angle of the two plasma cutting torches 3, and set the initial positioning of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com