Soluble coaxial-cone multi-layer microneedle, microneedle array and preparation method of microneedle

A microneedle array, soluble technology, applied in other medical devices, drug devices, etc., can solve problems such as inability to realize drugs, and achieve the effect of preventing inactivation and avoiding mutual reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned soluble coaxial cone multilayer microneedle array comprises the following steps:

[0047] (1) Using CNC micro-milling technology to prepare the central layer and the outer layer master mold, and then use PDMS to replicate the center layer and the outer layer. The shape of the center layer master mold is conical or conical cylindrical, and the outer layer master mold The shape of the mold is conical, and the material of the main mold is brass, aluminum or alloy;

[0048] (2) Using the central layer main mold and female mold obtained in step (1) to prepare the central layer of the soluble coaxial cone multilayer microneedles by one-step method or step-by-step method;

[0049] (3) Use the outer layer master mold and female mold obtained in step (1) to wrap one or more layers of The outer layer, that is, the soluble coaxial cone multilayer microneedles.

[0050] Using CNC micro-milling technology for precision structure moldin...

Embodiment 1

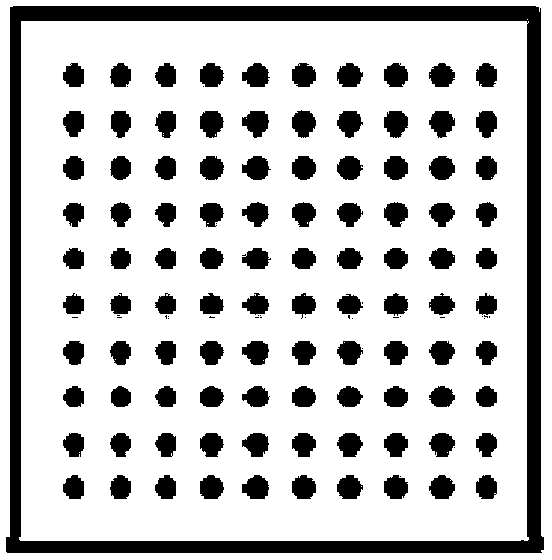

[0058] Mold fabrication: Fabricate a 10 × 10 rectangular microneedle array master mold using micromilling technology (see figure 1 ), master mode A (see Figure 12 ): The microneedles are conical, with a base diameter of 300 μm, a length of 800 μm, and an interaxial distance of 1 mm; master mold B (see Figure 13 ): The microneedles are conical, with a base diameter of 225 μm, a length of 600 μm, and an interaxial distance of 1 mm; master mold C (see Figure 14 ): Conical shape, bottom diameter 300μm, top diameter 225μm, length 200μm, axial distance 1mm. main form D (see Figure 15 ): The microneedle is conical cylindrical, the diameter of the bottom cylindrical part is 125 μm, the length is 400 μm, the diameter of the bottom of the top conical part is 125 μm, the length is 200 μm, and the distance between the axes is 1 mm. Replicate PDMS female molds a, b, c and d using the master mold (see Figure 16-19 ).

Embodiment 2

[0060] Methylene blue dyed soluble coaxial cone multilayer microneedles

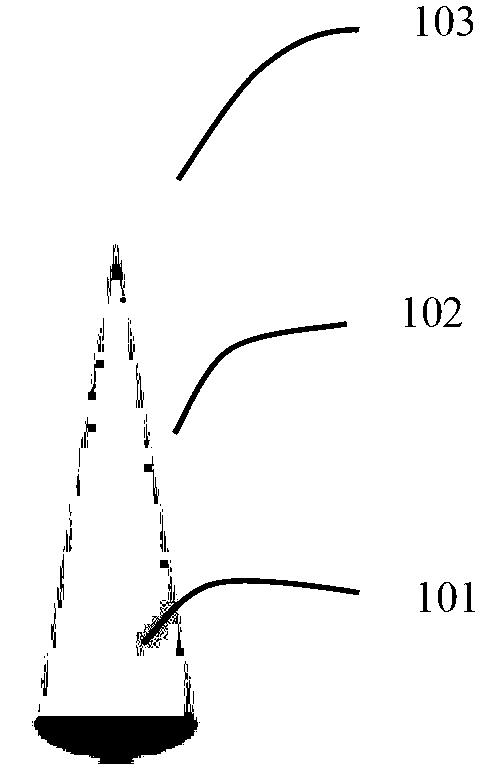

[0061] In this embodiment, a dissolvable conical multi-layer microneedle array containing 100 microneedles, wherein the appearance of the microneedles is cone-shaped, the external dimensions are: the height is 800 μm, the diameter of the bottom surface is 300 μm, and its internal structure includes conical A central layer and an outer layer wrapped around the central layer.

[0062] The preparation method of the above-mentioned soluble coaxial cone multilayer microneedle array comprises the following steps:

[0063] (1) Dissolve 40 mg of Carbopol in 200 μL of deionized water under stirring at 800 rpm, adjust the pH to 6 with 10 M NaOH, and pour the formed uniform glue into the female mold b (see Figure 17 ), centrifuged at 4000rpm for 20min, dried in an oven at 45°C for 8 hours, and demolded to obtain a conical central layer 101 arranged on the base layer;

[0064] (2) Dissolve 1 mg of methylene blue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com