Brushcutter

A technology of cluster cutting machine and engine, which is applied in the field of improvement of cooling mechanism, can solve problems such as heating, deformation, and high temperature of centrifugal clutch, and achieve the effect of avoiding the structure from becoming complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

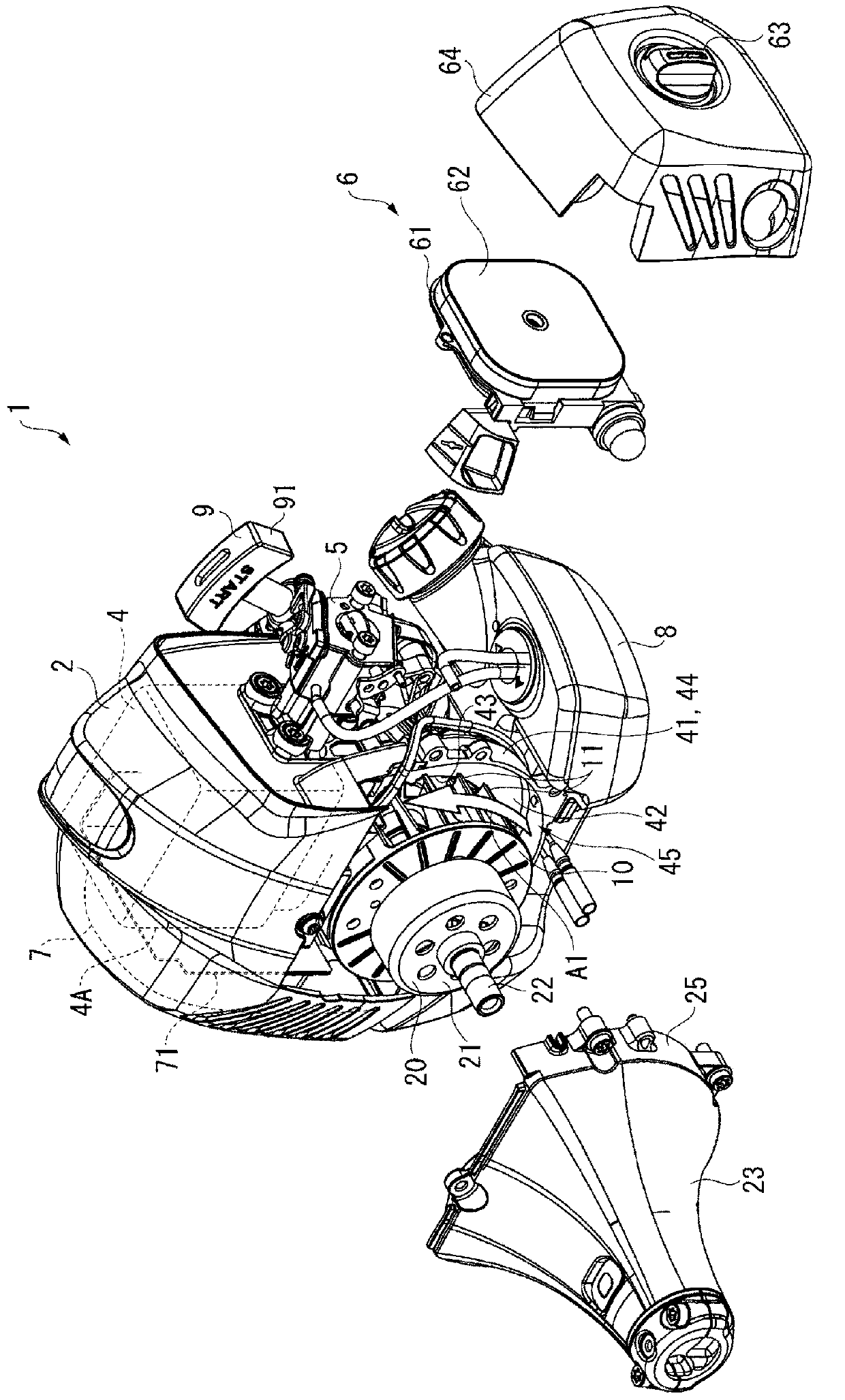

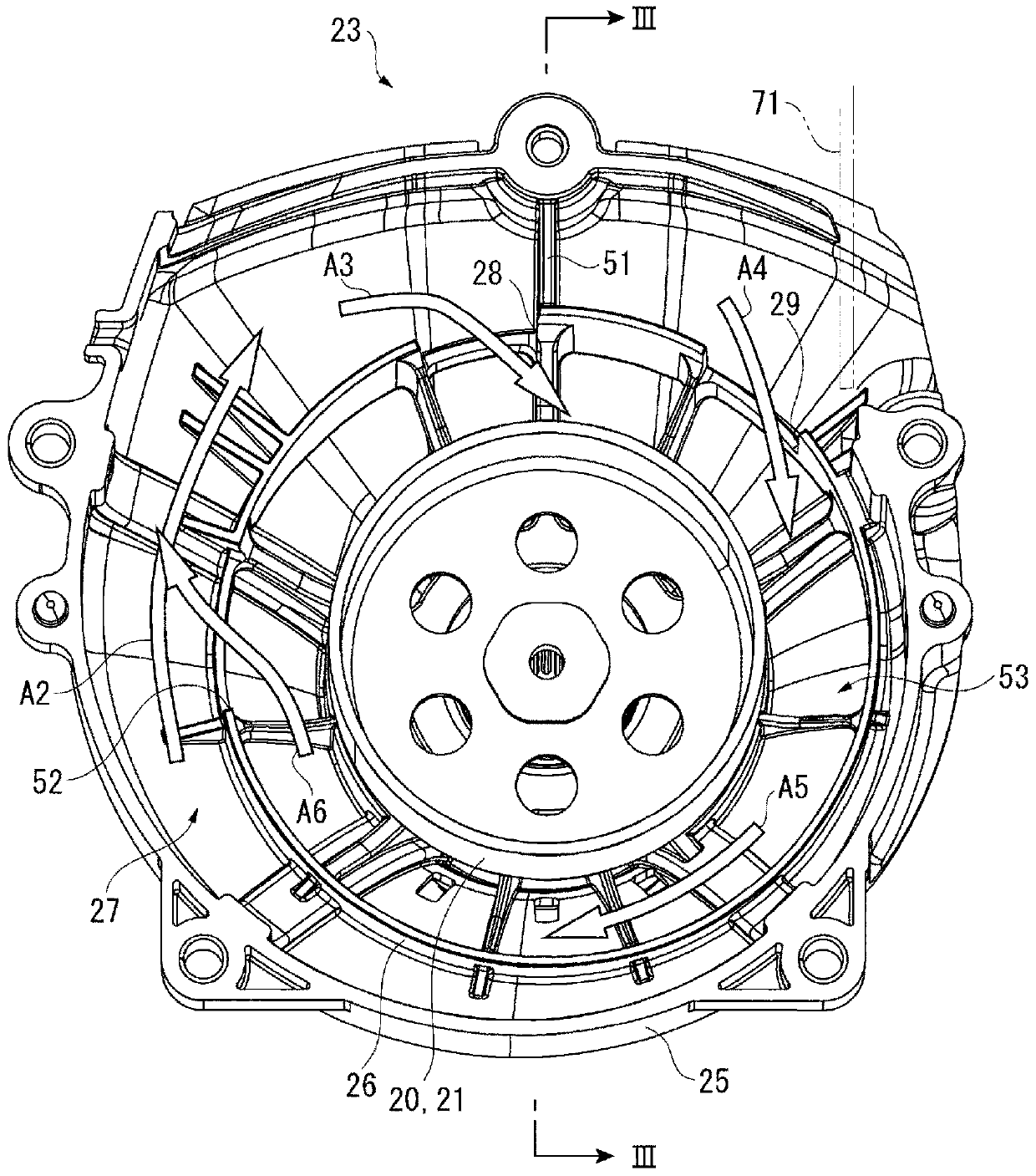

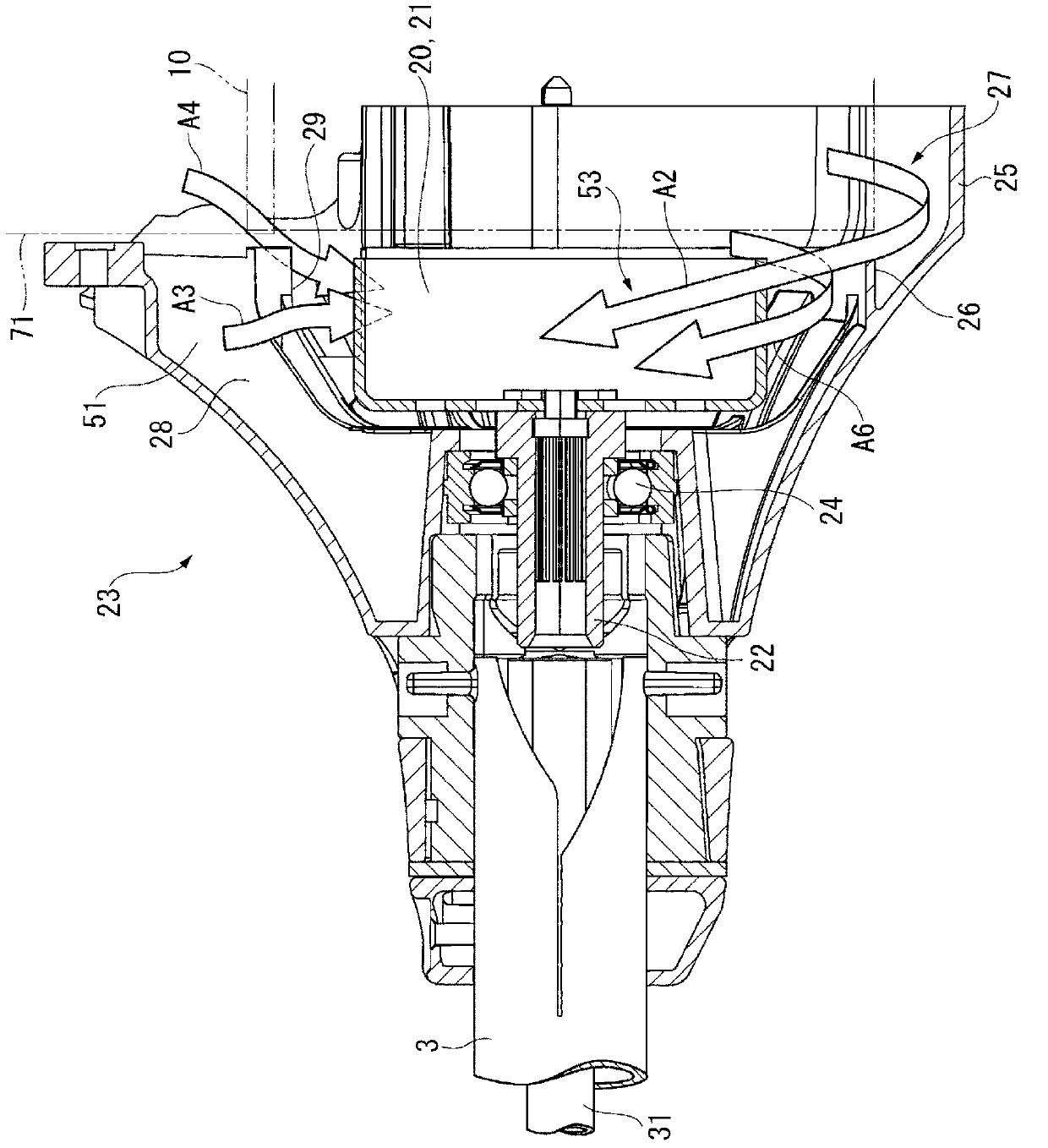

[0032] Such as Figures 1 to 3 As shown, the brush cutter 1 comprises: a main body 2 including as a main component a single cylinder two-stroke engine 4; an operating rod 3 having a base end connected to the main body 2; attachments such as blade saws and nylon cutters , attached to the other end of the operating rod 3 ; and a handle, attached to a part of the operating rod 3 . Engine 4 may be a four-stroke engine.

[0033] Inside the main body 2 , a carburetor 5 is attached to the engine 4 and an air cleaner 6 is attached to the carburetor 5 . An exhaust muffler 7 is attached to the engine 4 at a side opposite to the carburetor 5 . A fuel tank 8 is attached to the underside of the engine 4 . The carburetor 5 draws fuel from a fuel tank 8 .

[0034] The air cleaner 6 includes: a filter case 61 screwed to the carburetor 5; a sponge-like member 62 accommodated in the filter case 61; and a filter cover 64, It is attached to the filter case 61 by operating screws 63 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com