Aluminum air fuel cell system

A fuel cell system, aluminum-air technology, applied in fuel cell additives, fuel cell components, fuel cell-type half-cells and primary cell-type half-cells, etc., can solve the problem of reducing battery energy output efficiency, electrolyte solution Evaporation increases, electrolyte temperature rises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

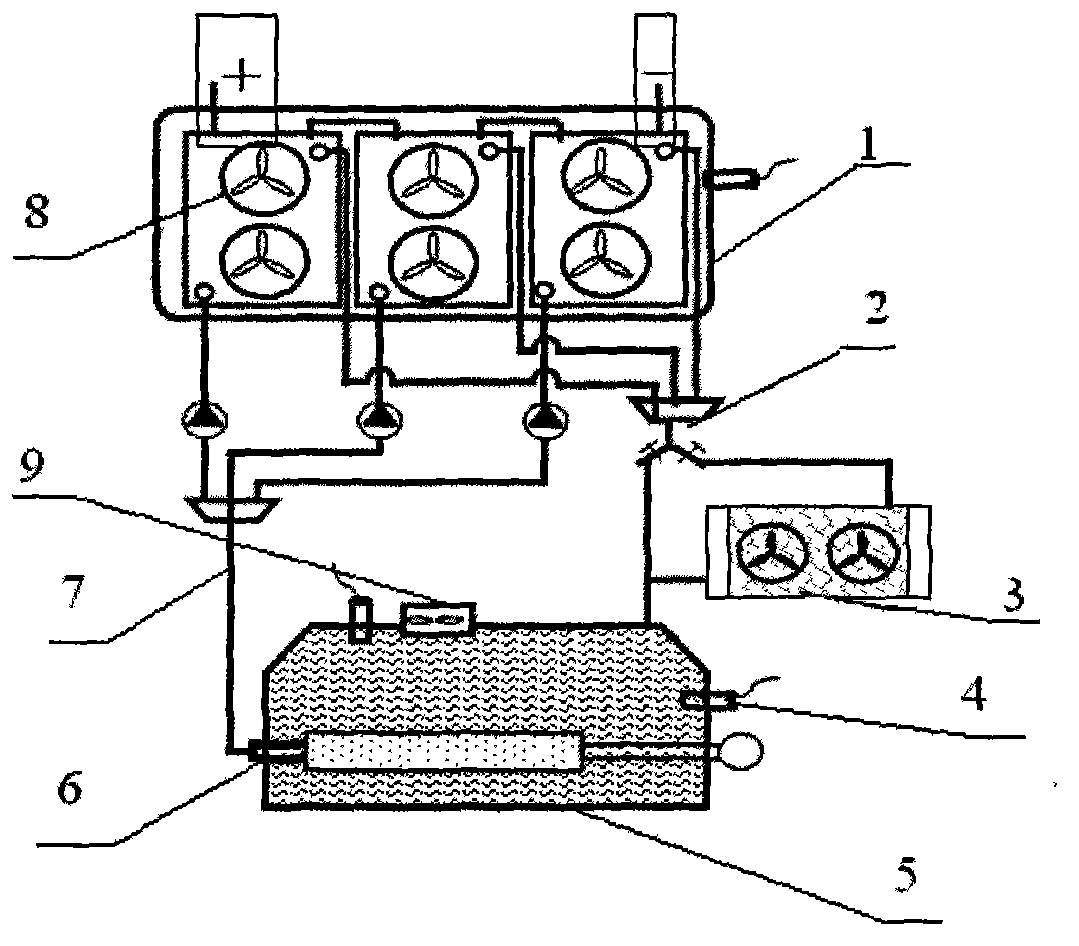

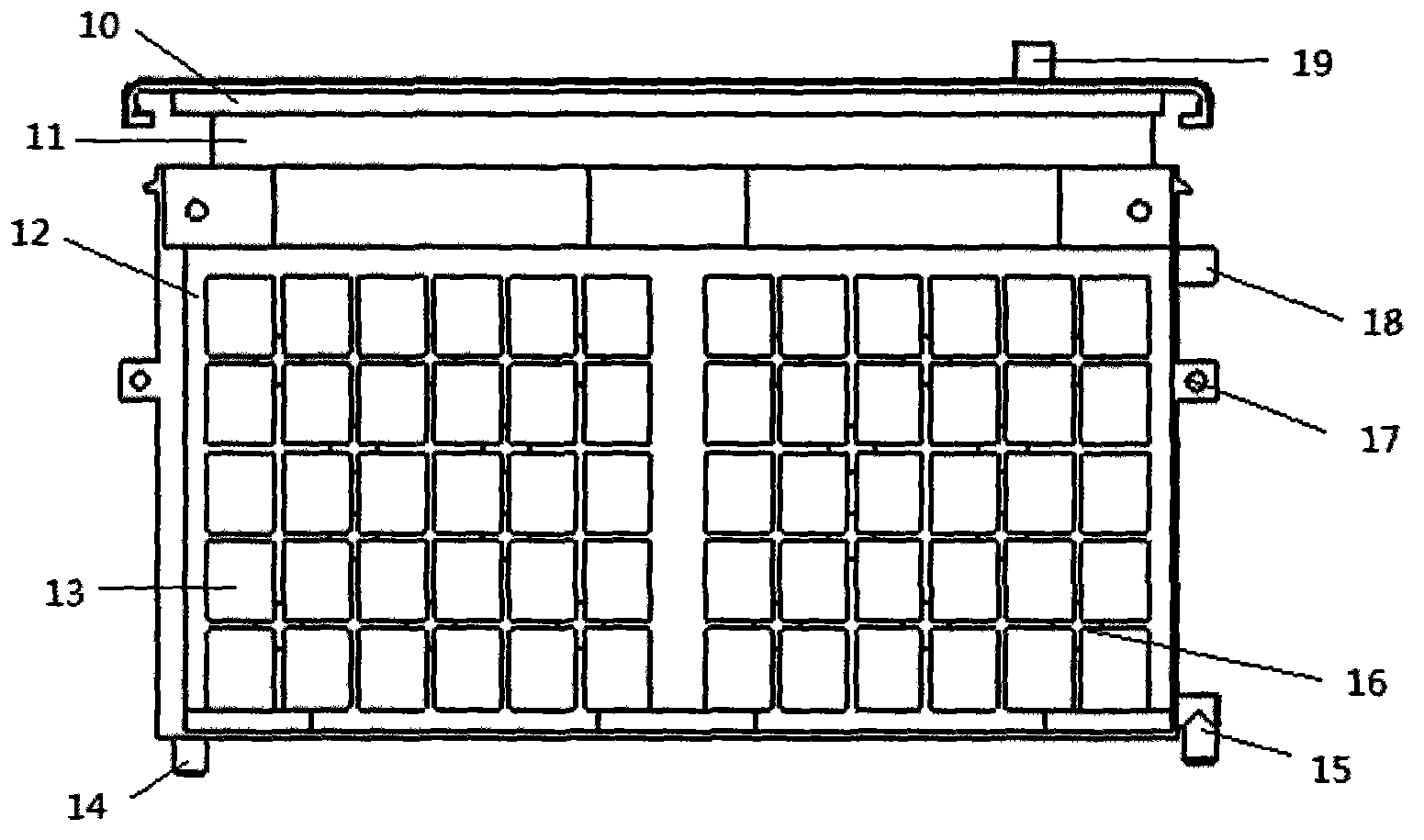

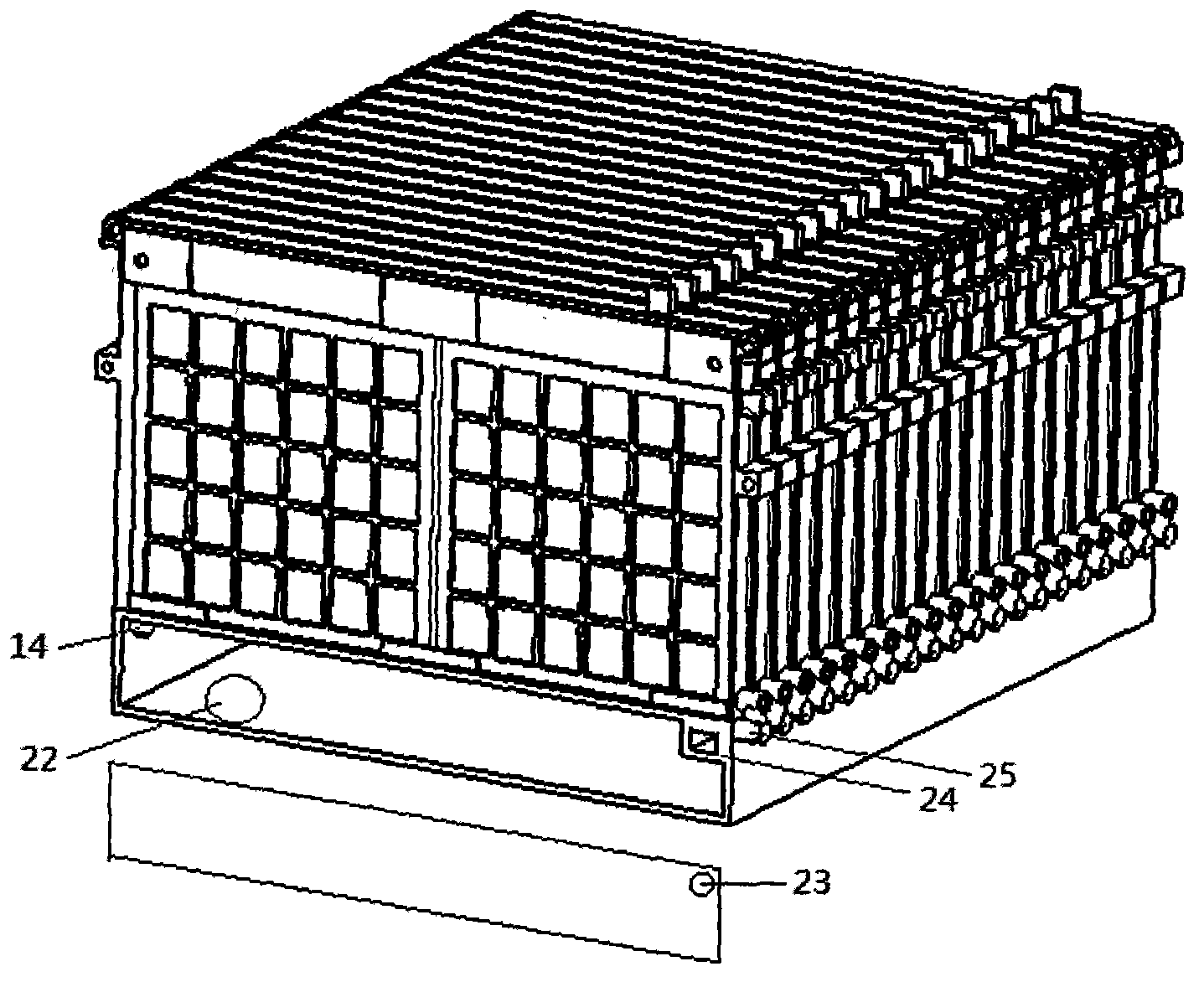

[0057] An aluminum-air fuel cell system such as figure 1 As shown, it includes an electrolyte tank 5, a battery stack 1 and a ventilation system 8; the electrolyte tank 5 is located under the battery stack 1, and the ventilation system 8 is placed on the side of the gap between the single cells of the battery stack; it also includes an electrolyte filling system 7, Electrolyte liquid return system 2, hydrogen exhaust system 9, temperature measurement system 4, filter system 6 and heat dissipation system 3; electrolyte liquid filling system 7 communicates with each single cell pipeline of the battery stack 1 located on its upper part; electrolyte return system The liquid system 2 is located between the battery stack 1 and the electrolyte tank 5 and is connected to the pipes; the hydrogen exhaust system 9 is placed on the electrolyte tank 5; the temperature measurement system 4 is located in different parts of the battery stack 1 and the electrolyte tank 5 Middle; the filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com