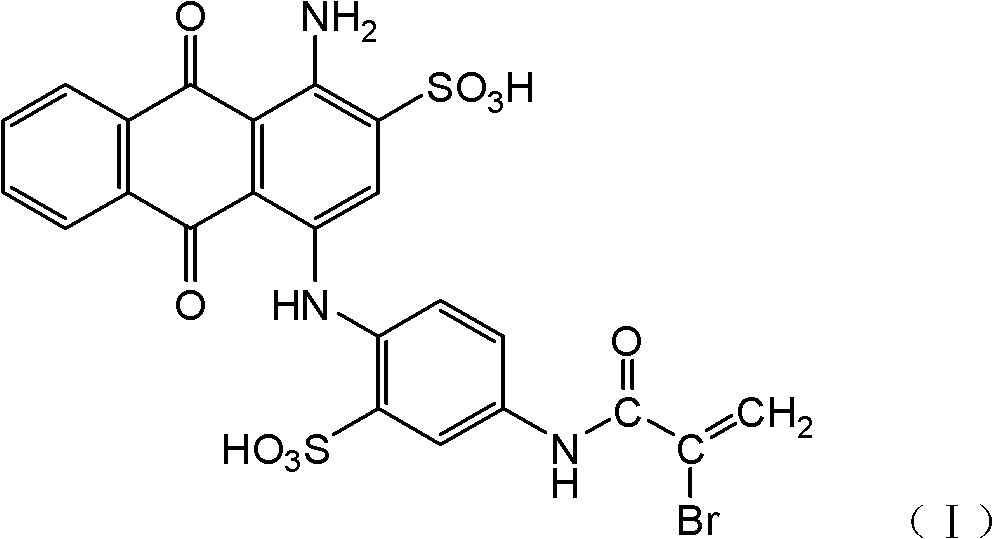

Method for preparing reactive brilliant blue 3G for wool

A technology for reactive brilliant blue and wool, applied in reactive dyes, chemical instruments and methods, dyeing methods, etc., can solve the problems of high labor intensity, long reaction period, environmental pollution, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

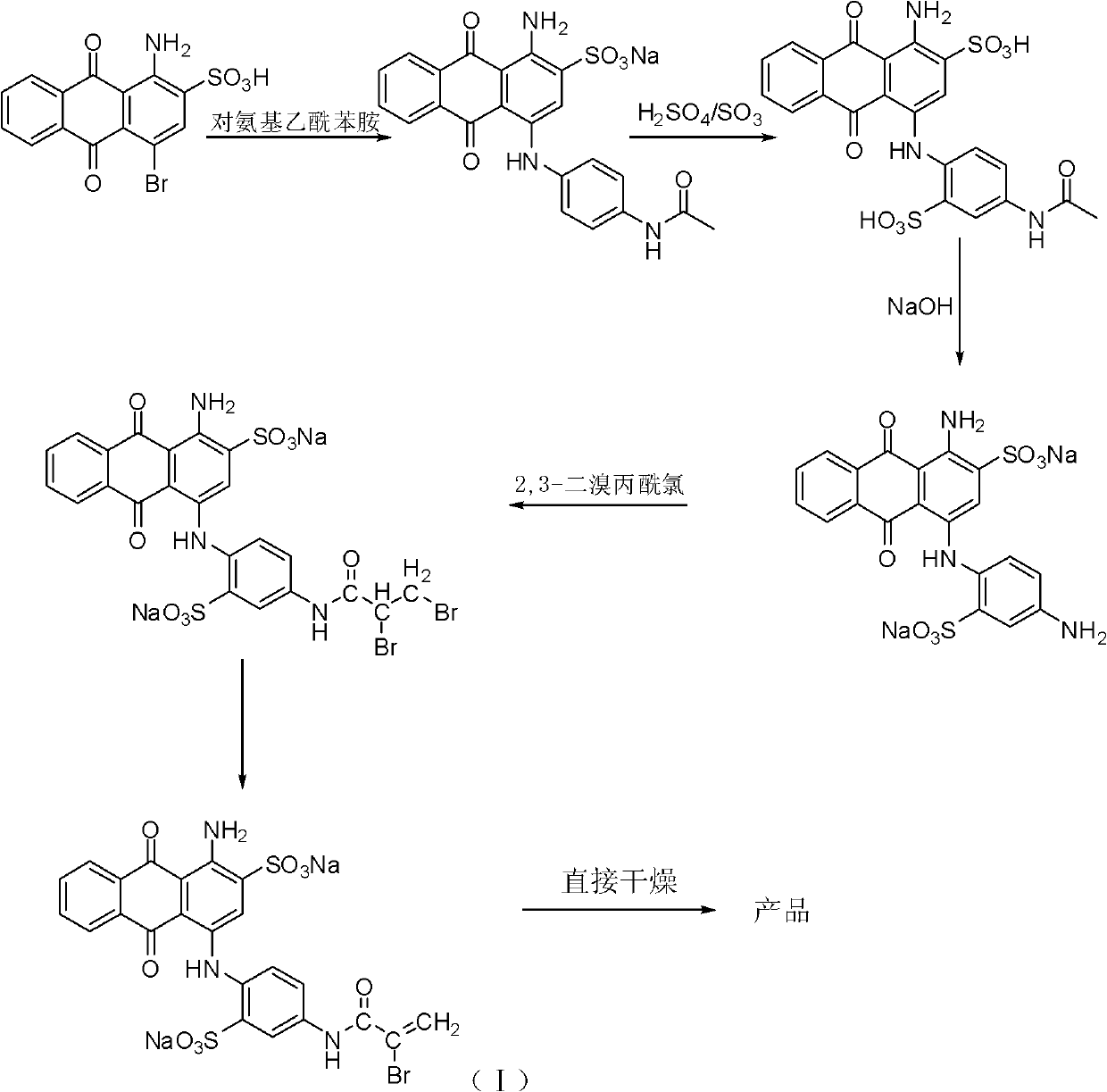

Method used

Image

Examples

Embodiment 1

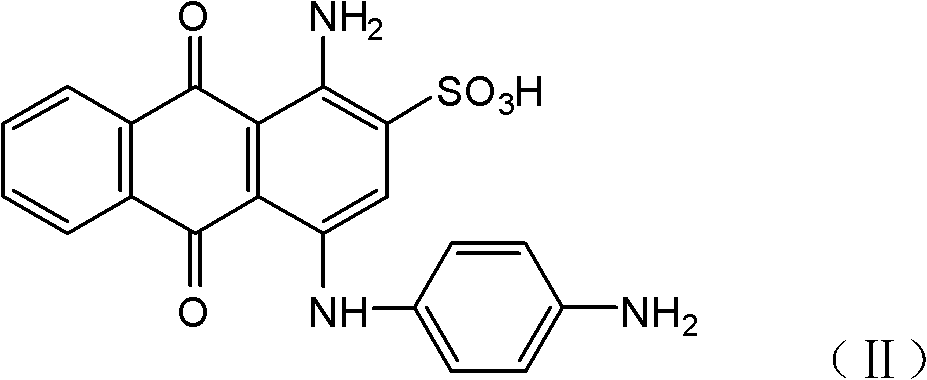

[0026] a. Condensation reaction of bromoacid and p-aminoacetanilide

[0027]

[0028] Add 1.68 parts of sodium bicarbonate, 1.06 parts of sodium carbonate and 40 parts of water into a three-necked reaction flask, and stir to dissolve. After completely dissolving, add 4.04 parts of bromonic acid, 1.8 parts of p-aminoacetanilide, 0.125 parts of copper sulfate and 0.125 parts of stannous chloride in sequence, raise the temperature to 70-80°C, stir and react for 4 hours, and detect bromine by thin-layer chromatography or HPLC. Amino acid disappears and the reaction is complete. Cool down to room temperature and filter, mix the filter cake with 40 parts of water, adjust the pH to 1.5-2.0 with 30% hydrochloric acid, stir, filter at room temperature, and dry the filter cake to obtain 4.5 parts of condensate for future use.

[0029] b. Sulfonation reaction

[0030]

[0031] Add 20 parts of 8-10% fuming sulfuric acid into a dry three-necked reaction flask, cool down to 0-5°C in...

Embodiment 2

[0042] Repeat the operating process and process conditions described in Example 1, except that in the step (a) of Example 1, the addition of copper sulfate and tin protochloride is changed to 0.25 parts respectively, and finally 8.5 parts of active dyes for wool are obtained. Blue 3G.

Embodiment 3

[0044] Repeat the operating process and process conditions described in Example 1, except that in the step (a) of Example 1, the amount of p-aminoacetanilide added is changed to 1.5 parts, and 3.6 parts are obtained after the primary condensation filter cake is dried, and finally 7 parts of Reactive Brilliant Blue 3G is used for hair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com