Method for preparing nitrogen-doped porous carbon from heavy organic component in coal liquefaction residue

A technology of coal liquefaction residue and nitrogen doping, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., to achieve the effect of easy large-scale production, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

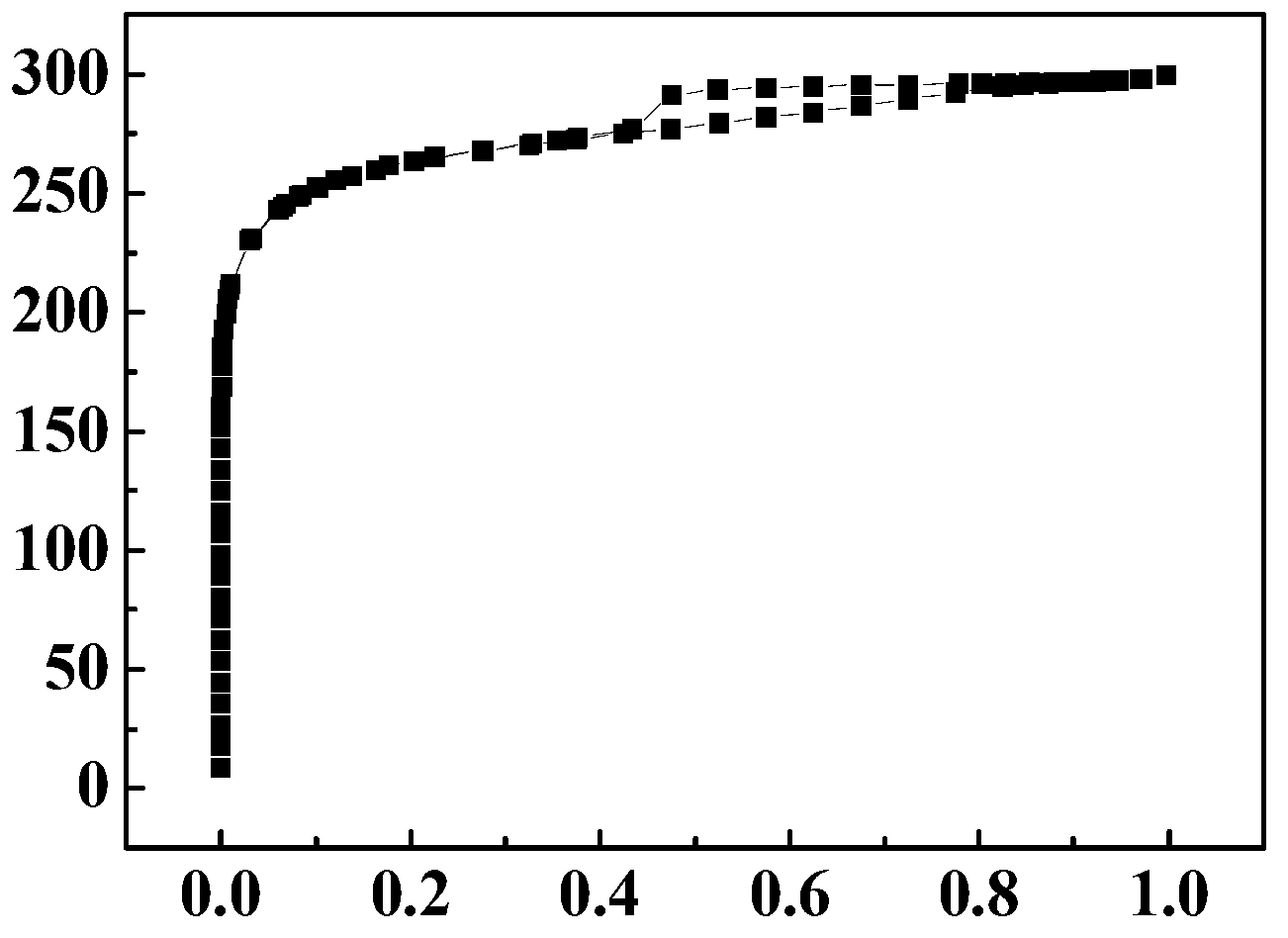

[0028] Mix the coal liquefaction residue with THF, extract and evaporate the solvent to obtain carbon-rich heavy organic components; mix the heavy organic components with dicyandiamide at a mass ratio of 1:0.5, and pre-oxidize in air at 300 °C for 1 h , to obtain a nitrogen-rich carbon source; the resulting nitrogen-rich carbon source is placed in a tube furnace, and the nitrogen-rich carbon source is 2 Under the atmosphere, the temperature was raised to 1000 °C at a rate of 10 °C / min, and the CO flow rate was switched to 50 mL / min. 2 , activated for 1 h, after completion, switch to 50mL / min N 2 , and cooled to room temperature to obtain nitrogen-doped porous carbon. The main properties of the porous carbon are shown in Table 1.

Embodiment 2

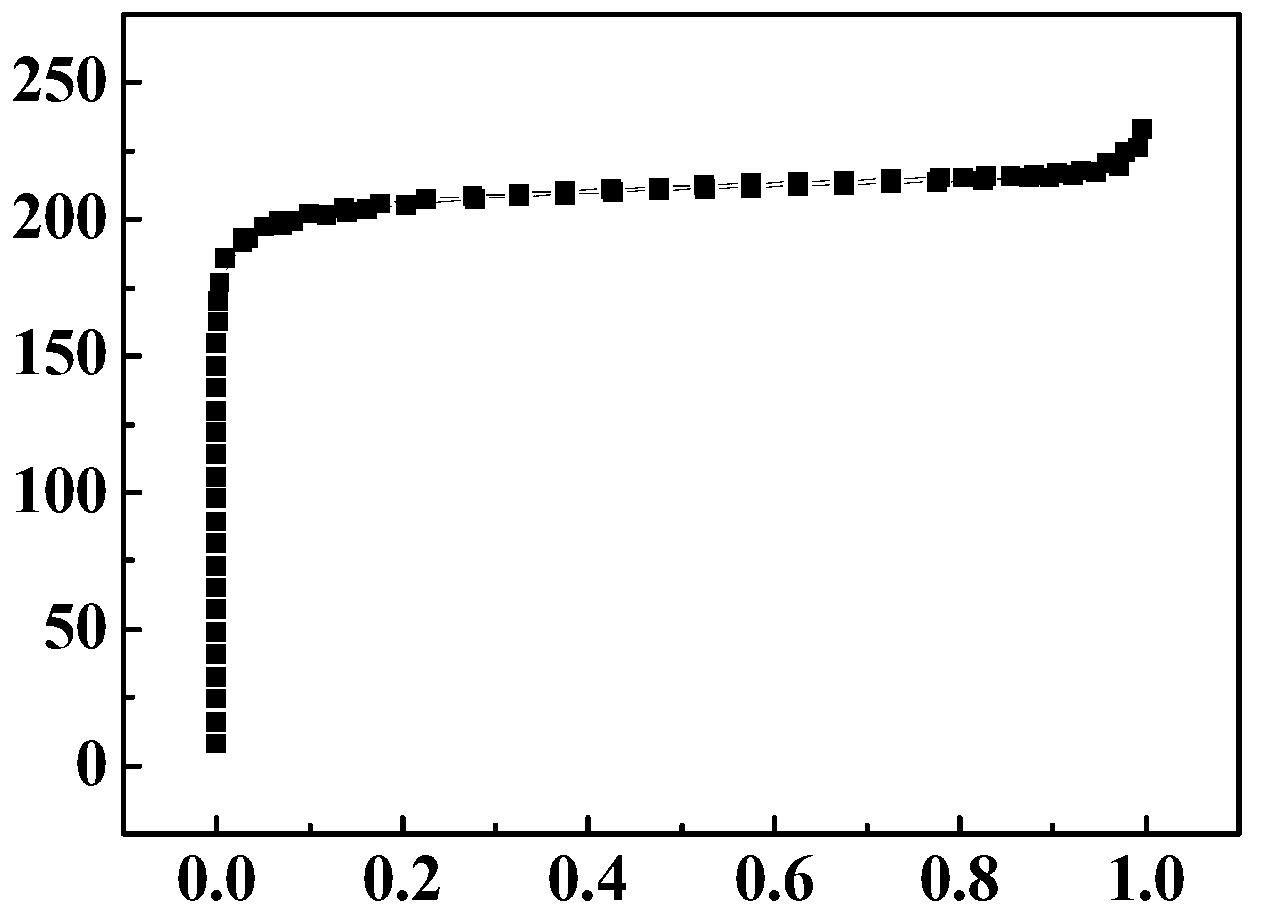

[0030] The coal liquefaction residue was mixed with tetrahydrofuran, and after extraction, the solvent was evaporated to obtain carbon-rich heavy organic components; the heavy organic components were mixed with ammonium chloride at a mass ratio of 1:5, and pre-oxidized in air at 150 °C for 10 h. The nitrogen-rich carbon source was obtained; the obtained nitrogen-rich carbon source was placed in a tube furnace, under an Ar atmosphere of 300 mL / min, the temperature was raised to 800 °C at a rate of 5 °C / min, and the flow rate was switched to 50 mL / min of H 2 O, activated for 10 h, after completion, switch to Ar at 300 mL / min, and cool to room temperature to obtain nitrogen-doped porous carbon. The main properties of the porous carbon are shown in Table 1.

Embodiment 3

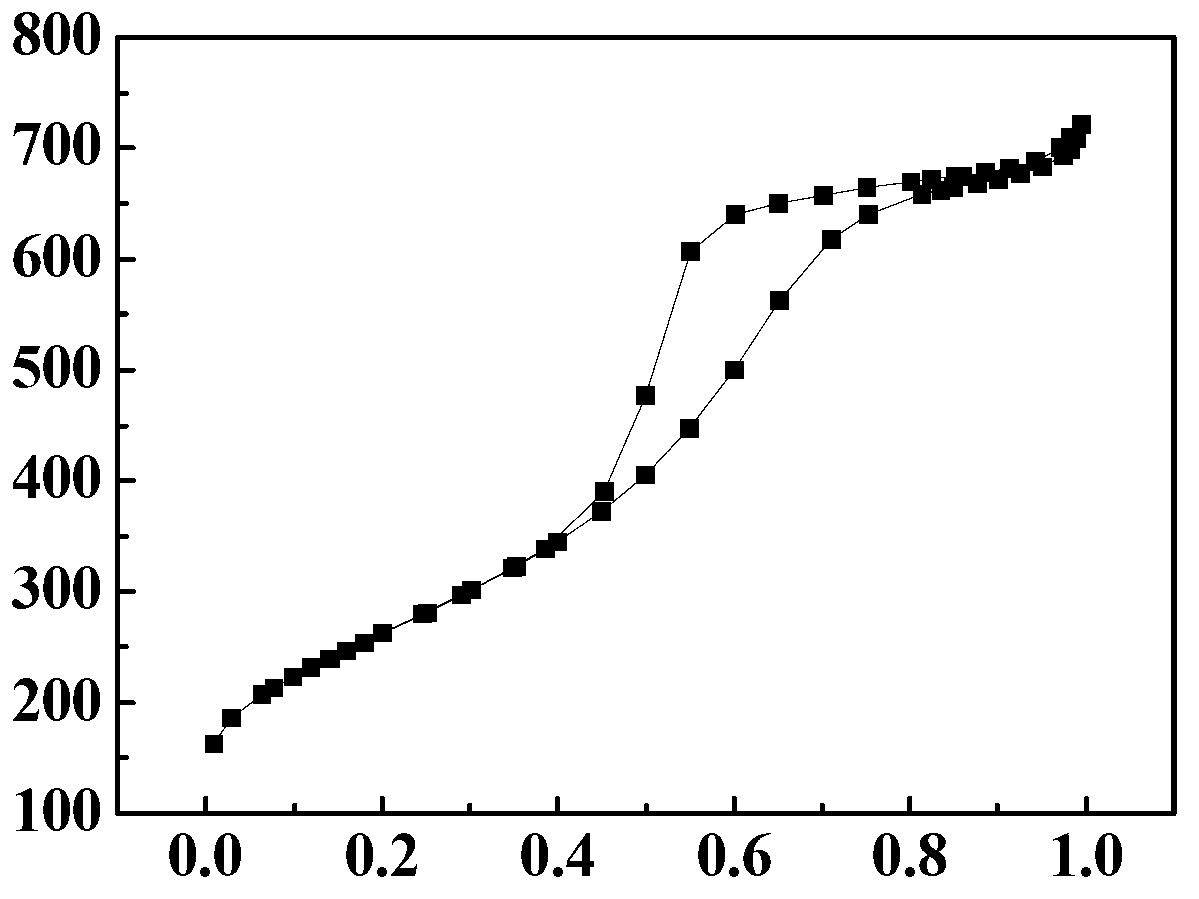

[0032] Mix coal liquefaction residue with tetrahydrofuran, extract and evaporate the solvent to obtain carbon-rich heavy organic components; mix heavy organic components with urea at a mass ratio of 1:2, pre-oxidize in air at 200 °C for 3 h, and obtain rich Nitrogen-carbon source; the obtained nitrogen-rich carbon source was placed in a tube furnace, and in a He atmosphere of 250 mL / min, the temperature was raised to 500 °C at a rate of 1 °C / min, and the flow rate was switched to O at 100 mL / min. 2 , activated for 2 h, after the completion, switch to 250 mL / min helium, and cool to room temperature to obtain nitrogen-doped porous carbon. The main properties of the porous carbon are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com