Paint bucket

A technology of paint buckets and nozzles, applied in the field of paint buckets, can solve the problems of difficult scrubbing, dripping, waste, etc., and achieve the effect of easy control, convenient storage and transportation, and not easy to splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

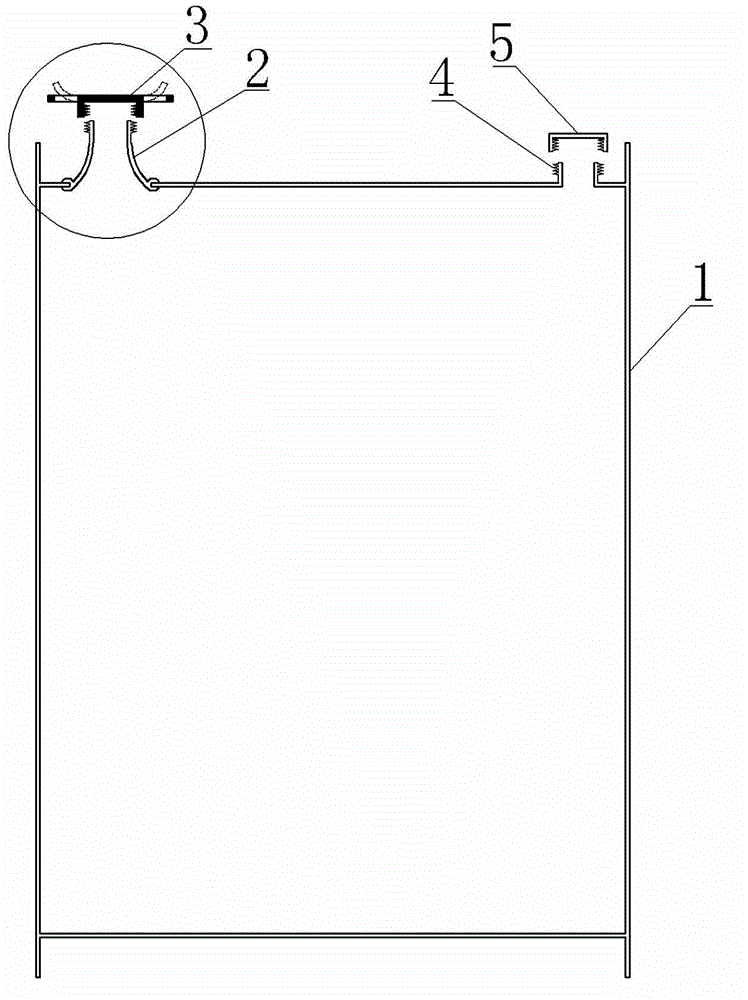

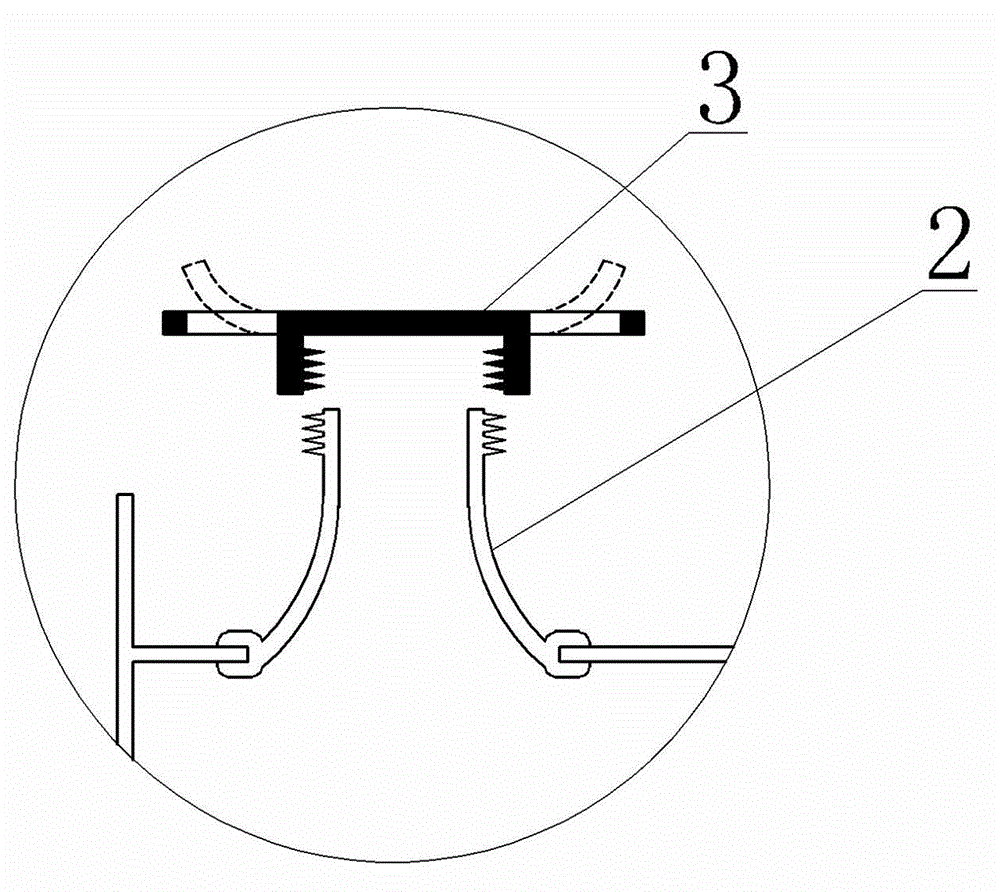

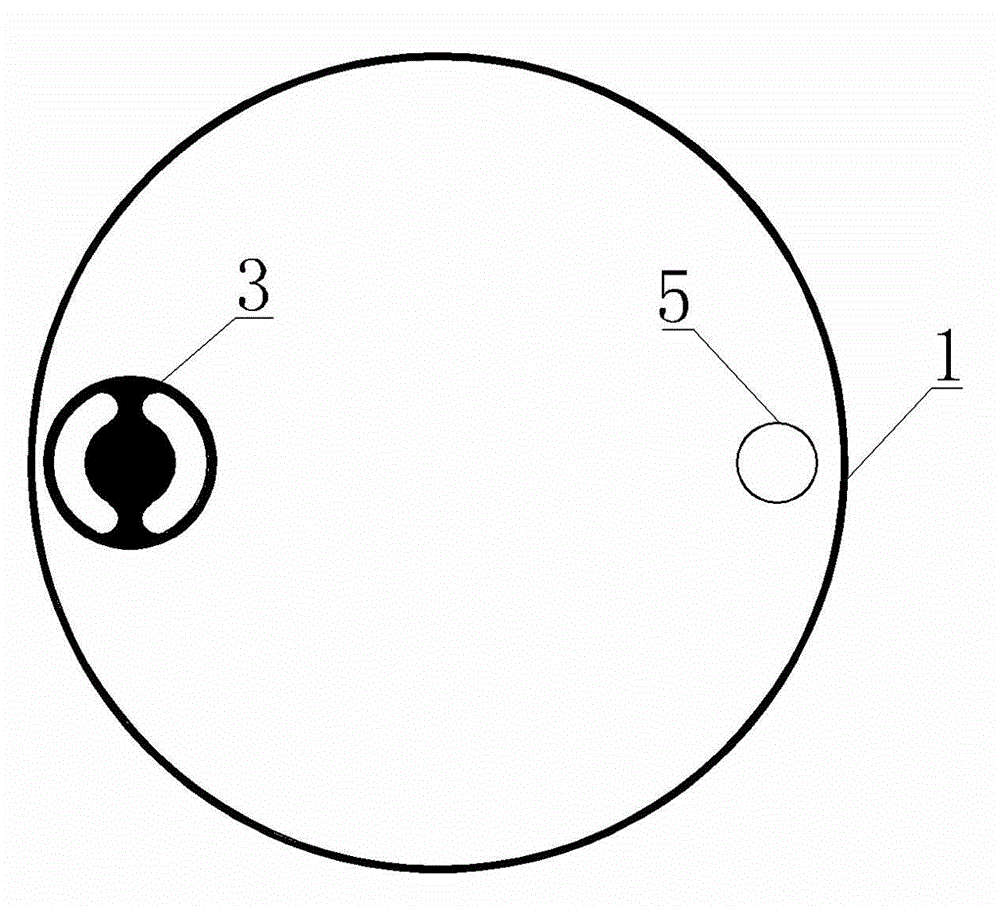

[0019] Such as figure 1 , figure 2 and image 3 As shown, a paint bucket is mainly composed of a barrel body 1, an oil nozzle 2, and an oil cap 3, the oil nozzle 2 is arranged on the top wall of the barrel body, the oil nozzle 2 is made of a deformable soft material, and the oil cap 3 is covered on the oil nozzle 2; Also be provided with gas nozzle 4 on barrel body, be provided with gas cap 5 on gas nozzle; When pouring oil, unscrew oil cap 3, unscrew or unscrew gas cap 5, make air can enter paint bucket by gas nozzle. In the process of pouring oil, air is replenished into the barrel body 1 from the air nozzle 4, so that the amount of painted paint remains stable, easy to control, and does not form splashes.

[0020] The oil nozzle 2 is arranged on the top wall of the barrel body 1, and the oil nozzle 2 is made of a deformable soft material, and the soft material is usually polyethylene.

[0021] When upward pulling force is exerted on the oil nozzle 2, the oil nozzle 2 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com