Preparation method of glass-reinforced plastic, and glass-reinforced plastic antenna housing and preparation method thereof

A glass fiber reinforced plastic radome and glass fiber reinforced plastic technology are applied in the field of metamaterials, which can solve the problems of high dielectric constant and loss of glass fiber reinforced plastic, and can not meet the performance requirements in the electromagnetic field, and achieve the effects of improving mechanical properties, improving interface bonding force, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

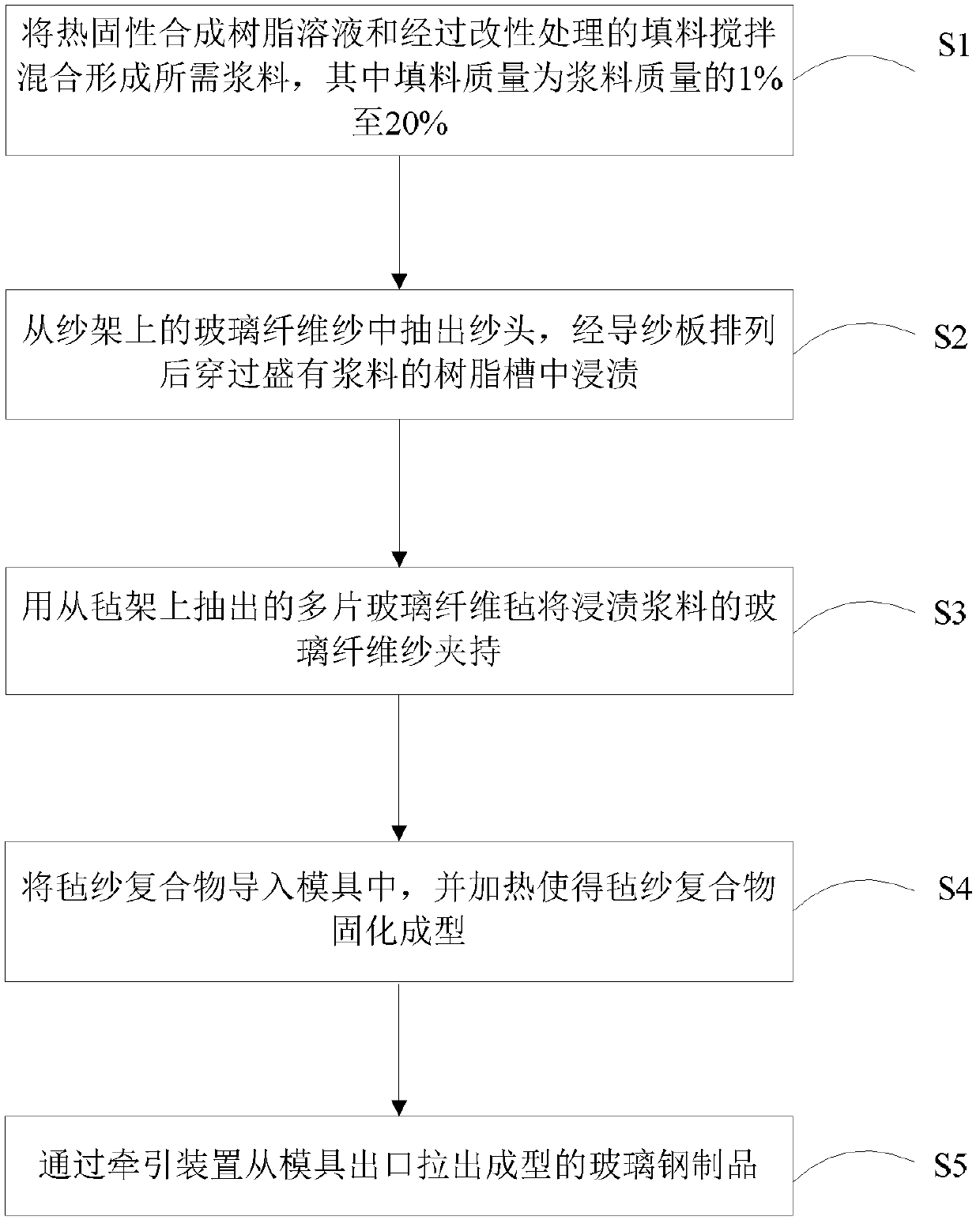

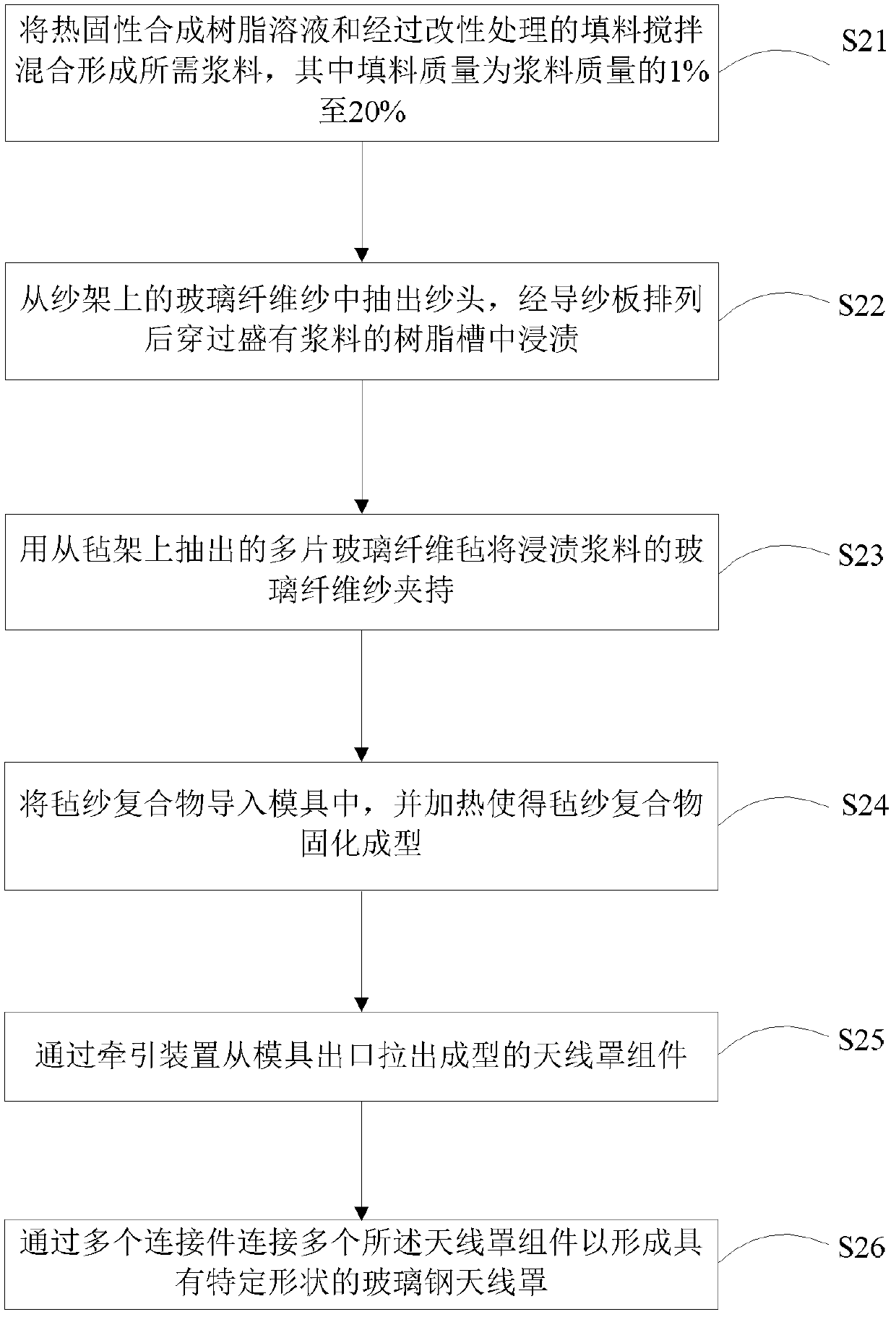

[0026] figure 1 It is a process flow chart of the preparation method of FRP of the present invention. The preparation method of FRP comprises the steps:

[0027] S1: Stir and mix the thermosetting synthetic resin solution and the modified filler to form the required slurry, and put the slurry into a resin tank, wherein the mass of the filler is 1% to 20% of the mass of the slurry;

[0028] The thermosetting synthetic resin solution may include any one or more of unsaturated polyester resins, epoxy resins, phenolic resins, furan resins, and vinyl ester resins. The thermosetting synthetic resin solution can be added with other auxiliary materials such as initiators, accelerators, flame retardants, solvents, etc. as the case may be.

[0029] Different resin types and dosages can choose different curing systems. In this embodiment, the thermosetting synthetic resin solution is prepared from unsaturated polyester resin, and an imidazole-based curing system or an amine-based curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com