Rotating welding electrode structure of pipe pile seam welder

A technology of spin welding and electrode structure, applied in the direction of electrode characteristics, resistance electrode seat, etc., can solve the problems of welding current variation, welding circuit overheating, electrode pressure instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

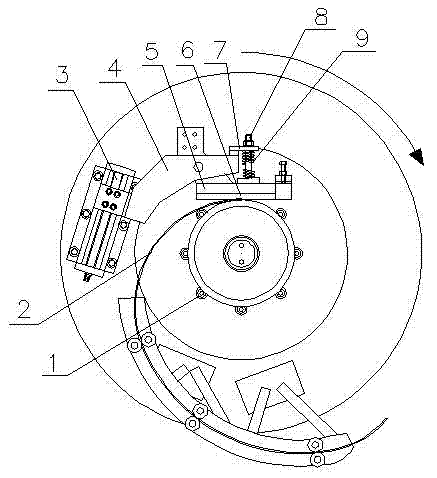

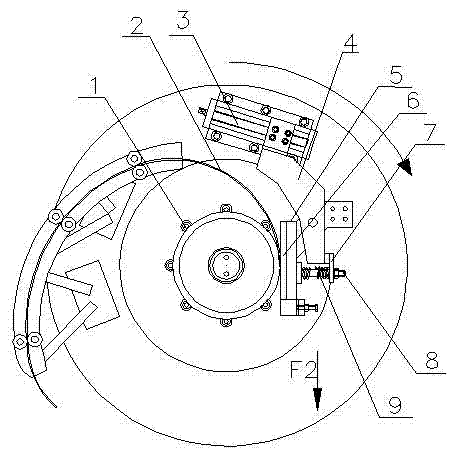

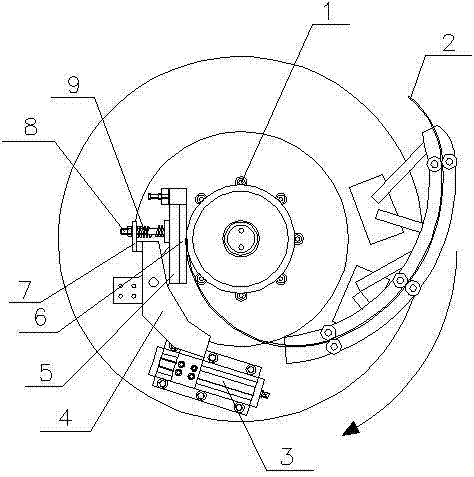

[0020] see Figure 5 In the rotary welding electrode structure of the pipe pile seam welding machine described in this embodiment, the support plate 4 is composed of a long support plate and a short support plate to form a splint type support structure, and is fixedly connected with the wire steel adjustment mechanism 3 through the long support plate, and the length A pendulum shaft 11 and an eccentric shaft 15 are assembled between the support plate and the short support plate; the conductive electrode plate 5 and the welding electrode plate 6 are assembled together by a positioning sleeve 10 and installed on a reinforcement plate 17 fixed to the pendulum shaft 11 Above; the spring positioning assembly is composed of a spring limiting plate 7, a spring positioning rod 8, a spring 9 and a spring adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com