Supergravity hydrate synthesis device

A synthesis device and hydrate technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as unsatisfactory effects, and achieve the effects of increasing synthesis efficiency, low energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

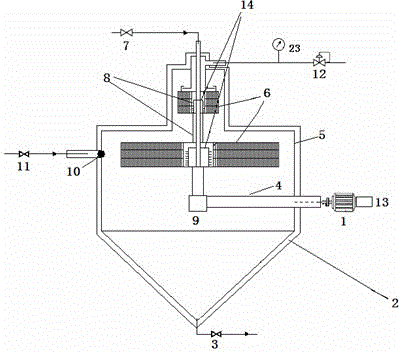

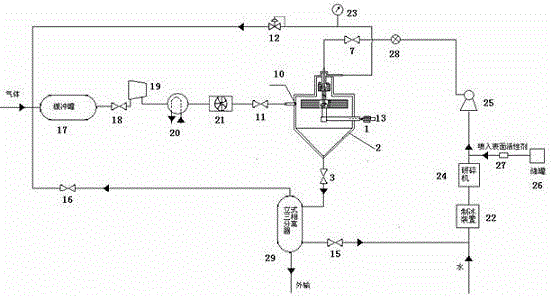

[0043] The device of the present invention consists of stop valve 3, first one-way liquid valve 7, second one-way gas valve 11, pressure regulating valve 12, second one-way liquid valve 15, the third one-way gas valve 16, gas buffer tank 17 , the first one-way air valve 18, compressor 19, condenser 20, turbine flow meter 21, ice making device 22, pressure gauge 23, grinder 24, slurry pump 25, surfactant storage tank 26, Laval It consists of a spray valve 27, a mass flow meter 28, a vertical three-phase separator 29 and a supergravity reactor.

[0044] Design of hypergravity reaction device

[0045] The supergravity reactor includes a casing 5, upper and lower rotors 6, a liquid distributor 14, a motor 1 with a frequency conversion speed regulator 13, a rotating shaft 4, a central liquid inlet pipe 8, a steering mechanism 9, and a refrigeration de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com