Fan blade suitable for axial flow fan with front motor frame

A technology for axial flow fans and motor racks, which is applied to parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc. It can solve problems such as large-scale vortices, improve flow conditions, and reduce turbulent noise , The effect of the expansion of the forward pressure gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

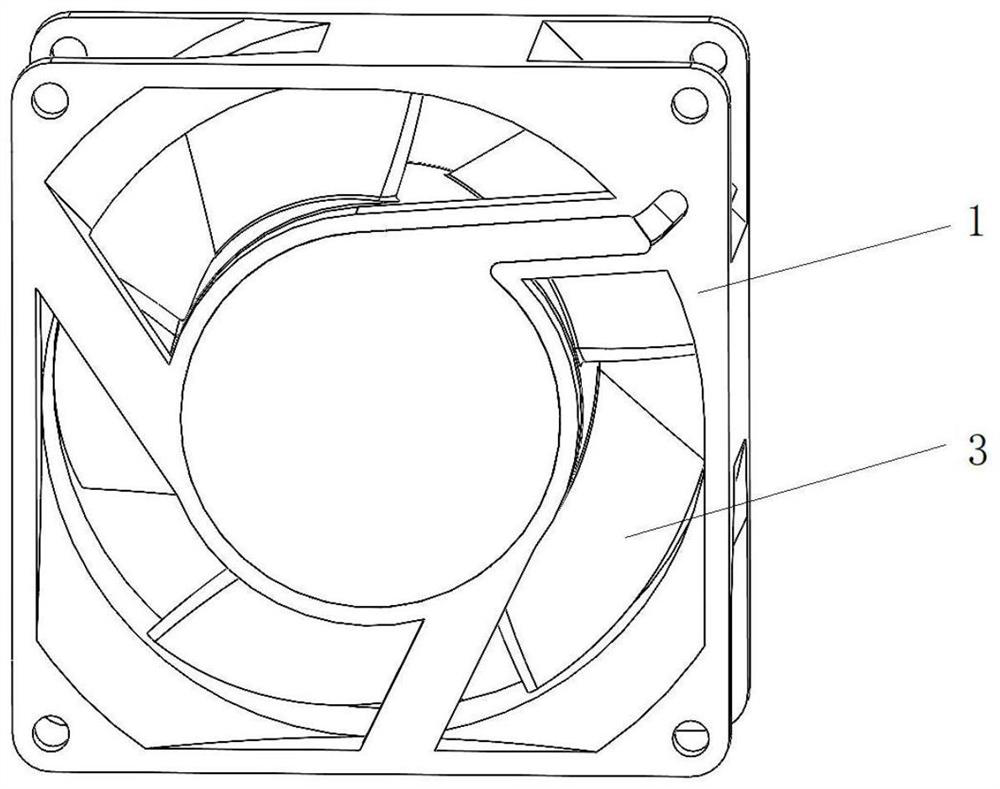

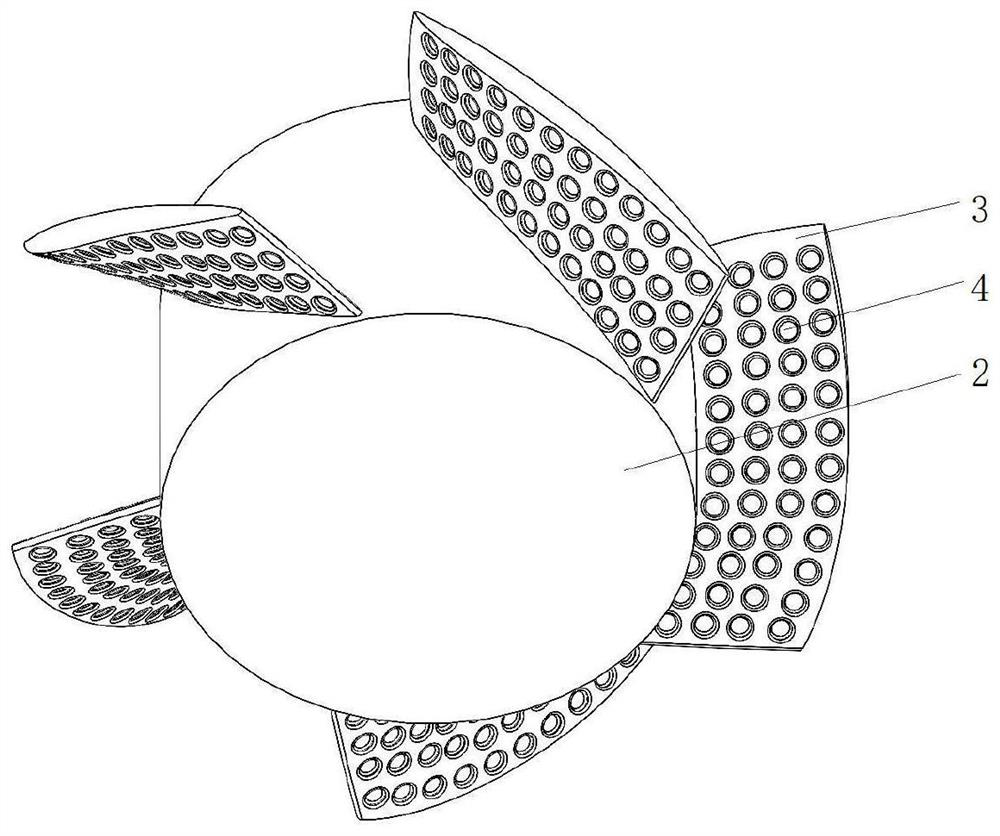

[0043] See figure 2 , the fan blade of this embodiment is suitable for an axial flow fan installed in front of the motor frame, including a tire 2 and a plurality of three-dimensional twisted blades 3 uniformly distributed on the outer peripheral surface of the tire. The windward surface of the blade 3 is provided with A plurality of dimples 4 arranged in a matrix, and each row of dimples 4 are arranged along the flow direction at the same span height, the flow spacing S of each row of dimples 4 is equal, and the span spacing C between rows equal.

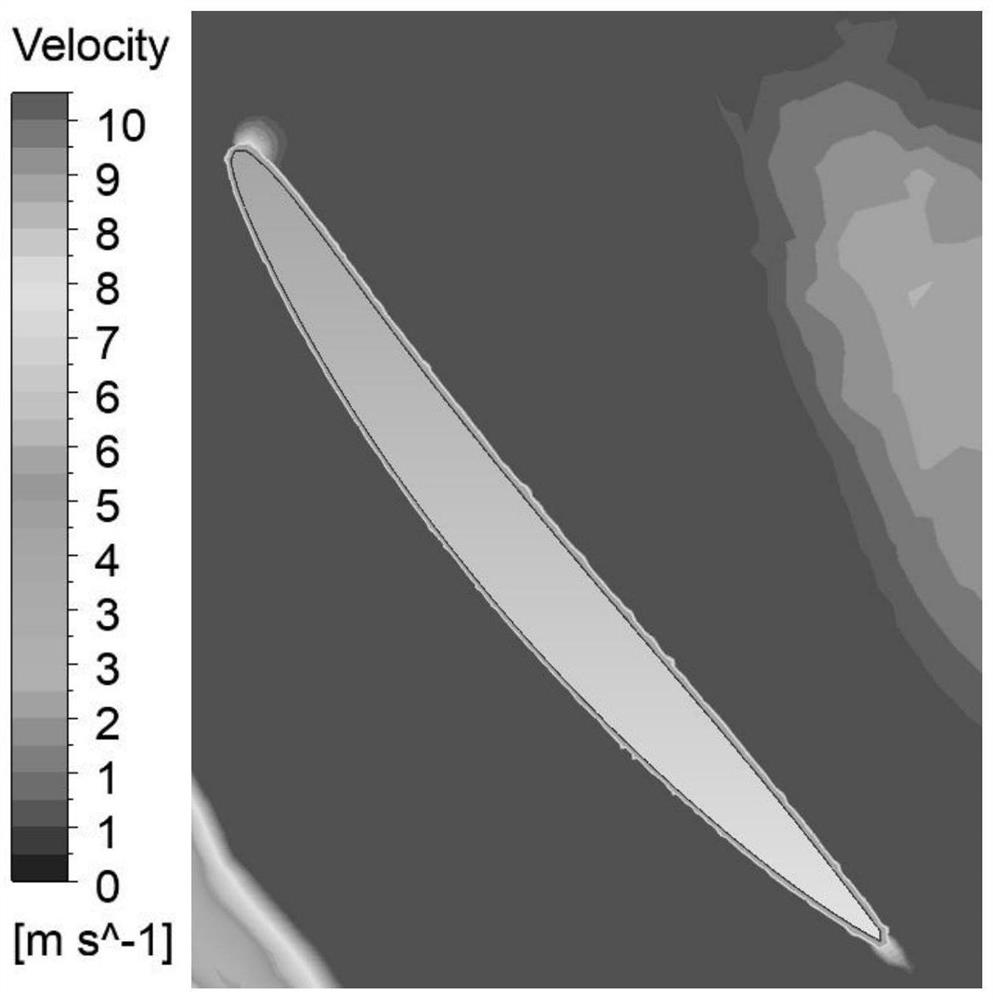

[0044] After the fluid enters the fan from one side of the frame, it first passes through the surface of the fan blade and then flows out from the other side of the fan blade. Before entering the fan blade, turbulent flow and large-scale vortex appear on the back side of the motor frame. At this time, the pits on the surface of the fan blade interact with the large-scale vortex, and the flow of fluid in the pit is blocked, and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com