Multipurpose efficient low-temperature evaporation, concentration and crystallization equipment

A low-temperature evaporation, concentration and crystallization technology, applied in the direction of evaporation separation crystallization, crystallization separation, heat exchange equipment, etc., can solve problems such as material temperature drop, equipment and pipeline ice blockage, equipment damage, etc., to achieve less system failure and maintenance rate Low wear and tear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further clarified below with reference to the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings, and the words "inner" and "outer" "respectively refers to the direction towards or away from the geometric center of a particular part.

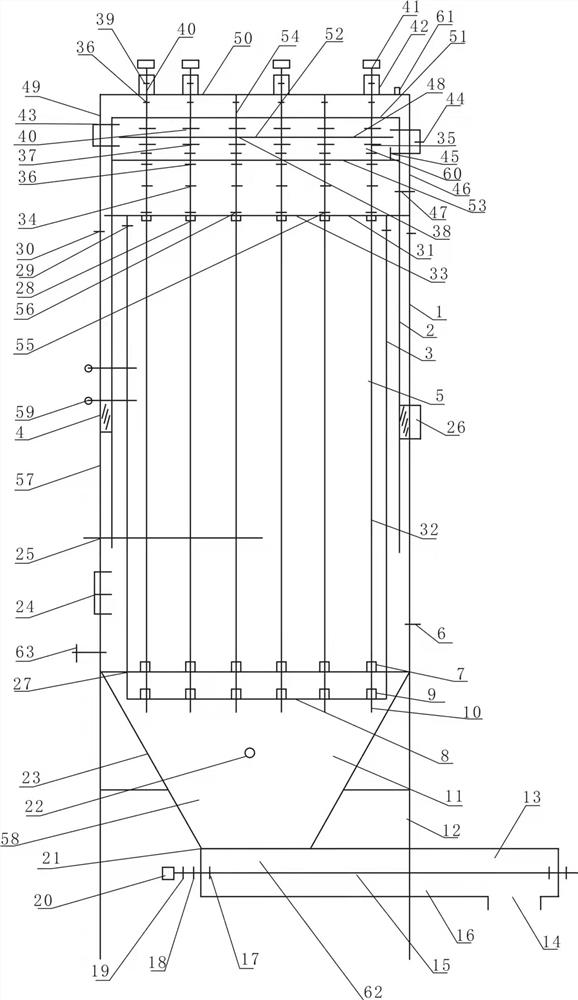

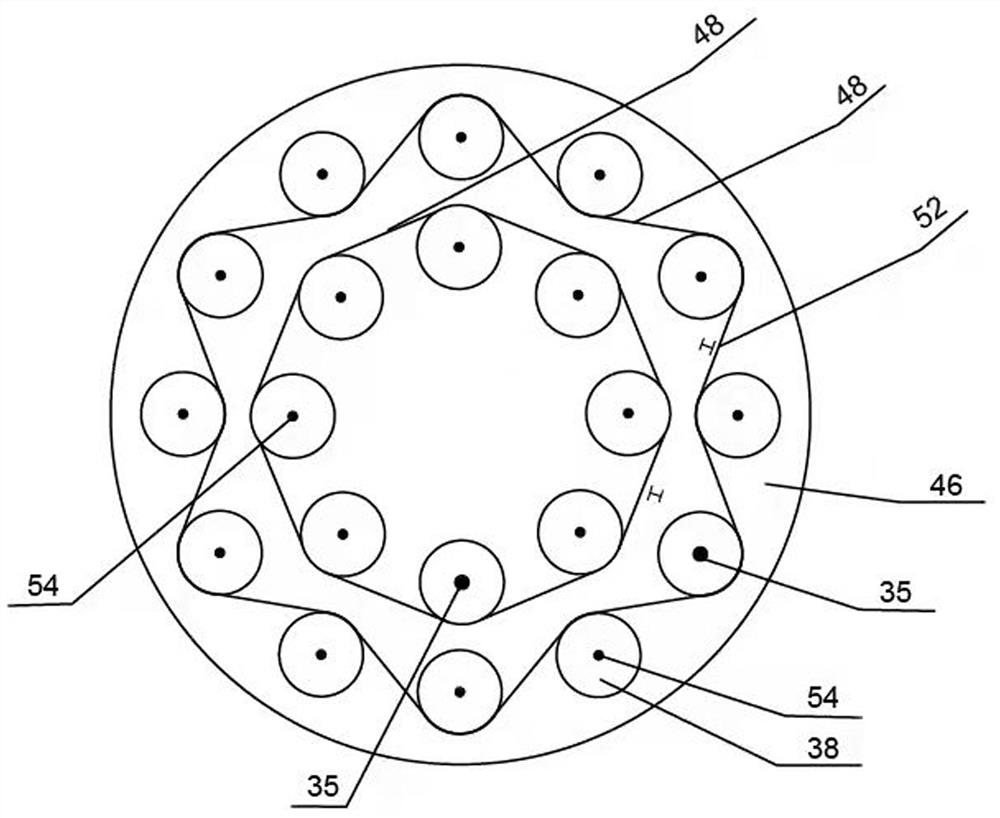

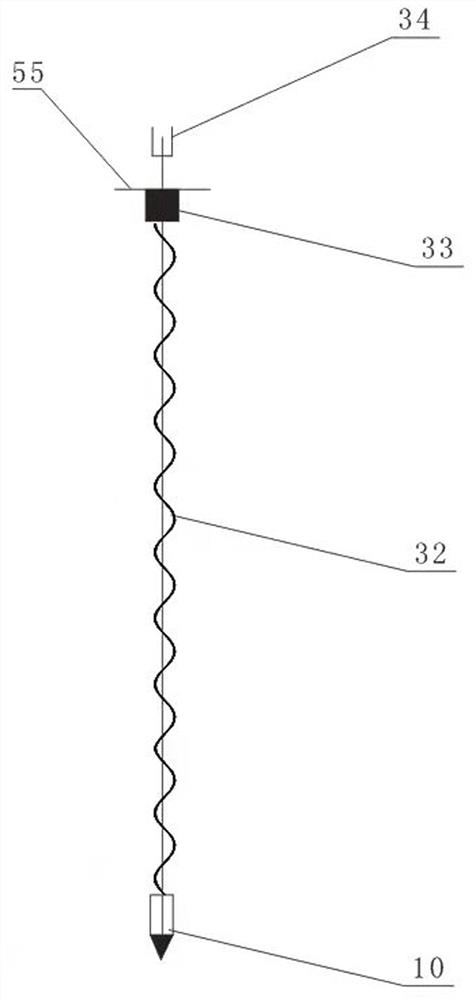

[0039]As shown in the figure, a multi-purpose high-efficiency low-temperature evaporation, concentration and crystallization equipment according to the present invention includes an evaporator barrel 1, a partition 2, a refrigerant evaporation box 3, an oil filter screen 4, a heat exchange tube 5, a liquid level Observation hole 6, anti-wear sleeve under heat exchange tube 7, limiting plate as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com