Cut tobacco drying technology method adopting SH94 to reduce NNK release amount of cigarettes

A process method and release technology, applied in application, tobacco, preparation of tobacco, etc., can solve the problems of reducing NNK release, ignoring the influence of NNK release, and reducing NNK content, so as to reduce NNK release and achieve stable sensory quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

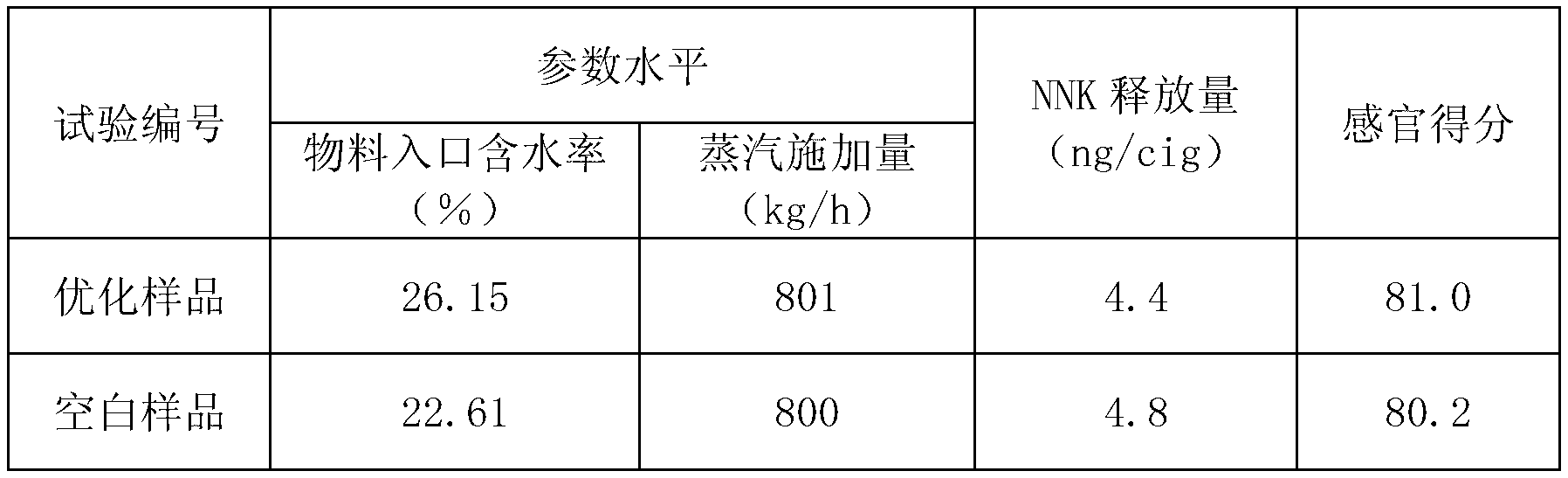

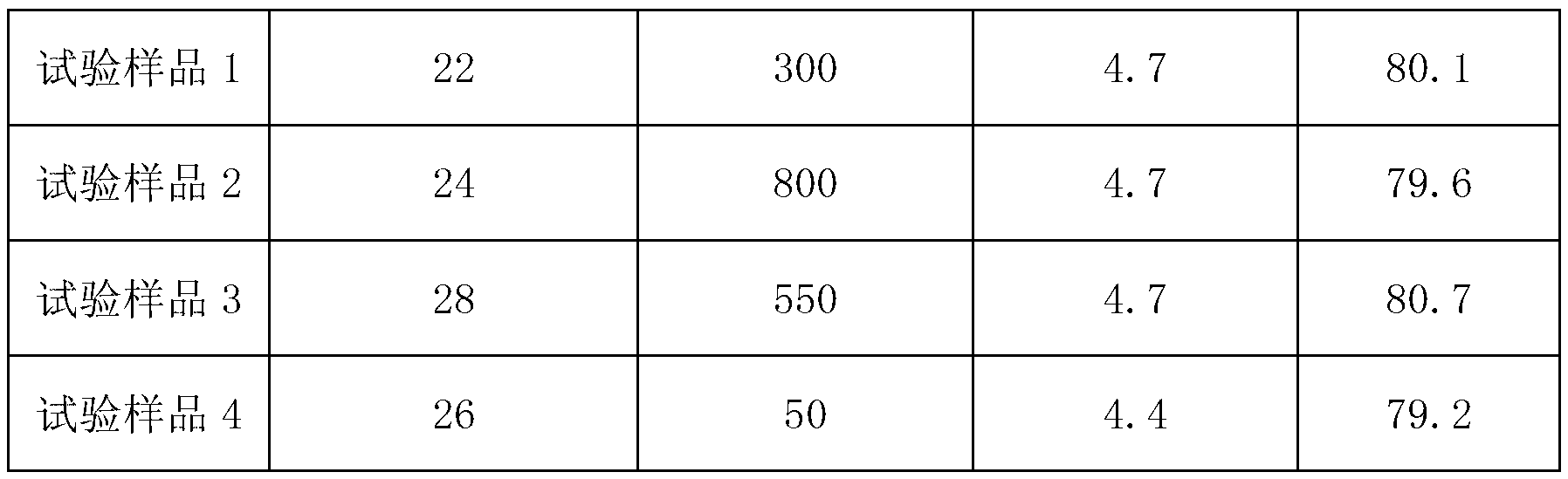

[0022] The model of the high-speed airflow type silk drying machine used in this embodiment is SH94, manufactured by Jiangsu Zhisi Machinery Manufacturing Co., Ltd. Tobacco samples produced according to the equipment parameters of SH94 high-speed airflow drying machine in the silk-making process and drying process formulated by the enterprise were used as blank samples. In the silk making process, the optimized sample was obtained by adjusting the process according to the following parameters: the moisture content of the material inlet was 26.15%, and the amount of steam applied was 801kg / h. The tobacco samples obtained by adjusting the test parameters in the drying process were the test samples. The NNK release and sensory quality of the optimized sample and the blank sample were detected. The results are shown in the table below:

[0023]

[0024] .

[0025] It can be seen from the above table that the NNK release of the optimized sample obtained by optimizing the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com