Preparation method of 96-well enzyme label plate chloramphenicol molecularly imprinted polymer film

A technology of molecular imprinting and chloramphenicol, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problem of no chloramphenicol molecular imprinting polymer film, etc., achieve strong resistance to harsh environments, easy control of reaction conditions, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

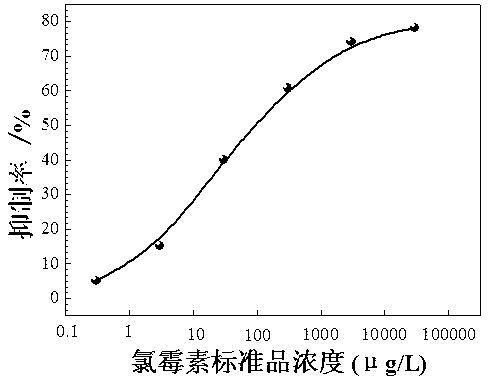

Image

Examples

Embodiment Construction

[0015] a. Weigh 0.25mmol of chloramphenicol in a flask, add 5ml of tetrahydrofuran to it, and sonicate for 5 minutes; Diol dimethacrylate was added into the flask, ultrasonicated for 5min;

[0016] b. Add 5 mg of initiator azobisisobutyronitrile, and sonicate for 15 minutes;

[0017] c. Add the solution obtained in step b to the 96-well ELISA plate dropwise, then put the 96-well ELISA plate into a sealed bag, fill it with nitrogen gas, seal it and irradiate it with a 100W UV lamp (λ=365nm) to initiate polymerization 6 hours;

[0018] d. Then place the 96-well ELISA plate in a methanol-acetic acid mixture with a volume ratio of 3:1, ultrasonically elute for 48 hours, and change the eluent every four hours to remove template molecules;

[0019] e. Dry the 96-well ELISA plate at 50°C for 2 hours to obtain a chloramphenicol molecularly imprinted polymer membrane.

[0020] test:

[0021] 1. Synthetic enzyme-labeled antigen (enzyme-labeled chloramphenicol):

[0022] Use glutar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com