Solar wing hinge line drive characteristic test device

A technology for driving characteristics and testing devices, which is used in measurement devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effect of improving reliability and development level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

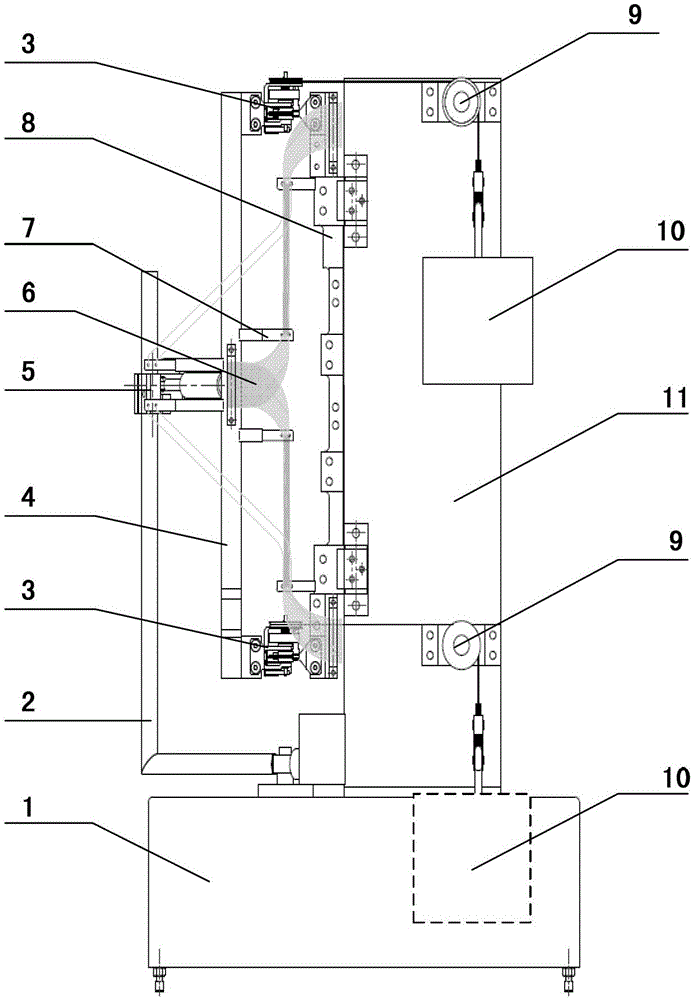

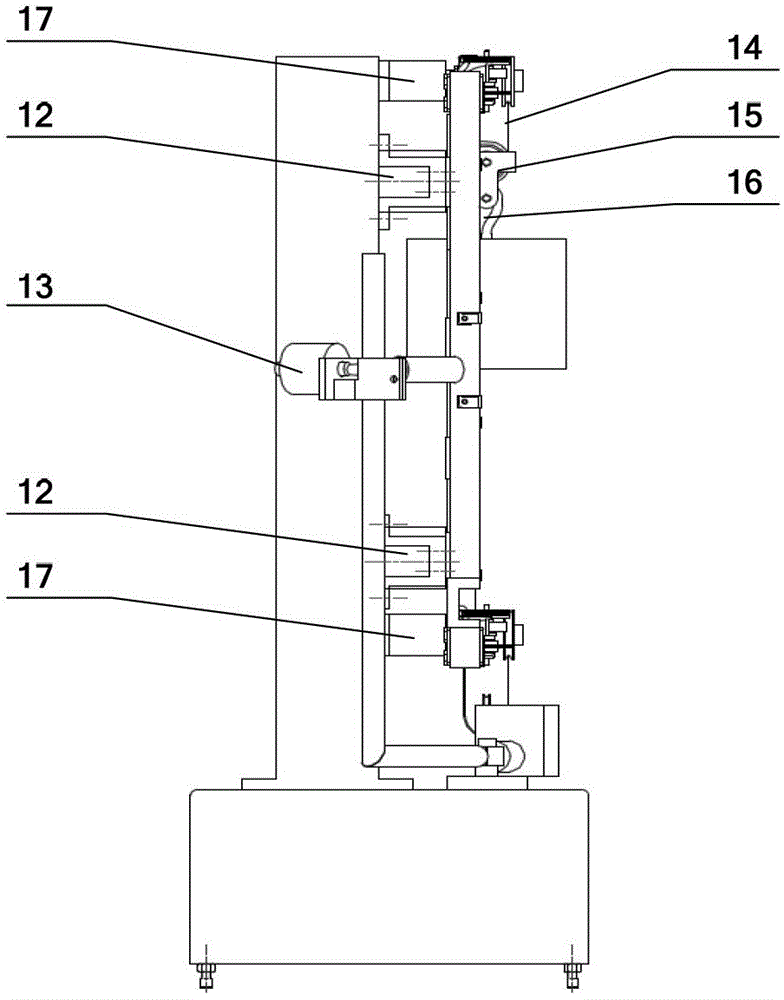

[0020] Simulation test of inter-board hinge cables

[0021] The inter-board test hinge 3 is installed on the fixed bracket 8 and the rotating bracket a4, the inter-board test cable 6 is fixed on the cable fixing seat 7, the main shaft 24 is rotated, and the sensor lever 18 presses the force measuring head of the load cell 13 to generate The pressure signal is sent to the signal processing circuit through the signal line of the load cell 13; the tension of the locking ring is applied, the pulley bracket a17 is installed on the column assembly 11, the double pulley assembly 9 is installed on the pulley bracket a17, and the steel wire rope 14 passes through the hinge roller between the plates The groove is connected with the movable pulley assembly 15, and the upper and lower hinges are installed respectively. When tension is applied, the upper and lower hooks 16 load the same weight 10, such as figure 1 As shown, the main shaft 24 is rotated to realize the simulation test of the...

Embodiment 2

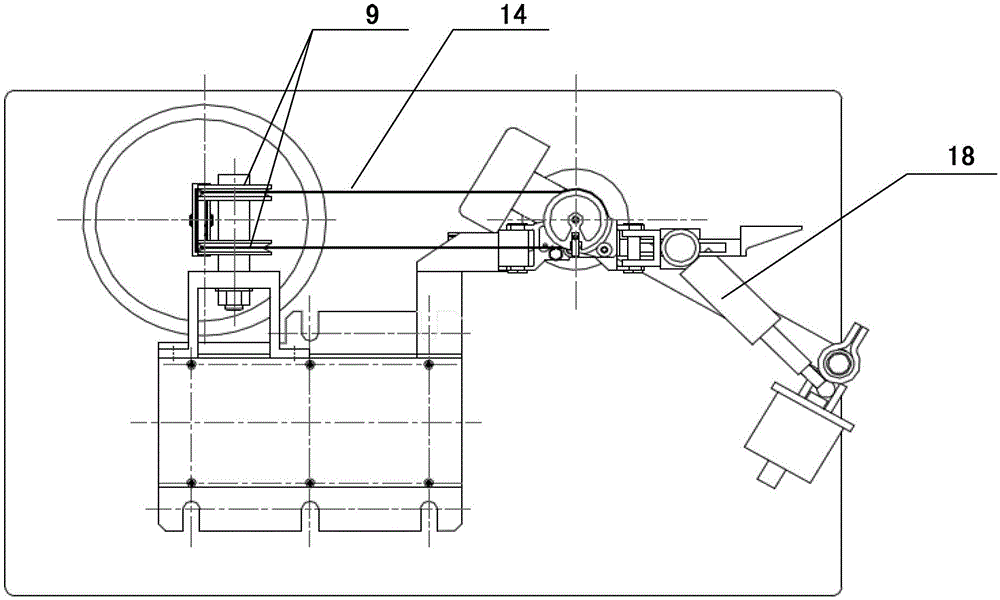

[0023] Root hinge cable simulation

[0024] The root test hinge 22 is installed on the fixed bracket 8 and the rotating bracket b25, the root test cable 23 is fixed on the cable clamp 21, the main shaft 24 is rotated, the sensor lever 18 presses the force measuring head of the load cell 13 to generate a pressure signal, Give the signal processing circuit through the signal line of the load cell 13; apply the locking ring tension, the pulley bracket b20 is installed on the column assembly 11, the double pulley assembly 9 is installed on the pulley bracket b20, the steel wire rope 14 passes through the root hinge roller groove, and The movable pulley assembly 15 is connected, and when the tension is applied, the hook 16 loads the weight 10, such as Figure 4 As shown, the main shaft 24 is rotated to realize the simulation test of the root hinge cable under the tension condition of the locking ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com