A kind of anti-aging asphalt and preparation method thereof

An anti-aging and asphalt technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of not being able to simultaneously improve asphalt’s thermal oxygen resistance and UV aging resistance, and achieve enhanced UV aging resistance and improved thermal oxygen resistance. Aging performance, enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

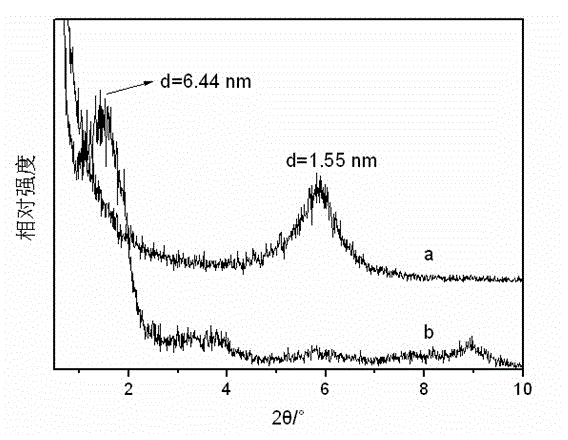

Image

Examples

Embodiment 1

[0025] The anti-aging asphalt of this embodiment is made of the following raw materials in mass percentage: 96.9% of asphalt, 3% of organic vermiculite, and 0.1% of ultraviolet absorber UV531.

[0026] The asphalt is road petroleum asphalt with a softening point of 46.3°C and a penetration of 71 dmm at 25°C.

[0027] The preparation of described organic vermiculite:

[0028] (1) Stir 30 parts by mass of 200-mesh expanded vermiculite, 9 parts of sodium chloride, and 600 parts of deionized water at a constant temperature of 60°C for 5 hours, then centrifuge, filter, and wash repeatedly with deionized water into the eluate Does not contain chloride ions;

[0029] (2) Mix the expanded vermiculite treated in step (1) with 600 parts by mass of deionized water, add 9 parts by mass of dioctadecyldimethylammonium chloride, and stir for 5 hours at a constant temperature of 80°C. Afterwards, centrifuge, filter, and repeatedly wash with deionized water until there is no chloride ion, dr...

Embodiment 2

[0037] The anti-aging asphalt of this embodiment is made of the following raw materials in mass percentage: 96.9% of asphalt, 3% of organic vermiculite, and 0.1% of ultraviolet absorber UV531.

[0038] The asphalt is road petroleum asphalt with a softening point of 46.3°C and a penetration of 71 dmm at 25°C.

[0039] The preparation of described organic vermiculite:

[0040] (1) Stir 30 parts by mass of 200-mesh expanded vermiculite, 9 parts by mass of sodium chloride, and 600 parts by mass of deionized water at a constant temperature of 60°C for 5 hours, then centrifuge, filter, and wash repeatedly with deionized water until washed. The effluent does not contain chloride ions;

[0041] (2) Mix the expanded vermiculite treated in step (1) with 600 parts by mass of deionized water, add 9 parts by mass of dioctadecyldimethylammonium chloride, stir at a constant temperature of 80°C for 5 hours, and then Centrifuge, filter, and repeatedly wash with deionized water until there is...

Embodiment 3

[0048] The anti-aging asphalt of this embodiment is made of the following raw materials in mass percentage: 96.7% of asphalt, 3% of organic vermiculite, and 0.3% of ultraviolet absorber UV531.

[0049] The asphalt is road petroleum asphalt with a softening point of 46.3°C and a penetration of 71 dmm at 25°C.

[0050] The preparation of described organic vermiculite:

[0051] (1) Stir 30 parts by mass of 200-mesh expanded vermiculite, 9 parts by mass of sodium chloride, and 600 parts by mass of deionized water at a constant temperature of 60°C for 5 hours, then centrifuge, filter, and wash repeatedly with deionized water until the The liquid does not contain chloride ions;

[0052] (2) Mix the expanded vermiculite treated in step (1) with 600 parts by mass of deionized water, add 9 parts by mass of dioctadecyldimethylammonium chloride, and stir for 5 hours at a constant temperature of 80°C. Afterwards, centrifuge, filter, and repeatedly wash with deionized water until there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com