Method for preparing myricetin by using vine tea and application of pyrosulfite

A technology of metabisulfite and rattan tea, applied in the direction of organic chemistry and the like, can solve the problems of difficult industrialized production, low yield of myricetin extraction and preparation, and achieve high yield, extensive industrial production, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

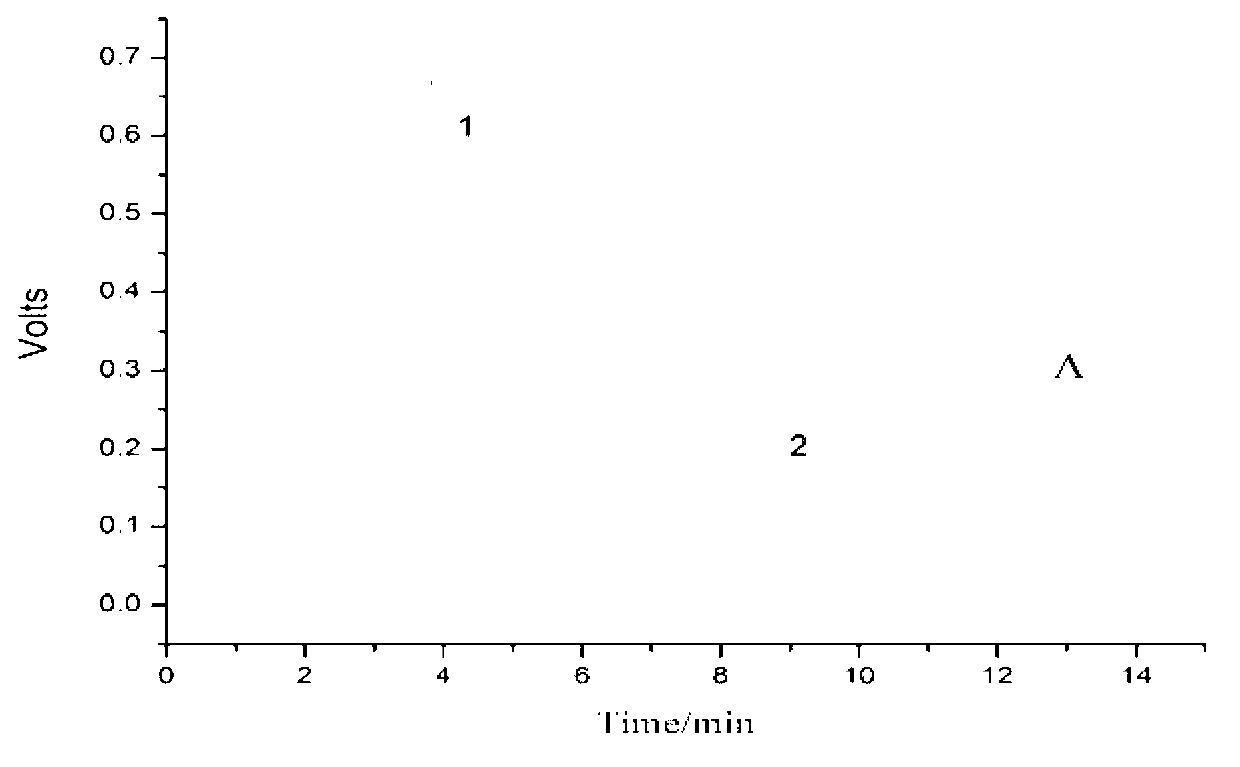

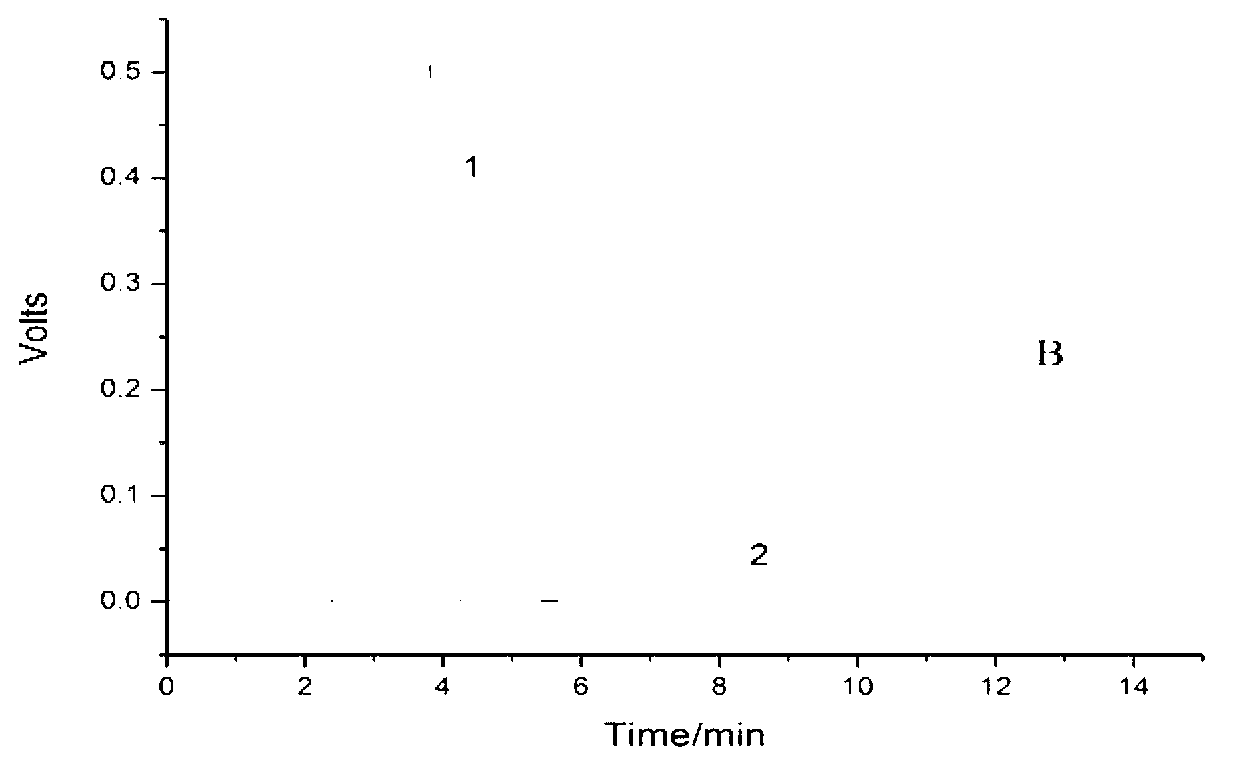

Image

Examples

Embodiment 1

[0031] 1. Extraction of rattan tea

[0032] Weigh 20g of dried rattan tea powder, add about 200mL of water, heat to 95°C to extract for 1 hour, filter while hot, repeat the above operation twice for the filter residue, combine the filtrate three times, concentrate to 200mL, and then stand at 0-5°C for precipitation Pale yellow precipitate, filter with suction, dissolve the filter precipitate with 300mL of absolute ethanol, let it sit for suction filtration, concentrate the filtrate to 100mL under reduced pressure, and obtain the ethanol extract of the extract, which is set aside;

[0033] 2. Dehydrogenation reaction of dihydromyricetin

[0034] Add 100 mL of the concentrated extract above to 250 mL of 20% Na 2 S 2 o 5 In an aqueous solution, react at 100°C for 4 hours; to complete the reaction, pour the mixed solution into an ice-water mixture, let it stand still to precipitate a precipitate, filter with suction, wash the precipitate with ice water several times, and then d...

Embodiment 2

[0037] 1. Extraction of vine tea:

[0038] Weigh 20g of dried vine tea powder, add 200mL of water, heat to 95°C for extraction for 1 hour, filter while hot, repeat the above operation twice for the filter residue, combine the filtrate three times, concentrate to 200mL; Suction filter the yellow precipitate, dissolve the filtered precipitate with 300mL of absolute ethanol, let it stand for suction filtration, and concentrate the filtrate to 100mL under reduced pressure to obtain the ethanol extract of the extract, which is set aside.

[0039] 2. Dehydrogenation reaction of dihydromyricetin:

[0040] Add 100 mL of the concentrated extract above to 250 mL of 20% K 2 S 2 o5 In an aqueous solution, react at 100°C for 4 hours; to end the reaction, pour the mixed solution into an ice-water mixture, let it stand still to precipitate a precipitate, filter with suction, wash the precipitate with ice water several times, and then dry it in a vacuum at 40°C to obtain a yellow-green soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com