Process for producing industrial phosphate with calcination method

An industrial phosphoric acid and phosphate technology, applied in the fields of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve low energy and material consumption and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

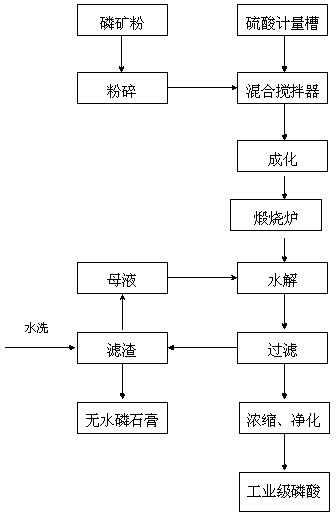

Method used

Image

Examples

Embodiment 1

[0026] Using 1260 tons of Phosphate Mine in Laomergshan, Jinkouhe District, Leshan City, Sichuan Province 2 o 5 21.5% of the phosphate rock is used to produce industrial phosphoric acid. First, the phosphate rock is crushed and then crushed again. The crushed phosphate rock powder is passed through a 120-mesh sieve, and the P contained in it is 2 o 5 The mass percentage content of CaO is about 21%, the mass percentage content of CaO is about 48%, Fe 2 o 3 The mass percentage content of Al is about 1.2%, Al 2 o 3 The mass percentage of is about 0.8%, the mass percentage of MgO is about 6%, the mass percentage of SiO2 is about 2.4%, and the mass percentage of F is about 2.1%;

[0027] (2) Mixing and forming: Put phosphate rock powder and sulfuric acid with a concentration of 98% into the mixing mixer in proportion to stir, and the mixed materials are transported to the forming field for 3 hours, the mass ratio of phosphate rock powder to sulfuric acid =1:0.5, the two are e...

Embodiment 2

[0036] Using 120 tons containing P 2 o 5 21.5% of the phosphate rock is used to produce industrial phosphoric acid. Firstly, the phosphate rock is crushed and crushed again. The crushed phosphate rock powder is passed through a 120-mesh sieve. The selected phosphate rock is low-grade phosphate rock, which contains P 2 o 5 The mass percentage content of CaO is about 21%, the mass percentage content of CaO is about 48%, Fe 2 o 3 The mass percentage content of Al is about 1.2%, Al 2 o 3 The mass percentage of is about 0.8%, the mass percentage of MgO is about 6%, the mass percentage of SiO2 is about 2.4%, and the mass percentage of F is about 2.1%;

[0037] (2) Mixing and forming: Put the phosphate rock powder and sulfuric acid into the mixing mixer in proportion to stir. After mixing, the materials are transported to the forming field for 3 hours. Accurate measurement by flow meter, accurate measurement of phosphate rock powder by belt scale, mass ratio of phosphate rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com