Assembler for lock cylinder and lock cylinder surface cover of automobile

A technology of assembler and car lock, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, achieve the effect of improving production efficiency and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

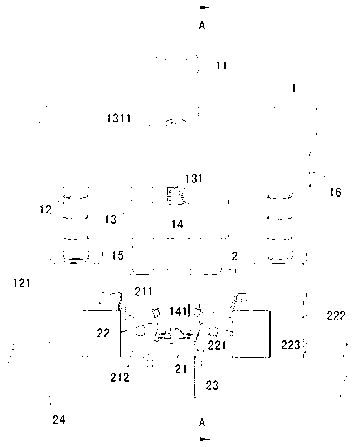

[0023] see image 3 . The assembler of this embodiment includes an upper template 1 and a lower template 24. The upper template 1 includes a separate pressing plate 16, but after being fixed, the two form an integral part, which is mainly for the convenience of tooling. A connecting end 11 is provided on the top of the upper template 1, and the components of the upper template 1 can be fixedly connected to the punching machine by using it. As components of the upper formwork 1 , there are: two guide pillars 12 on both sides, two pressure pillars 15 in the middle, and a transmission rod 14 on the rear side of the upper formwork 1 . The column shafts of the left and right pressure columns 15 pass through the left and right through holes of the guide block 13 respectively, and the guide block 13 is hung on the upper template 1 after being positioned by the screw rod 131 .

[0024] As a component of the lower formwork 24, there is a slide block 21 located in the middle, the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com