Hotpot condiment and preparation process thereof

A hot pot bottom material and preparation technology, which is applied in the food field, can solve the problems of hot pot with bitter taste, increase the cost of hot pot, poor taste, etc., and achieve the effect of uniform bottom material, high degree of automation, and no difference in taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

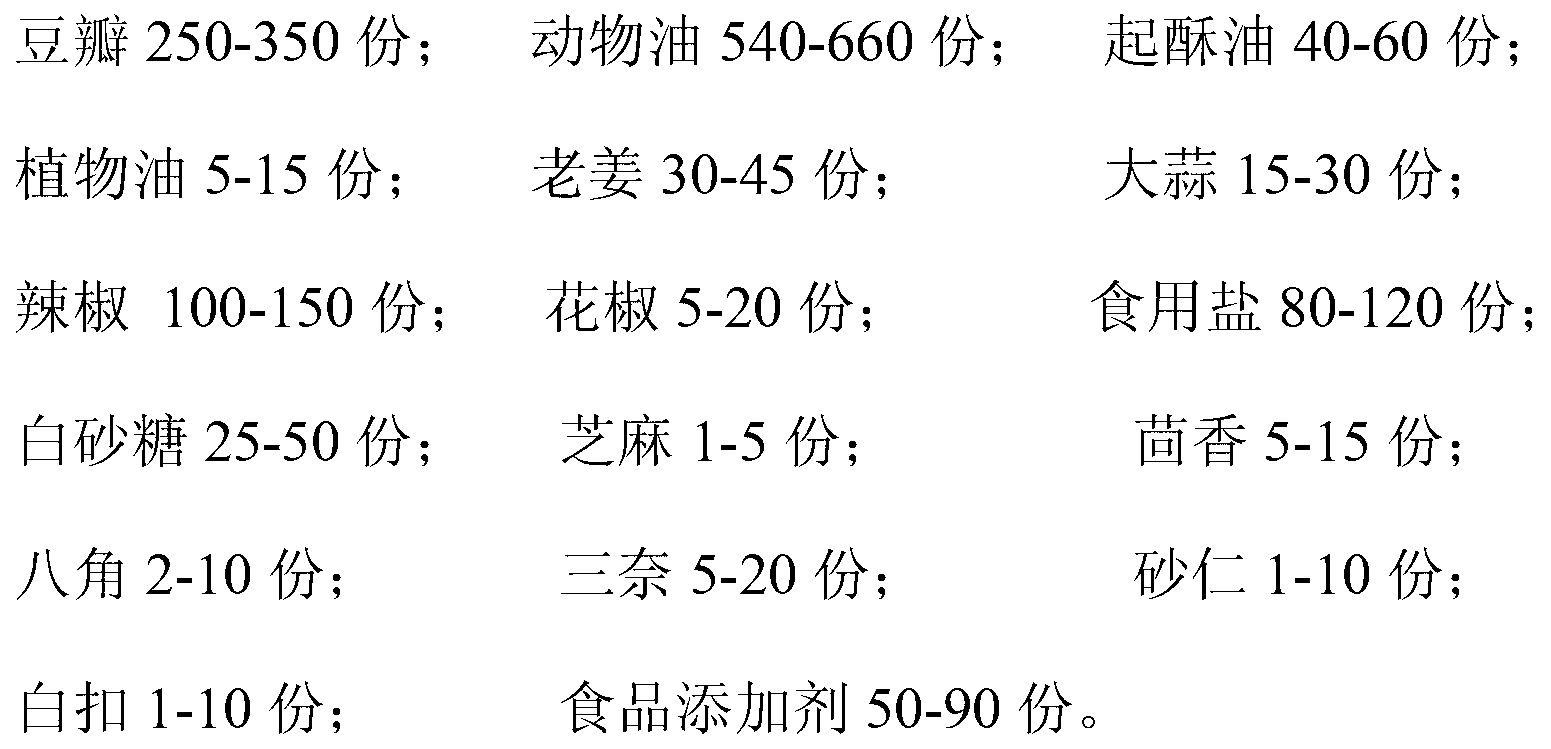

[0021] 1. Prepare materials: Measure 660 parts of butter, 5 parts of rapeseed oil, 40 parts of shortening, 350 parts of watercress, 45 parts of ginger, 15 parts of garlic, 150 parts of pepper, 5 parts of Chinese pepper, 80 parts of edible salt, white sugar 25 parts, 5 parts of sesame, 15 parts of fennel, 2 parts of star anise, 20 parts of three Nye, 1 part of amomum and 1 part of white buckle.

[0022] Prepare 50 parts of food additives: prepare by mixing monosodium glutamate and disodium nucleotide nucleotides at a weight ratio of 2:1 and set aside.

[0023] 2. Prepare the bottom material: first add vegetable oil, shortening and animal oil to the oil pool, turn the solid oil into liquid, transfer the oil into the frying pan through the pump, boil it on high heat until it boils, then add garlic, ginger and watercress, Cook for 25 minutes while stirring with a mixer, then add chili, pepper, edible salt, white sugar, sesame, fennel, star anise, three Nye, amomum, white buckle an...

Embodiment 2

[0025] 1. Prepare materials: Measure 540 parts of butter, 15 parts of rapeseed oil, 60 parts of shortening, 250 parts of watercress, 30 parts of ginger, 30 parts of garlic, 100 parts of pepper, 20 parts of peppercorns, 120 parts of edible salt, white sugar 50 parts, 1 part of sesame, 5 parts of fennel, 10 parts of star anise, 5 parts of three Nye, 10 parts of amomum and 10 parts of white buckle.

[0026] Prepare 90 parts of food additives: prepare by mixing monosodium glutamate and disodium nucleotide nucleotides at a weight ratio of 2:1 and set aside.

[0027] 2. Prepare the bottom material: first add vegetable oil, shortening and animal oil to the oil pool, turn the solid oil into liquid, transfer the oil into the frying pan through the pump, boil it on high heat until it boils, then add garlic, ginger and watercress, Cook for 35 minutes while stirring with a mixer, then add chili, pepper, edible salt, white sugar, sesame, fennel, star anise, three Nye, amomum, white buckle ...

Embodiment 3

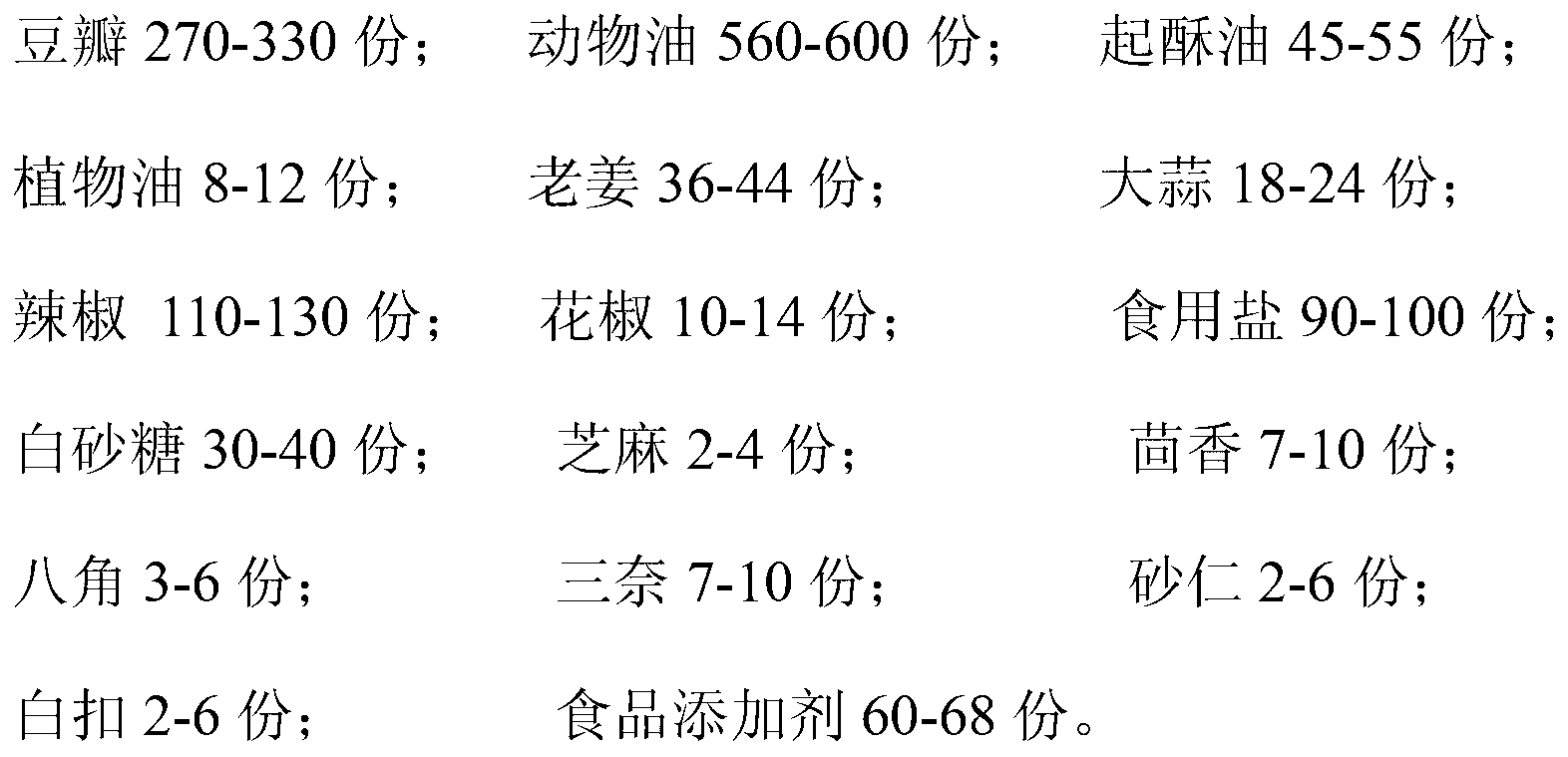

[0029] 1. Preparation: Measure 600 parts of butter, 10 parts of rapeseed oil, 50 parts of shortening, 300 parts of watercress, 40 parts of ginger, 20 parts of garlic, 120 parts of pepper, 12 parts of pepper, 100 parts of edible salt, and white sugar 35 parts, 2 parts of sesame, 9 parts of fennel, 3 parts of star anise, 7 parts of three Nye, 2 parts of amomum and 2 parts of white buckle.

[0030] Prepare 64 parts of food additives: prepare by mixing monosodium glutamate and disodium nucleotide nucleotides at a weight ratio of 2:1 and set aside.

[0031] 2 Prepare the bottom material: first add vegetable oil, shortening and animal oil to the oil pool, turn the solid oil into liquid, transfer the oil into the frying pan through the pump, boil it on high heat until it boils, then add garlic, ginger and watercress, through Cook for 28 minutes while stirring with the mixer, then add chili, Chinese prickly ash, edible salt, white sugar, sesame, fennel, star anise, three Nye, amomum, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com