Magnetic levitation planetary transmission speed control machine

A technology of planetary transmission and speed changer, which is applied in electromechanical transmission devices, electromechanical devices, electric components, etc., can solve the problems of small torque and low resource utilization, and achieve the effects of large transmission torque, long machine life and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

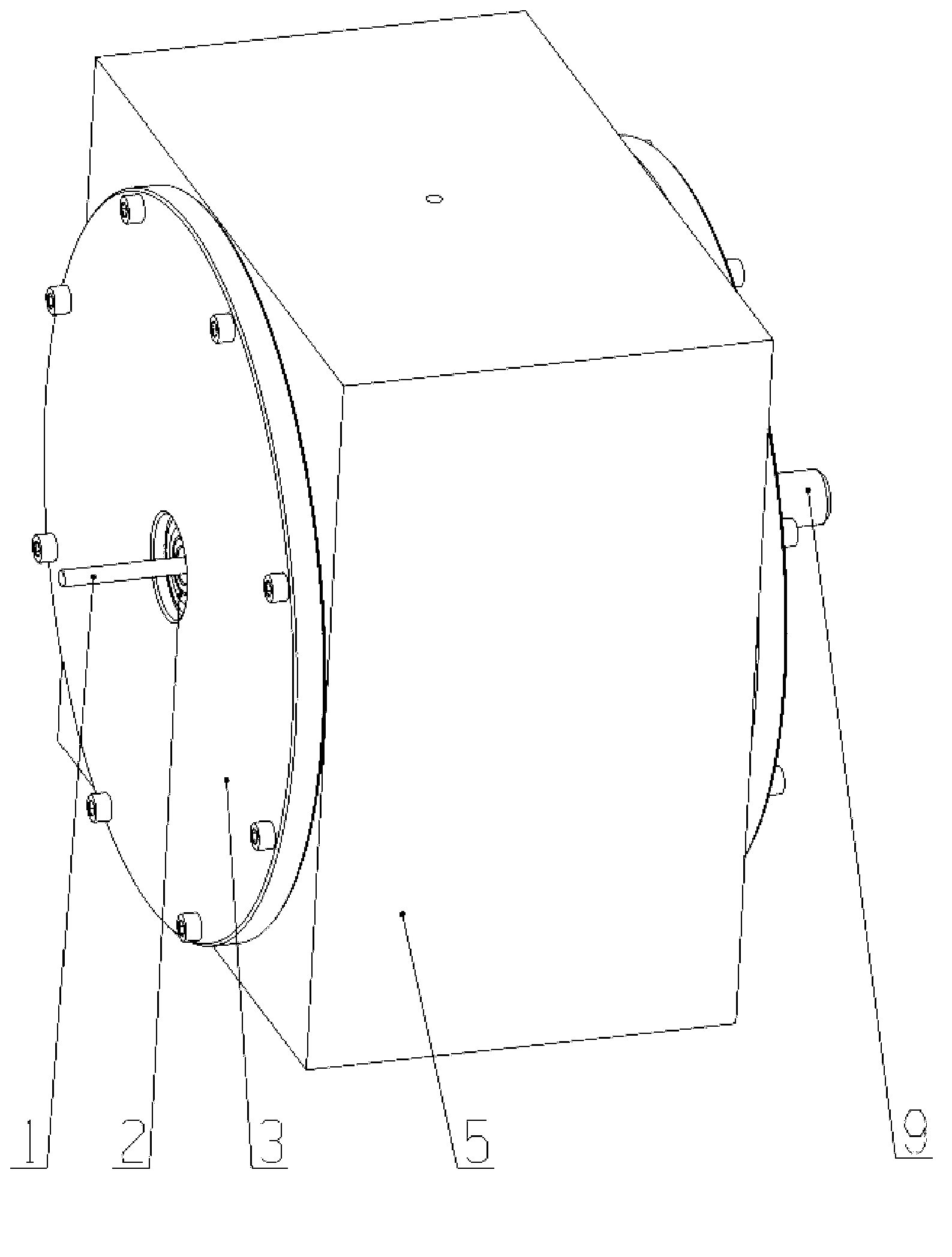

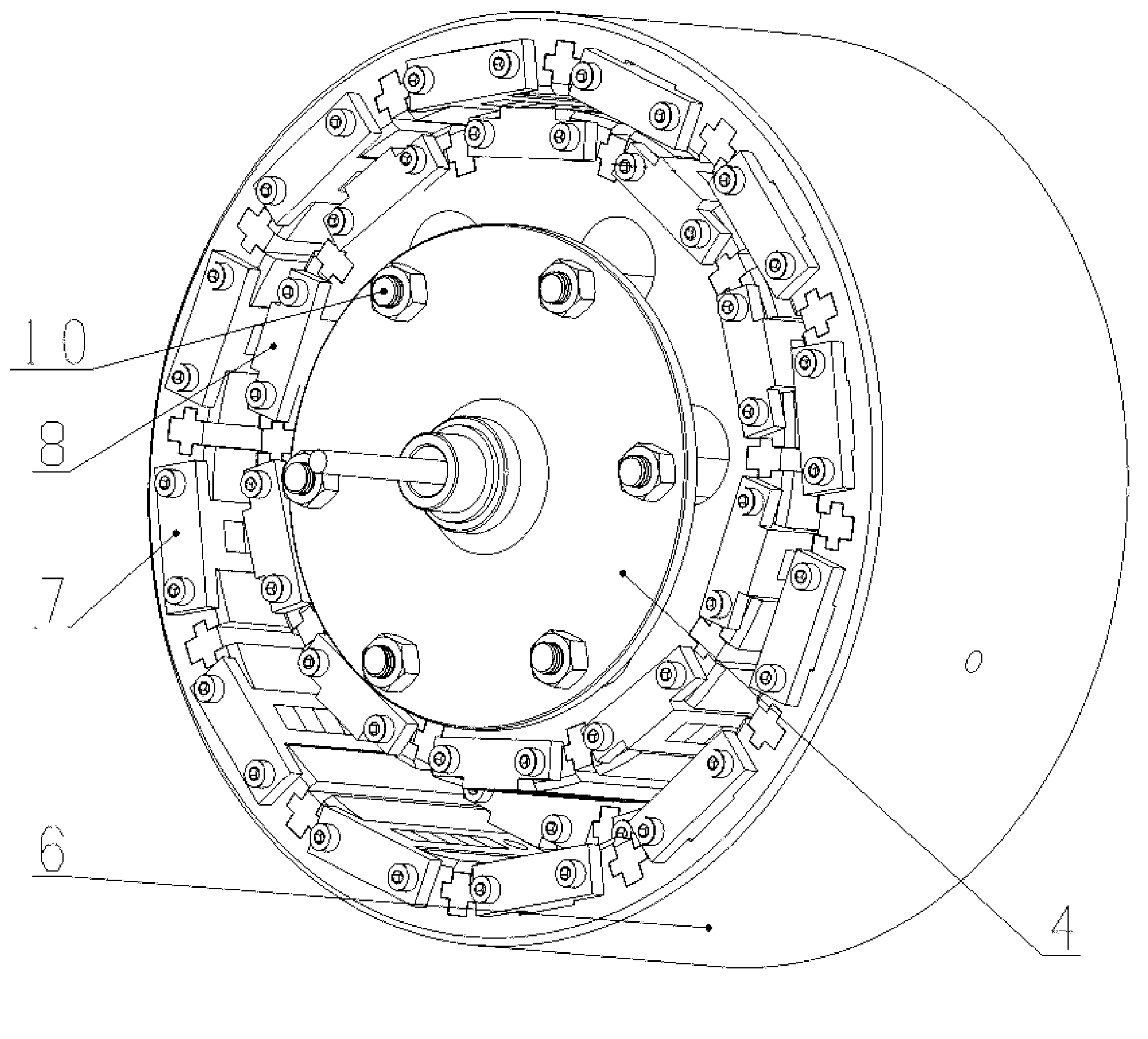

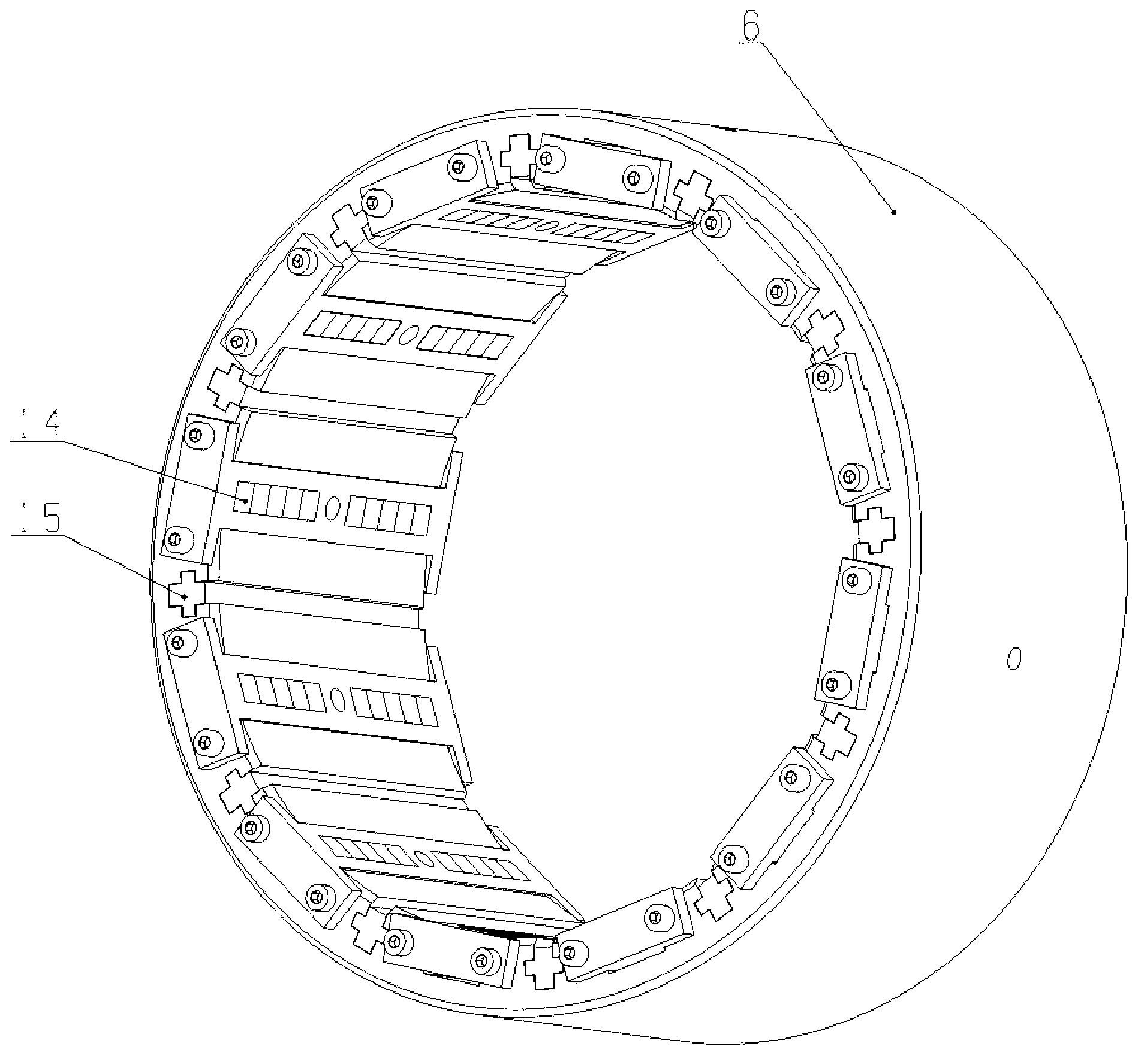

[0032] As shown in the figure, a magnetic levitation planetary transmission speed changer includes an I shaft 1, a housing 5, an II shaft 9, and a permanent magnet 14. The inner side of the housing 5 is provided with an inner ring gear 6, and the inner ring gear 6 is provided with straight grooves, the number is 12, and permanent magnet mounting frame I7 is arranged in the straight grooves, and end caps 3 are provided at both ends of the housing 5, and the center of the end caps 3 at one end of the housing 5 is connected to the input through the bearing 2 The connecting shaft 4, the center of the end cover 3 at the other end is connected to the II shaft 9 through the bearing 2, one end of the I shaft 1 is installed at the center of the input connecting shaft 4, and the other end is installed at the center of the II shaft 9, and the I shaft 1 is equipped with an eccentric shaft 11 through a key, and the eccentric shaft 11 is connected to the planetary wheel 13 through a bearing....

Embodiment 2

[0035] The difference from Embodiment 1 is that the permanent magnets 14 on the permanent magnet mounting frame I7 and the permanent magnet mounting frame II8 are arranged in a Halbach manner, and the magnetism is mutual repulsion.

[0036] This embodiment can accomplish greater torque transmission than Implementation 2.

Embodiment 3

[0038] The difference from Embodiment 1 or 2 is that the pitch of the straight grooves of the ring gear 6 is equidistant, and the number is three, and the pitch of the straight grooves on the planetary gear 13 is equidistant, and the number is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com