Microfluidic chip for sorting and application thereof

A microfluidic chip and chip technology, applied in the direction of using electricity/wave energy to treat microorganisms, specific-purpose bioreactors/fermenters, microorganisms, etc., can solve the problem of complex chip manufacturing process, repeatability to be verified, chip width Limited and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Example 1 Microfluidic chip

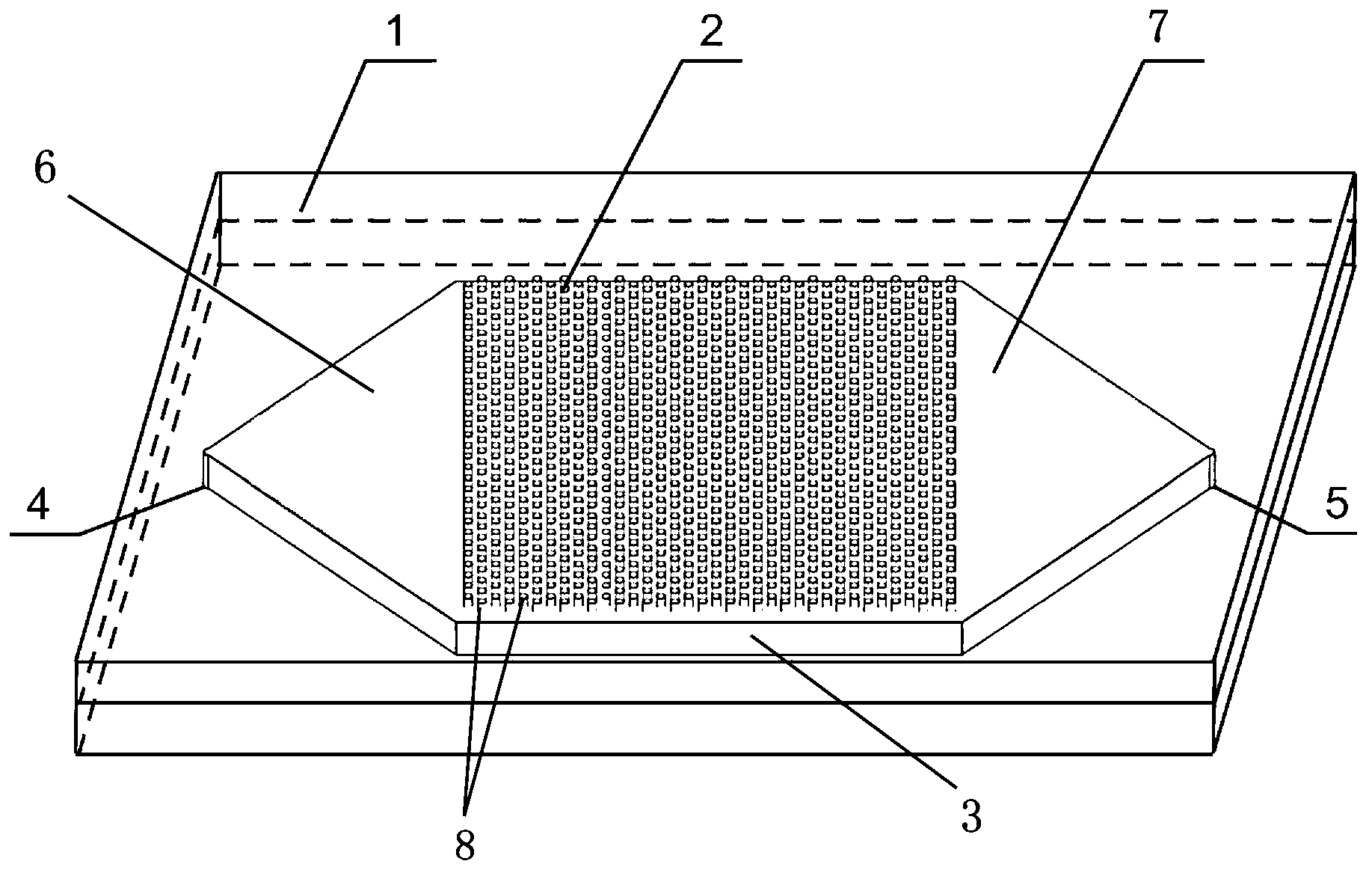

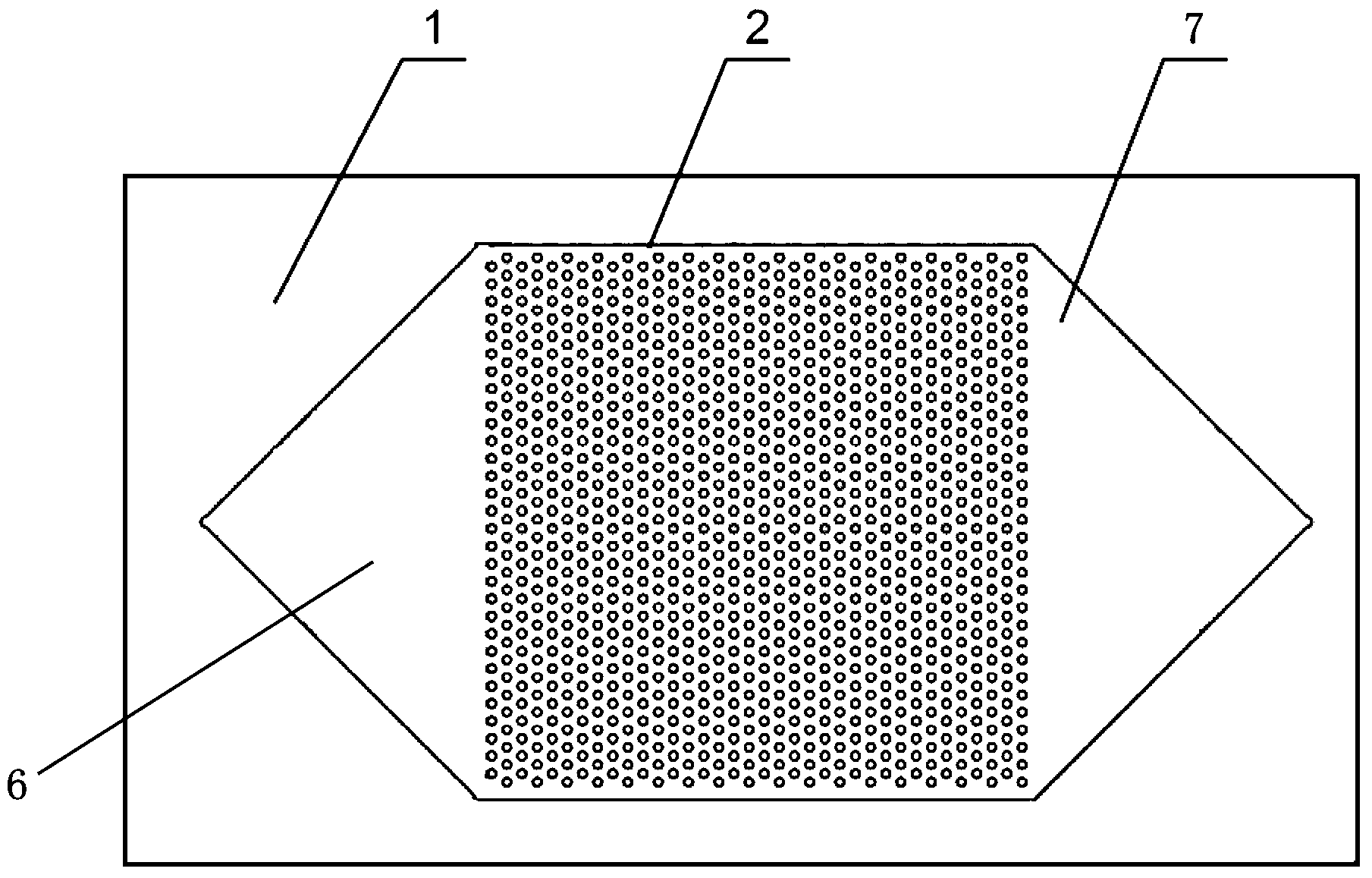

[0137] Such as Figure 1-4 As shown, the chip of the present invention is integrally formed, including:

[0138] (1) Chip inlet 4: located on the bottom surface of the microfluidic chip 1, the shape is a circle with a diameter of 500 microns, and the chip inlet 4 is connected to the main channel 3 of the chip.

[0139] (2) Main channel 3 of the chip: the main channel 3 consists of an inlet channel 6 of an isosceles right triangle with a hypotenuse length of 25.4 mm, a square capture area channel 2 with a side length of 25.4 mm, and an isosceles right angle with a hypotenuse length of 25.4 mm. A triangular exit channel 7 is formed, and the hypotenuses of the two isosceles right triangles coincide with the left and right sides of the square respectively. The chip outlet 5 and the chip inlet 4 are respectively located at the right angles of the inlet channel 6 and the outlet channel 7 of the isosceles right triangle, and the right angle of t...

Embodiment 2

[0142] Example 2 Microfluidic chip

[0143] Such as figure 1 and Figure 4 As shown, the structure of the chip in this embodiment is basically the same as that in Embodiment 1, including chip inlet, chip main channel and chip outlet. The difference is that the chip is a split structure, including a first substrate located above and a second substrate located below, and the two are closed to each other. The first substrate is provided with a collection chamber area for collecting cells or other substances to be sorted, and the collection chamber area is provided with a plurality of collection chambers with openings facing downwards, and the second substrate is provided with a chip inlet, a chip outlet, and a main channel. lower surface9. When the first substrate and the second substrate were closed, the side of the first substrate provided with the collection cell area and the main channel lower surface of the second substrate jointly formed a chip main channel for the flow ...

Embodiment 3

[0144] Example 3 Sorting of circulating tumor cells in peripheral blood of patients with colon cancer using the chip of the present invention

[0145] (1) Take 5ml of peripheral venous blood from patients with colon cancer, and remove the first 2ml of peripheral blood to avoid skin epithelial cell contamination. The remaining blood samples are collected in EDTA anticoagulant tubes, stored and transported at 4 degrees Celsius, and tested within 4 hours.

[0146] (2) Flush the channel of the microfluidic chip with block polyether F-108 for 30 minutes to prevent non-specific cell adhesion, and then place a permanent magnet with a magnetic field strength of 500mT above the capture area of the microfluidic chip.

[0147] (3) According to 10 7 For the ratio of magnetic beads / ml blood, add 150 microliters of immunomagnetic beads conjugated with anti-human epithelial cell adhesion molecule antibody (purchased from Invitrogen) to 3 ml of blood in step (1), and incubate at 4°C 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com