Cold-resistant anti-corrosion glass fiber reinforced polycarbonate composite material as well as preparation method and applications thereof

A glass fiber and polycarbonate technology, which is used in the field of cold-resistant and corrosion-resistant glass fiber reinforced polycarbonate composite materials and its preparation, can solve the problems of notch-sensitive wear resistance, poor processing fluidity, and easy stress cracking, and achieves high mechanical Strength and impact resistance, strong low temperature resistance, the effect of improving production/living conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

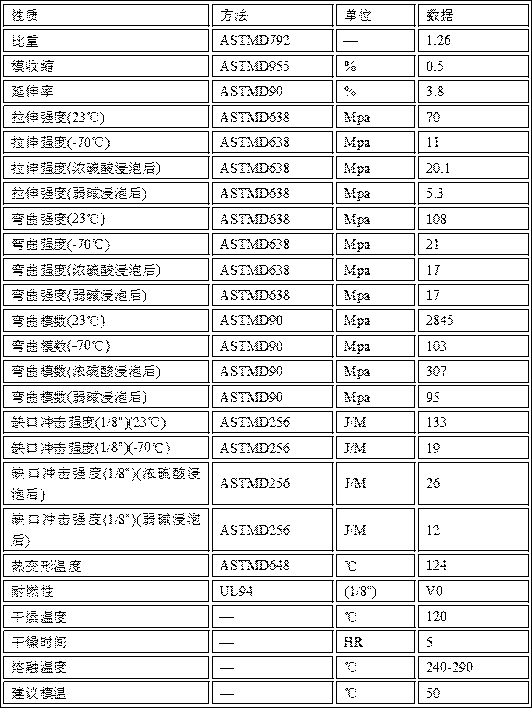

Embodiment 1

[0076] A cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material of this embodiment, its raw material formula is composed of the following components by weight:

[0077] 81 parts of polycarbonate;

[0078] 20 parts of glass fiber;

[0079] Antioxidant K21 0.5 parts;

[0080] Lubricant PETS 0.5 part;

[0081] Anti-ultraviolet absorber UV-234 0.5 parts;

[0082] 5 copies of EMA;

[0083] METABLEN SX-006 8 copies;

[0084] ESL-P200 6 copies

[0085] PET 10 parts.

[0086] Among the above raw material formulations, polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-006, ESL-P200, and PET are all commercially available products.

[0087] The preparation method of the above-mentioned cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material comprises the following steps:

[0088] Mix polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-0...

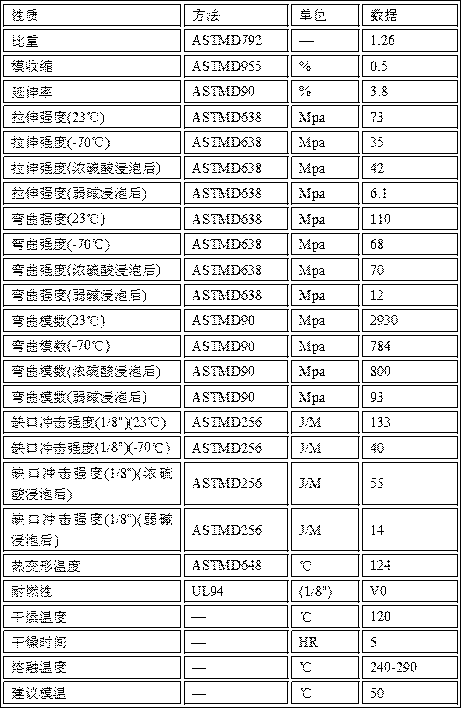

Embodiment 2

[0097] A cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material of this embodiment, its raw material formula is composed of the following components by weight:

[0098] 55 parts of polycarbonate;

[0099] 8 parts glass fiber;

[0100] Antioxidant K21 0.2 parts;

[0101] Lubricant PETS 0.1 parts;

[0102] Anti-ultraviolet absorber UV-234 0.1 part;

[0103] 2 copies of EMA;

[0104] METABLEN SX-006 2 parts;

[0105] 5 copies of PET;

[0106] ESL-P200 3 copies.

[0107] Among the above raw material formulations, polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-006, ESL-P200, and PET are all commercially available products.

[0108] The preparation method of the above-mentioned cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material comprises the following steps:

[0109] Mix polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-00...

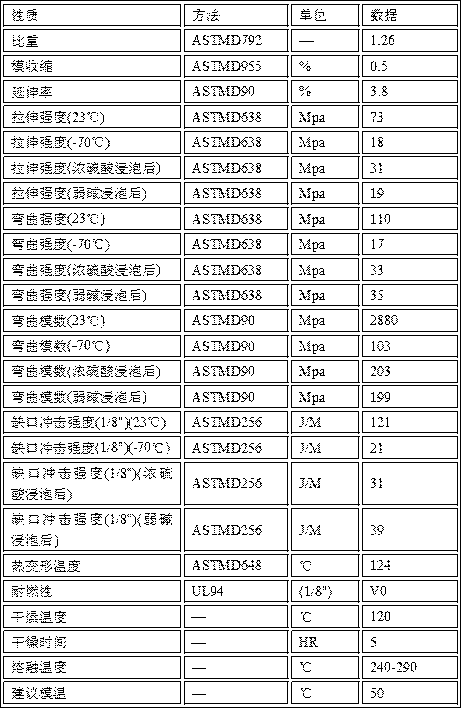

Embodiment 3

[0118] A cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material of this embodiment, its raw material formula is composed of the following components by weight:

[0119] 70 parts of polycarbonate;

[0120] 15 parts of glass fiber;

[0121] Antioxidant K21 0.8 parts;

[0122] 0.3 copies of PETS;

[0123] Anti-ultraviolet absorber UV-234 0.3 parts;

[0124] 3 copies of EMA;

[0125] METABLEN SX-006 5 copies;

[0126] ESL-P200 3 copies;

[0127] PET 8 servings.

[0128] Among the above raw material formulas, polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-006, ESL-P200, and PET are all commercially available products.

[0129] The preparation method of the above-mentioned cold-resistant and anti-corrosion glass fiber reinforced polycarbonate composite material comprises the following steps:

[0130] Mix polycarbonate, glass fiber, antioxidant, PETS, UV-234, toughening agent EMA, METABLEN SX-006, ES...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com