Controllable fully-degradable macromolecular material-based composite material and preparation method thereof

A technology of polymer materials and composite materials, which is applied in the field of controllable and fully degradable polymer material-based composite materials and their preparation, and achieves the effect of high biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First prepare 25g / L PLLA solution with chloroform as solvent, then add 5g / L magnesium hydroxide powder, stir mechanically for 1h to obtain a suspension with magnesium hydroxide as solid dispersed phase and PLLA organic solvent-based solution as liquid. The suspension was cast on a clean glass sheet, and dried in a vacuum drying oven at a controlled temperature of 60° C. for 48 hours, and a film-like composite material was obtained after the solvent was completely evaporated. After crushing the above-mentioned film-like composite material, it was hot-pressed (hot-pressing temperature 175°C, pressure 17MPa) to obtain a hydrogen oxide film with a size of 20mm×10mm×2.5mm and an amount of magnesium hydroxide added to the mass fraction of the composite material of 16.67%. Magnesium / PLLA bulk composite specimen.

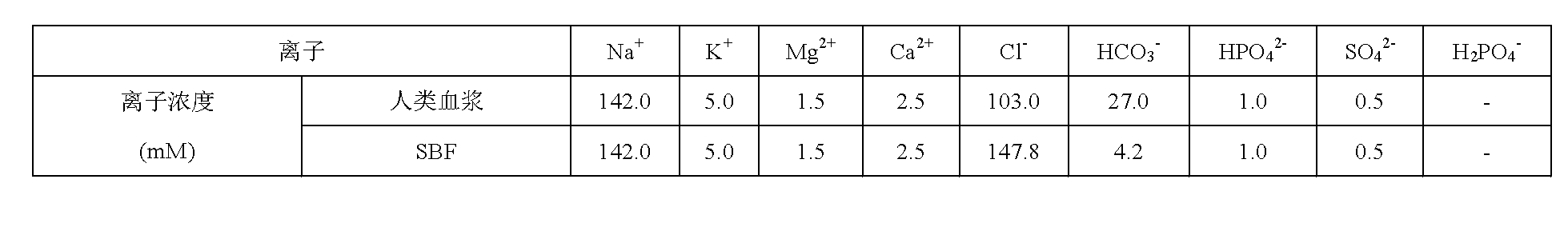

[0024] Take SBF (simulated body fluid) as the test medium (see Table 1 for the comparison between its composition and the chemical composition of human plasma), and ...

Embodiment 2

[0026] Except that PLLA is changed to PLGA, magnesium hydroxide is changed to magnesium oxide, and organic solvent is changed to dichloromethane, the other conditions for composite material preparation are the same as in Example 1. As a result, the amount of magnesium oxide added accounts for 16.67% of the composite material mass fraction. MgO / PLGA bulk composites. The in vitro biodegradability test was carried out on the sample as in Example 1. The results of mass change monitoring show that the time required for the complete degradation of the composite material sample and the pure PLGA control sample is 140d and 94d respectively; The pH change of the test medium due to degradation was 1.23 higher than that of the pure PLGA control sample, which confirmed that the acidification effect produced by the degradation process of the polymer material was significantly weakened by the addition of magnesium oxide.

Embodiment 3

[0028] Except changing the 5g / L magnesium hydroxide into a mixture of 5g / L magnesium oxide and 5g / L magnesium hydroxide, and changing the organic solvent into epichlorohydrin, the other conditions for the preparation of the composite material are controlled the same as in Example 1, and the result is an oxidized The mass fraction of magnesium and magnesium hydroxide accounted for 14.29% of the bulk composite material. The in vitro biodegradability test was carried out on the sample as in Example 1. The results of mass change monitoring show that the time required for the complete degradation of the composite sample and the pure PLLA control sample is 178d and 82d respectively; The pH change of the test medium due to degradation was 1.97 higher than that of the pure PLLA control sample, which confirmed that the acidification effect produced by the degradation process of polymer materials was significantly weakened by the addition of magnesium oxide and magnesium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com