Preparation method of microcapsules for rubber material self-repair

A rubber material and microcapsule technology, applied in the field of self-healing microcapsules, can solve the problems of high modulus of epoxy resin, affect the overall performance, poor compatibility, etc., and achieve the effect of expanding the research scope and application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolution of emulsifier: Take 1.25g ethylene-maleic anhydride copolymer purchased from Sigma-Aldich Company, put it into a beaker filled with 250ml deionized water, stir and heat up to 85°C and keep it warm for 1h until it is completely dissolved and emulsified agent aqueous solution.

[0030] Preparation of UF prepolymer: Add 5g urea and 13.51g formaldehyde solution with a mass fraction of 37% into a three-necked flask, add deionized water, stir until dissolved, adjust the pH value of the system to 8~9 with triethanolamine aqueous solution, and heat Reaction at 70°C for 1h.

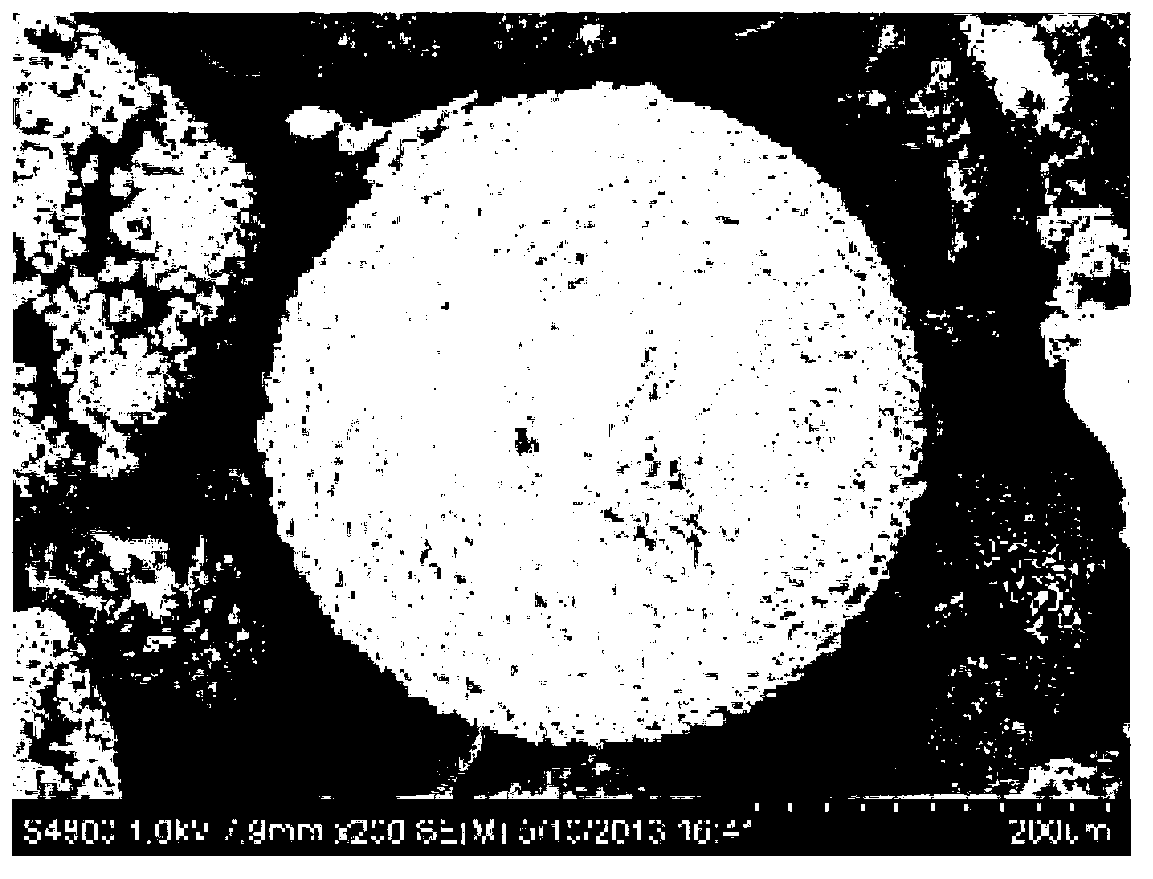

[0031] Add 0.5g of ammonium chloride and 0.5g of resorcinol to the emulsifier solution, add 12.5g of dicyclopentadiene under mechanical stirring, stir at 800rpm for 20min, and adjust the pH to 3.5. Add UF prepolymer, raise the room temperature to 55°C, react for 3 hours, filter, wash, and dry the powder obtained as self-healing microcapsules, such as figure 1 shown.

[0032] Take 0.2g of mic...

Embodiment 2

[0036] Dissolution of emulsifier: Get 2g of ethylene-maleic anhydride copolymer purchased from Sigma-Aldich, put it into a beaker filled with 250ml of deionized water, stir and heat up to 85°C and keep it warm for 1h until it is completely dissolved to obtain emulsifier aqueous solution.

[0037] Preparation of UF prepolymer: Add 7g urea and 17.1g formaldehyde solution with a mass fraction of 37% into a three-necked flask, add a certain amount of deionized water, stir until dissolved, and adjust the pH value of the system to 8~ with triethanolamine solution 9. Heat to 70°C for 1 h.

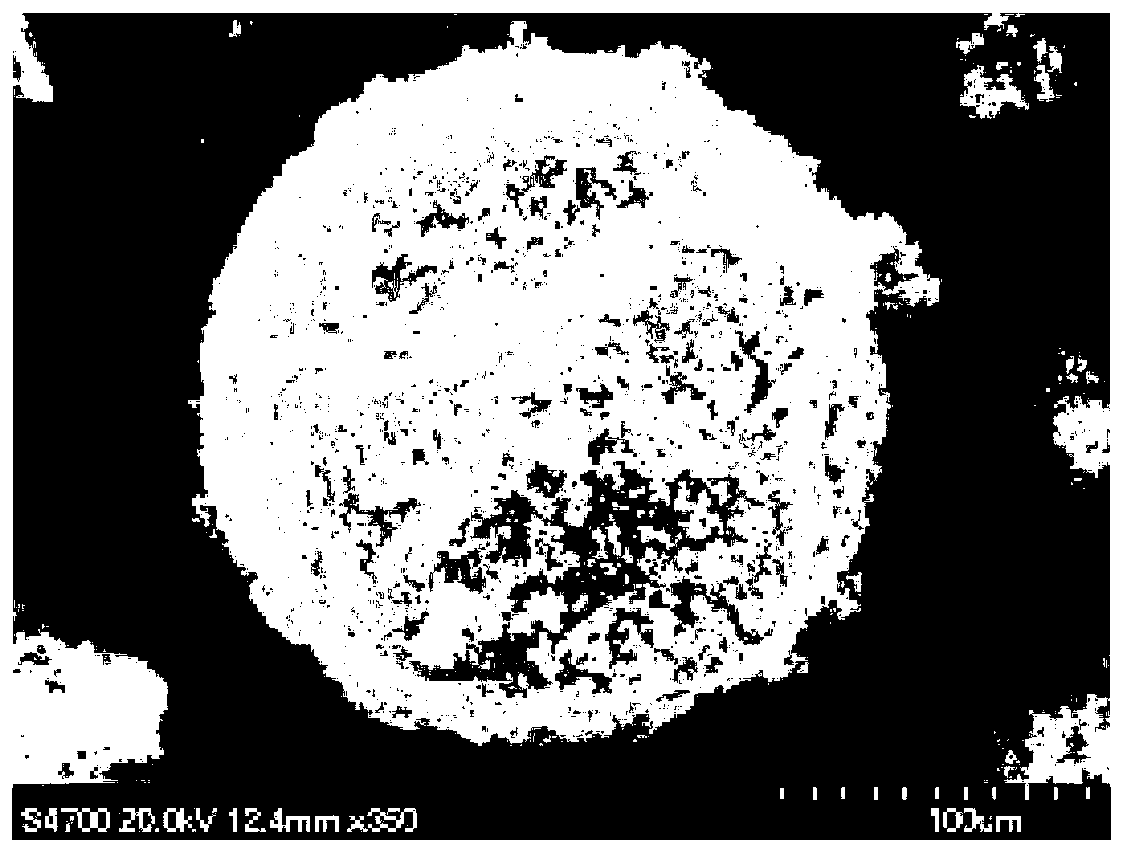

[0038] Add 0.7g of ammonium chloride and 0.7g of resorcinol to the emulsifier solution, add 10g of dicyclopentadiene under mechanical stirring, stir at 800rpm for 25min, and adjust the pH to 3.5. Add UF prepolymer, raise the room temperature to 60°C, react for 3 hours, filter, wash, and dry the powder to obtain self-healing microcapsules. Such as figure 2 shown

[0039] Take 0.5g of microcaps...

Embodiment 3

[0043] Dissolution of emulsifier: Take 2.5g of ethylene-maleic anhydride copolymer purchased from Sigma-Aldich Company, put it into a beaker filled with 250ml of deionized water, stir and heat up to 85°C and keep it warm for 1h until it is completely dissolved and emulsified agent aqueous solution.

[0044] Preparation of UF prepolymer: Add 9g urea and 19.46g formaldehyde solution with a mass fraction of 37% into a three-necked flask, add a certain amount of deionized water, stir until dissolved, and adjust the pH value of the system to 8~9, heated to 70°C for 1h.

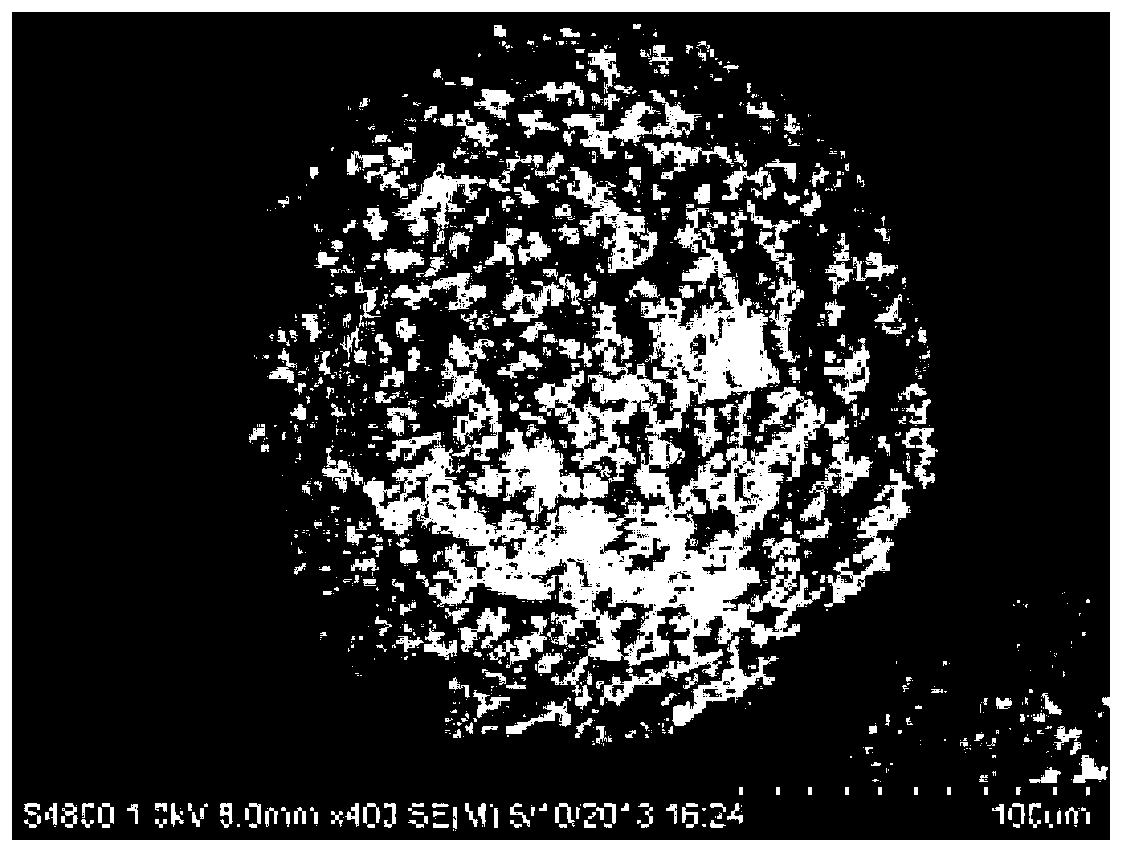

[0045] Add 0.9 g of ammonium chloride and 0.9 g of resorcinol to the emulsifier solution, add 10 g of dicyclopentadiene under mechanical stirring, stir at 800 rpm for 30 min, and adjust the pH to about 3.5. Add UF prepolymer, raise the room temperature to 65°C, react for 3 hours, filter, wash, and dry the powder to obtain self-healing microcapsules. Such as image 3 shown

[0046] Take 1g of microcapsules and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com